From 1 piece to mass production, our one-stop custom services ensure a worry-free experience for you.

Help Center

Views: 222 Author: Rebecca Publish Time: 2026-01-19 Origin: Site

Content Menu

● Core Difference: Motion, Shape, and Capability

● Part Geometry: When Milling or Turning Is Better

● Practical Differences Between CNC Milling and CNC Turning

● Typical Applications by Industry

>> Where CNC Turning Dominates

● Cost, Lead Time, and Production Volume

● Tolerances and Surface Finish

● Materials Used in CNC Milling and Turning

● When to Use Milling, Turning, or Both

● Advanced Option: Turn‑Mill and Multi‑Tasking Machines

● Practical OEM Case: Shaft with Flats and Cross‑Holes

● How CNC Milling and Turning Support Metal, Plastic, and Silicone OEM Parts

● Take the Next Step with U‑NEED

● FAQs About CNC Milling vs CNC Turning

>> 1. Which is more accurate, CNC milling or CNC turning?

>> 2. Can a single part use both milling and turning?

>> 3. Is CNC turning always cheaper than milling?

>> 4. How do I choose between milling and turning for my drawing?

>> 5. What files should OEM buyers provide for CNC machining?

For overseas OEM buyers, the key difference between CNC milling and CNC turning lies in how the material and cutting tool move and what geometries they can produce, which directly affects cost, lead time, and quality. Understanding these differences helps you choose the most suitable process for shafts, housings, brackets, connectors, and other custom parts.

CNC milling is a subtractive machining process where a rotating cutting tool removes material from a stationary or semi‑fixed workpiece to create complex 2D and 3D shapes.

- The tool rotates, while the workpiece is clamped on a table or fixture.

- Multi‑axis milling (3, 4, or 5 axes) allows machining of multiple faces in one setup.

- It is best for flat surfaces, pockets, slots, contours, and complex free‑form geometries that are not rotationally symmetrical.

Typical CNC‑milled parts include:

- Precision brackets, base plates, and housings for equipment.

- Complex manifolds, valve blocks, and fluid control components.

- Heat sinks, electronic enclosures, and custom fixtures.

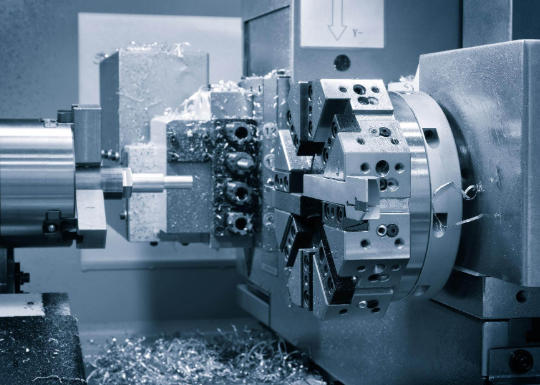

CNC turning is a lathe‑based machining process where the workpiece rotates around its axis while a stationary cutting tool removes material.

- The workpiece rotates in a chuck at high speed, while the tool feeds along or across the axis.

- It is ideal for cylindrical or conical parts and features requiring precise diameters.

- Turning delivers excellent surface finishes and tight dimensional control on round features.

Typical CNC‑turned parts include:

- Shafts, pins, bushings, sleeves, and rollers.

- Threaded connectors, couplings, and pipe fittings.

- Discs, flanges, and pulleys.

The fundamental difference between CNC milling and CNC turning is whether the tool or the workpiece rotates, which determines the shapes each process handles best.

- CNC milling:

- A rotating multi‑point cutting tool moves around a largely stationary workpiece.

- Cutting is intermittent as tool teeth engage and disengage the material.

- CNC turning:

- The workpiece rotates, and a single‑point tool remains stationary relative to the spindle axis.

- Cutting contact is continuous along the circumference of the part.

Choosing the right process starts with the geometry of the part.

Use turning when:

- Parts are round, cylindrical, or conical, such as shafts, rods, and sleeves.

- Features require precise diameters, concentricity, or long axial lengths.

- Threads, grooves, or chamfers are needed around a central axis.

Use milling when:

- Parts are non‑rotationally symmetrical, such as plates, blocks, or complex 3D forms.

- Features include slots, pockets, cavities, steps, and surface patterns.

- Multiple faces require machining with different orientations.

| Factor | CNC Milling | CNC Turning |

|---|---|---|

| Motion principle | Rotating tool, mostly fixed workpiece | Rotating workpiece, stationary tool |

| Ideal geometry | Complex, prismatic, non‑round shapes | Cylindrical, conical, rotational parts |

| Tool type | Multi‑point end mills, drills, form tools | Single‑point turning tools and inserts |

| Surface finish | Excellent on flat/prismatic faces with proper parameters | Superior finish on diameters and concentric surfaces |

| Tolerances | Tight tolerances; more setups for complex parts | Very tight diametral tolerances and strong concentricity |

| Setup time | Higher for multi‑face machining and complex fixturing | Faster for repeatable round parts |

| Typical volumes | Low‑ to medium‑volume and prototypes with complex geometry | Medium‑ to high‑volume cylindrical parts |

| Typical materials | Metals, plastics, composites with high versatility | Metals and plastics, very efficient for steels and alloys |

| Common parts | Brackets, housings, manifolds, plates | Shafts, bushings, rings, threaded fittings |

Both CNC milling and CNC turning are essential across automotive, aerospace, medical, consumer electronics, and industrial equipment, but they serve different roles.

- Automotive: Drive shafts, steering components, spacers, engineered fasteners.

- Aerospace: Hydraulic shafts, couplings, precision bushings.

- Medical: Bone screws, surgical fasteners, implant pins and rods.

- Industrial machinery: Machine bases, brackets, mounting plates.

- Electronics: Enclosures, heat sinks, precision structural frames.

- Robotics and automation: Custom end‑effectors, sensor mounts, structural modules.

For OEM projects, cost per part and lead time are heavily influenced by the chosen process and production quantity.

- Turning is often more cost‑effective for high‑volume production of round parts due to faster cycle times and simpler setups.

- Milling is typically preferred for prototyping and low‑ to medium‑volume runs where geometries are complex.

- Complex milled parts with multiple setups can increase fixture costs, machine time, and programming effort.

For many parts, the optimal strategy is combining both turning and milling, especially for components that have both cylindrical and prismatic features.

Choosing between milling and turning also depends on the required tolerances and surface quality.

- CNC turning:

- Achieves very smooth finishes on cylindrical surfaces thanks to continuous cutting.

- Ideal when tight fits are needed on bearing seats, shafts, and threaded interfaces.

- CNC milling:

- Delivers tight tolerances on flat and complex features with proper tooling, fixturing, and cutting parameters.

- Multiple setups may be required for 5‑sided or 3D profiles, which must be controlled to maintain accuracy.

Both processes support a wide range of metals, plastics, and composite materials, with some typical tendencies.

- Metals: Aluminum, stainless steel, carbon steel, brass, copper, and high‑strength alloys are common in both processes.

- Plastics: ABS, POM, PEEK, nylon, and other engineering plastics are frequently milled or turned for functional prototypes and end‑use components.

- Turning is often preferred for harder metals and dense alloys when the part is rotational, while milling handles complex shapes in both metals and plastics effectively.

For OEM and brand owners, a simple decision framework helps match your drawing to the right process.

1. Analyze part geometry

- Mostly round, with one main axis → prioritize CNC turning.

- Non‑symmetrical, multiple faces, pockets → choose CNC milling.

2. Check critical features

- Tight diameters, threads, long shafts → turning.

- Complex pockets, 3D profiles, multi‑face features → milling.

3. Consider production volume

- Large batches of similar round parts → turning for best cost and consistency.

- Mixed parts, prototypes, or custom assemblies → milling or a milling–turning combination.

4. Evaluate surface and tolerance needs

- Superior surface finish on cylinders → turning.

- Tight tolerances on complex shapes → multi‑axis milling.

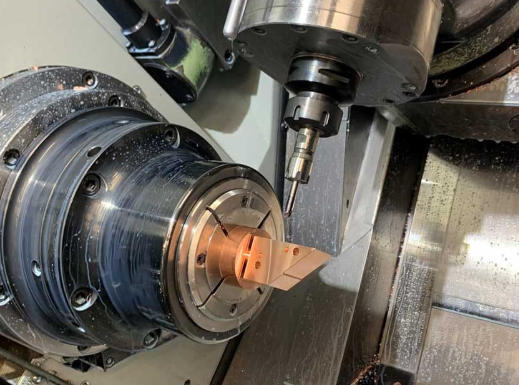

Modern hybrid turn‑mill centers can perform both turning and milling operations in a single setup, significantly improving efficiency.

- The part is clamped once, then all cylindrical and prismatic features are machined in sequence.

- This reduces handling time, setup error, and overall lead time, and improves throughput in demanding production environments.

For OEM customers, this brings:

- Better positional accuracy between diameters, slots, and cross‑holes.

- Lower risk of misalignment between turned and milled features.

Many real‑world parts require both processes in one workflow.

- Step 1: Turning creates the main shaft diameters, shoulders, and threads on a lathe.

- Step 2: Milling adds wrench flats, keyways, slots, and cross‑holes on a machining center.

Using a hybrid or multi‑tasking machine, both steps can be combined to ensure higher accuracy and shorter lead times for multifunctional components such as drive shafts, tool holders, and precision rollers.

For international buyers working with an integrated Chinese OEM like U‑NEED, combining machining with plastics and silicone manufacturing unlocks flexible product development.

- Precision metal parts: Shafts, bushings, housings, and connectors produced by CNC turning and milling, ready for assembly into your systems.

- Plastic components: Machined engineering plastics for prototypes or low‑volume runs, plus molded parts for mass production and consumer products.

- Silicone and soft components: Molded silicone seals, gaskets, keypads, and protective covers that assemble with machined metal and plastic parts.

A single supplier that can handle high‑precision machining, plastic products, silicone products, and metal stamping helps ensure consistent quality, reduced communication cost, and smoother project management for overseas brands and manufacturers.

If you are a brand owner, wholesaler, or manufacturer looking for a reliable partner for high‑precision machined parts, plastic components, silicone parts, and metal stamping, U‑NEED is ready to support your projects from concept to mass production. Send your 2D drawings, 3D models, and project details, including materials, quantities, and target markets, and the engineering team will recommend the optimal combination of CNC milling, CNC turning, molding, and stamping for your parts. Contact U‑NEED today to discuss your next project and receive a tailored quotation and manufacturability review.

Contact us to get more information!

Both processes can achieve tight tolerances, but turning usually offers better accuracy and surface finish on cylindrical features because the workpiece rotates and cutting is continuous. For flat or complex 3D surfaces, well‑configured milling machines can also achieve very high precision.

Yes. Many parts such as shafts with wrench flats, cross‑holes, grooves, or mounting faces require turning for the round features and milling for prismatic details. Using both processes, or a turn‑mill machine, often provides the best balance of cost, accuracy, and functionality.

Not always. Turning is often more economical for high‑volume production of simple cylindrical parts, where cycle times are short and setups are repeatable. Milling can be more cost‑effective for low‑volume orders and prototypes that require complex, non‑round geometries.

Start by checking the main geometry. If the part is mainly round with one central axis, turning is usually the primary process. If the part is a plate, block, or complex 3D shape with many faces, pockets, and profiles, milling is typically the better choice, potentially combined with limited turning where needed.

Ideally, provide dimensioned 2D drawings together with 3D CAD files, material specifications, tolerance requirements, surface finish expectations, and estimated order quantities. This information allows your manufacturing partner to recommend the right process, optimize costs, and quote accurate lead times.

1. https://jlccnc.com/blog/cnc-milling-vs-cnc-turning

2. https://mssp.group/what-is-the-difference-between-cnc-milling-and-cnc-turning/

3. https://www.komacut.com/blog/cnc-milling-vs-cnc-turning/

4. https://waykenrm.com/blogs/cnc-turning-and-milling/

5. https://www.ptsmake.com/what-is-the-difference-between-cnc-milling-and-cnc-turning/

6. https://www.facturee.de/en/cnc-milling-vs-cnc-turning-which-process-is-the-right-one-for-your-project/

7. https://www.unionfab.com/blog/2023/09/cnc-milling-vs-turning-processes-applications-pros-cons

8. https://hmaking.com/cnc-turning-vs-cnc-milling-how-to-choose-for-your-part/

9. https://eglvaughan.co.uk/difference-between-cnc-turning-and-milling/

10. https://www.autodesk.com/products/fusion-360/blog/cnc-miling-or-cnc-turning/

11. https://www.acemicromatic.net/cnc-milling-vs-cnc-turning/

12. https://www.zintilon.com/blog/cnc-milling-vs-cnc-turning/