From 1 piece to mass production, our one-stop custom services ensure a worry-free experience for you.

Help Center

Views: 222 Author: Loretta Publish Time: 2025-12-21 Origin: Site

Content Menu

● Why CNC Machining Is Essential for Robotics

● Core Applications of CNC Machining in Robotics

>> Robotic Arm Structures and Joints

>> Robot Frames, Bases, and Housings

>> Prototyping Robotic Systems

● Robots in CNC Machining: Automated Machine Tending

>> What Is Robotic CNC Tending?

>> Key Benefits of CNC Robotics in Machining

● Types of Robots Used in CNC Robotics

>> Collaborative Robots (Cobots)

>> Future Trends: AI, Swarm Robotics, and Humanoid Systems

● Typical CNC Processes for Robotic Components

>> CNC Milling

>> EDM, Grinding, and Special Processes

● Common Materials for CNC Robotics Projects

● Design Tips for CNC Machined Robot Parts

● CNC Robotics vs. Traditional CNC Machining

● How to Start a CNC Robotics Project With an OEM

● Clear Call to Action for OEM Buyers

>> 1: What is the difference between CNC machining and CNC robotics?

>> 2: Why is CNC machining preferred for robot parts instead of casting or molding?

>> 3: Can small factories benefit from CNC robotics, or is it only for large plants?

>> 4: What information should OEM buyers provide when requesting CNC robotics parts?

>> 5: How long does it take to develop CNC machined parts for a new robot?

CNC robotics combines computer-controlled machining with industrial or collaborative robots to achieve higher precision, lower labor costs, and stable 24/7 production in modern factories. For overseas brands, wholesalers, and manufacturers, understanding CNC robotics is essential both for designing robot parts and for automating CNC machining cells with a reliable OEM partner.[1][2][3]

CNC robotics refers to the integration of CNC machine tools (mills, lathes, grinders, routers) with robots for part manufacturing, loading, unloading, inspection, and assembly. It includes both CNC machining of robotic components and the use of robots to automate CNC machines, often called robotic machine tending or robotic CNC machining.[2][4][5][1]

- In “CNC for robotics”, machining is used to produce precision components such as arms, joints, frames, and end effectors for industrial robots and cobots.[6][2]

- In “robotics for CNC”, robots handle repetitive tasks like loading workpieces, repositioning parts, and post-machining operations, enabling lights-out manufacturing with minimal human supervision.[4][7]

Well-implemented CNC robotics increases throughput, improves consistency, and helps manufacturers respond quickly to new product launches or engineering changes.[3][2]

Robots demand tight tolerances, complex geometries, and reliable performance over millions of cycles. CNC machining supports these needs with a combination of high precision, material flexibility, and repeatability across small and large batches.[7][2][6]

Key reasons CNC machining is widely used in robotics:

- High precision and stability: CNC machining can achieve micrometer-level tolerances for critical joints, gear housings, and sensor mounts, ensuring smooth motion and accurate positioning.[1][2]

- Material versatility: Robots use aluminum, stainless steel, titanium, brass, and engineering plastics like PEEK and nylon, all of which can be machined efficiently with CNC processes.[6][7]

- Fast prototyping and low-volume production: For new robot models or customized grippers, CNC makes it possible to iterate quickly before moving to higher-volume processes if needed.[2][6]

For OEM buyers, using CNC machined robot parts reduces design risk and speeds up time-to-market for both industrial and service robotics.[3][6]

Robotic arms rely on lightweight yet rigid components that must balance stiffness, weight, and fatigue resistance. CNC machining is ideal for:[2][6]

- Multi-axis arm segments with internal channels for cables or cooling

- Precision bearing housings and gearboxes that control motion and torque

- Compact joint components for cobots where smooth, backlash-free movement is critical.[6][2]

These parts benefit from 3-axis, 4-axis, and 5-axis CNC machining to create complex contours and pockets without compromising strength.[7][6]

End effectors are the “hands” of a robot, including grippers, tool changers, welding torches, polishing heads, and vacuum cups. CNC machining supports:[5][6]

- Custom gripper fingers adapted to product shape and surface requirements

- Tooling plates and adapter flanges for rapid changeovers on multi-purpose robots

- High-stiffness components for force-controlled assembly and inspection tasks.[2][6]

Using CNC machined end effectors allows OEMs to offer industry-specific solutions in automotive, electronics, medical devices, and consumer products.[3][6]

Robot frames and bases must handle dynamic loads, vibrations, and safety requirements. CNC machining enables:[1][2]

- Large aluminum or steel base plates with precise flatness for stable installation

- Structural frames that integrate cable routing, mounting points, and sensor locations

- Protective housings for motors, encoders, and controllers with accurate sealing surfaces.[6][2]

For mobile robots and AGVs, machined parts ensure accurate alignment of wheels, sensors, and drive systems.[8][6]

In R&D, CNC machining gives engineers the freedom to test new arm geometries, gear ratios, or gripper designs without investing in tooling. Typical use cases include:[2][6]

- Rapid prototypes for industrial robots, cobots, service robots, or humanoid platforms

- Low-volume runs of custom accessories or integration kits for automation projects

- Design validation before moving to casting, forging, or molding for mass production.[3][6]

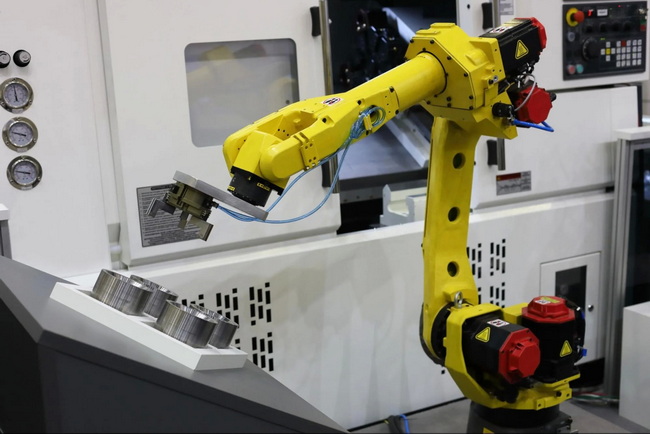

Robotic CNC tending uses an industrial robot or cobot to handle raw material, workpiece clamping, and finished parts around a CNC machine. The robot typically performs:[9][4]

- Loading billets, castings, or saw-cut blanks into CNC chucks or fixtures

- Unloading finished parts and placing them into bins, trays, or conveyor systems

- Operating machine doors, blow-off nozzles, and basic quality checks.[10][4]

This greatly reduces manual handling, improves safety, and keeps spindle utilization high during long shifts.[7][3]

Well-designed CNC robotics cells deliver strong ROI through:

- Higher uptime: Robots allow near lights-out machining at night and on weekends, maximizing machine hours without increasing headcount.[7][3]

- Consistent quality: Automated loading and clamping reduce human variation and handling damage, supporting higher repeatability.[11][12]

- Lower labor cost per part: Operators can supervise multiple robots and CNC machines instead of manually tending a single machine.[11][10]

For OEM buyers, working with a supplier that uses CNC robotics often means more stable lead times, better traceability, and fewer quality issues on complex parts.[13][3]

Traditional 6-axis industrial robots are common in high-volume CNC machining cells and can handle heavy workpieces, long reaches, and high speeds. They are often used for:[14][1]

- Machine tending between multiple CNC machines

- Palletizing and depalletizing heavy parts or fixtures

- Automated deburring, grinding, and polishing.[5][10]

These robots usually operate inside safety cages or with advanced safety systems to protect nearby workers.[15][1]

Collaborative robots, or cobots, are designed to safely share workspace with humans thanks to force-limited joints, advanced sensors, and intuitive programming interfaces. In CNC shops, cobots are used for:[16][11]

- Light-duty machine tending on mills, lathes, and grinders

- Flexible production cells where setups change frequently

- Semi-automated assembly or inspection near CNC machines.[10][11]

Cobots allow smaller factories to adopt CNC robotics without major safety fencing or complex integration projects.[12][11]

Emerging technologies such as AI-enhanced CNC robotics, swarm robotics, and humanoid robots are pushing automation further.[17][7]

- AI and machine learning enable easier robot programming, tool-wear prediction, and real-time optimization of CNC cells.[17][7]

- Swarm and mobile robots can coordinate logistics, material flow, and inspection in large factories, while humanoid platforms are being tested in human-centric environments.[8][3]

For OEM buyers, these trends suggest that more suppliers will adopt intelligent, flexible automation in the coming years.[15][17]

CNC milling is widely used for robot arms, brackets, bases, housings, and structural parts. Key capabilities include:[6][2]

- 3-axis milling for flat plates, pockets, and basic contours

- 4-axis and 5-axis milling for complex 3D surfaces, undercuts, and multi-side machining in a single setup.[7][6]

5-axis machining is especially valuable for robot accessories and complex joint housings that would otherwise require multiple fixtures.[6][7]

CNC turning is ideal for shafts, bushings, spacers, and cylindrical housings used in robotics. Combining turning with live-tool milling allows:[2][6]

- Complete machining of shaft features, keyways, and threads in one operation

- High concentricity and surface finish on mating bearing and seal surfaces.[1][2]

These parts directly impact robot motion quality, lifetime, and noise level.[3][6]

Wire EDM and sinker EDM are used when robot parts have tight internal corners, narrow slots, or very hard materials. Additional processes often combined with CNC for robotics projects include:[2][6]

- Grinding for ultra-smooth bearing or sealing surfaces

- Surface treatments like anodizing, hard anodizing, plating, or painting

- Heat treatment to achieve required hardness and fatigue strength.[7][6]

Robotics components typically combine strength, stiffness, wear resistance, and weight optimization. Popular materials include:[6][2]

- Aluminum alloys (e.g., 6061, 7075) for arms, frames, brackets, and housings where low weight and machinability are essential.[7][6]

- Stainless steels (e.g., 304, 316) for corrosive or hygienic environments, such as food processing or medical robotics.[2][6]

- Tool steels and alloy steels for gears, shafts, wear parts, and high-load structural elements.[6][2]

- Titanium for high-strength, lightweight applications in aerospace or high-performance robots.[7][6]

- Engineering plastics such as PEEK, Delrin, and nylon for insulating components, low-friction guides, or low-weight coverings.[2][6]

Selecting the right material early in the design phase helps ensure an optimal balance of cost, performance, and manufacturability.[6][7]

To get the best price and quality from CNC robotics suppliers, engineers should follow Design for Manufacturing (DFM) principles. Useful design tips include:[2][6]

- Avoid extremely thin walls or deep, narrow pockets that are hard to machine and prone to vibration.

- Use standard hole sizes, thread types, and fillet radii where possible to simplify tooling and reduce cycle time.

- Combine functions in a single machined part if it reduces assembly steps without making machining excessively complex.[7][6]

Providing clear 3D models, 2D drawings with tolerances, and surface finish requirements will reduce quoting time and prevent misunderstandings.[5][6]

Aspect | Traditional CNC Only | CNC Robotics Integrated |

Labor usage | Manual loading and operation by machinists. | Automated loading, operators supervise cells. |

Uptime | Limited by shift and operator availability. | High uptime, including night shifts and weekends. |

Consistency | More variation between operators and shifts. | Highly consistent handling and cycle times. |

Investment level | Lower initial cost for basic CNC setups. | Higher upfront cost, better long-term ROI. |

Best use case | One-off jobs and very low volumes. | Repeat parts, stable workflows, and growth plans. |

This comparison helps buyers quickly see how CNC robotics changes productivity, quality, and cost structure.

A structured approach reduces risk when outsourcing robotics parts or automated CNC machining.

Clarify robot or CNC cell functions, target cycle time, expected annual volume, and quality standards. Specify materials, key tolerances, and special finishes for each part so suppliers can plan suitable processes.[5][2]

Provide 3D CAD files and 2D drawings with clear dimensioning, GD&T symbols, and surface finish callouts. Indicate critical dimensions, reference surfaces, and inspection points to guide process control and quality checks.[5][6]

Evaluate CNC capabilities, automation experience, certifications, and sample quality. Check whether the supplier already serves robotics, automation, or high-precision industries similar to your application.[13][3]

Start with prototypes or a small batch to validate quality, communication, and logistics. Use feedback from pilot parts to fine-tune design, tolerances, and packaging before scaling to volume production.[6][7]

This step-by-step process supports long-term, stable collaboration between OEM buyers and CNC robotics manufacturers.

For overseas brands, wholesalers, and manufacturers planning new robot platforms or automated CNC cells, partnering with a specialized CNC robotics manufacturer can significantly improve competitiveness in 2025 and beyond. By combining advanced multi-axis CNC machining with practical automation experience, the right OEM partner helps reduce cost per part, shorten development cycles, and stabilize quality across global projects.[15][3][7]

If your team is evaluating suppliers for robotic arm components, end effectors, housings, or automated CNC machining solutions, now is the moment to organize your drawings, material specifications, and annual volume estimates and send a complete RFQ package. A professional CNC robotics partner can review your design, suggest manufacturability improvements, propose suitable materials and processes, and provide a detailed quotation to support your next robotics or automation program.[3][5][6][2]

CNC machining is a manufacturing process that removes material from a workpiece using computer-controlled tools, typically based on programmed G-code. CNC robotics refers to the integration of CNC machines and robots, either for machining robot components or for using robots to automate CNC operations such as loading, unloading, and inspection.[4][1][6][2]

CNC machining offers higher dimensional accuracy, shorter lead times, and easier design changes than casting or molding, especially for complex, low- to medium-volume robotics components. For early-stage projects and custom automation, CNC avoids expensive tooling while still delivering strong mechanical performance and surface quality.[7][6][2]

CNC robotics is increasingly accessible to small and medium-sized factories thanks to modular systems and collaborative robots. Even a single cobot tending one or two CNC machines can significantly reduce labor per part, stabilize throughput, and free skilled machinists for higher-value tasks.[16][11][12]

OEM buyers should supply 3D models, 2D drawings with tolerances, material specifications, surface finishes, and estimated volumes for each part. Indicating critical surfaces, mating interfaces, and functional requirements helps the supplier optimize processes, control quality, and quote more accurately.[5][6][2]

Lead time depends on complexity and quantity, but functional prototypes for robot parts can often be machined within days to a few weeks once designs are finalized. After validation, batch production can be scheduled with predictable timelines, especially when supported by automated CNC cells and standardized tooling.[3][6][7][2]

[1](https://www.robotics247.com/article/cnc_robotics_understanding_basics)

[2](https://www.fictiv.com/articles/cnc-robotics-technologies-key-trends-explained)

[3](https://www.sahilcnc.com/technical-press-news/cnc-machining-in-2025-what-s-changing-in-the-industry/)

[4](https://www.rotec-ltd.com/what-is-robotic-cnc-machining)

[5](https://www.automationwithinreach.com/blog/guide-to-cnc-robotics)

[6](https://www.3erp.com/blog/cnc-robotics/)

[7](https://www.norck.com/blogs/news/top-cnc-machining-tools-advancements-transforming-manufacturing-in-2025)

[8](https://yijinsolution.com/news-blog/humanoid-robots-in-manufacturing/)

[9](https://howtorobot.com/expert-insight/cnc-robots)

[10](https://www.devonics.com/post/cnc-collaborative-robots)

[11](https://standardbots.com/blog/guide-to-cobot-machine-tending)

[12](https://cobot.systems/cnc-machine-tending-cobot-roi/)

[13](https://cncmachines.com/2025-trends-robotics-automation-cnc-machine-shops)

[14](https://rozum.com/cnc-robotics-in-automation/)

[15](https://www.cncyangsen.com/cnc-automation-trends-in-2025)

[16](https://www.wiredworkers.io/cobot/applications/machine-tending/)

[17](https://www.automationwithinreach.com/blog/innovations-in-cnc-robotics)

[18](https://standardbots.com/blog/what-is-a-cnc-robot-everything-these-machines-can-do)

[19](https://www.siemens.com/us/en/industries/solutions-for-machine-builders/machine-tools/cnc4you/technologies/cnc-robotics.html)

[20](https://tirapid.com/cnc-robotics/)

[21](https://www.productiverobotics.com/post/what-are-the-benefits-of-cobots-in-cnc-machine-shops)