Cylinder Core

Custom Plastic Moulding

Core Insert

Product Description

Compared with other molds of package products, cosmetic mold has higher requirements on appearance, especially the mould for some custom lipstick tubes, custom mascara tubes and transparent cap, etc.

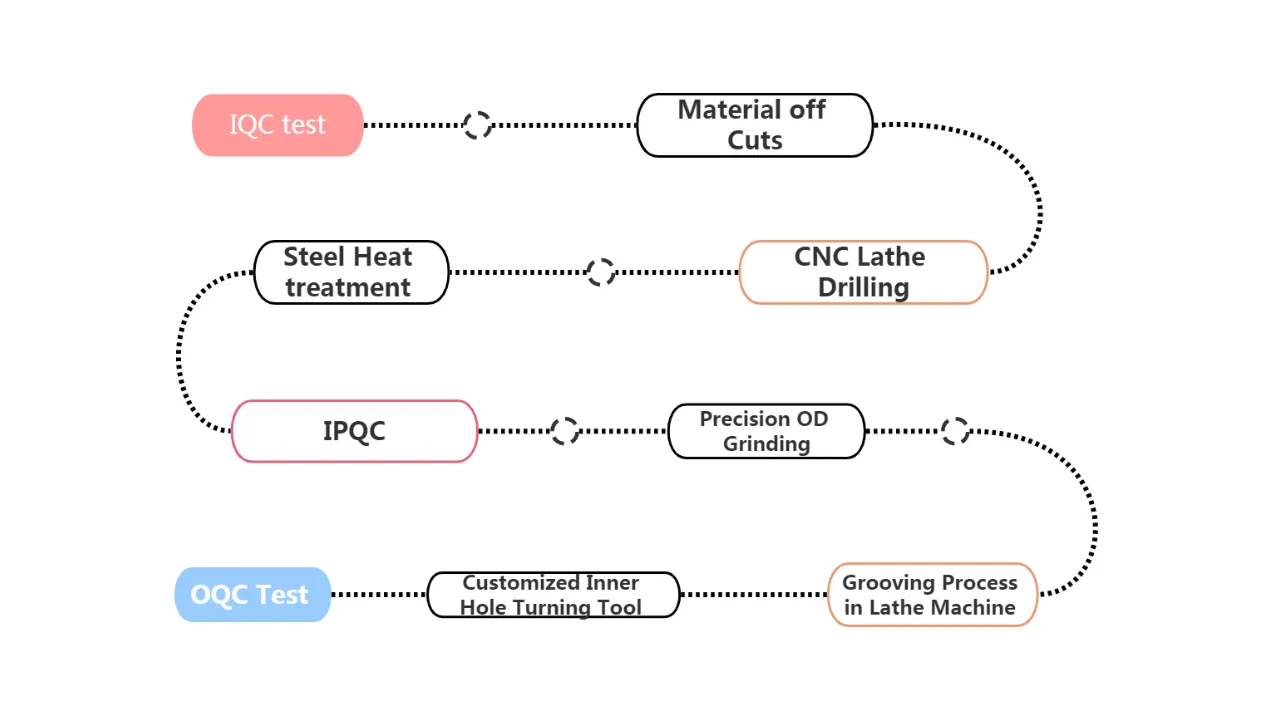

The “core” is the separate and replaceable part of the mold that forms an internal feature of the casting. As the heart of the mould, the quality, surface finish and fit of the mold cavity and core directly affect the quality of the mold.

U-NEED’s advanced molding machines are explicitly designed for the insert injection molding process. The insert molding process necessitates extremely strict tolerances to ensure the proper formation of the plastic molded parts. Our state-of-the-art insert molding equipment can meet your most exacting specifications.

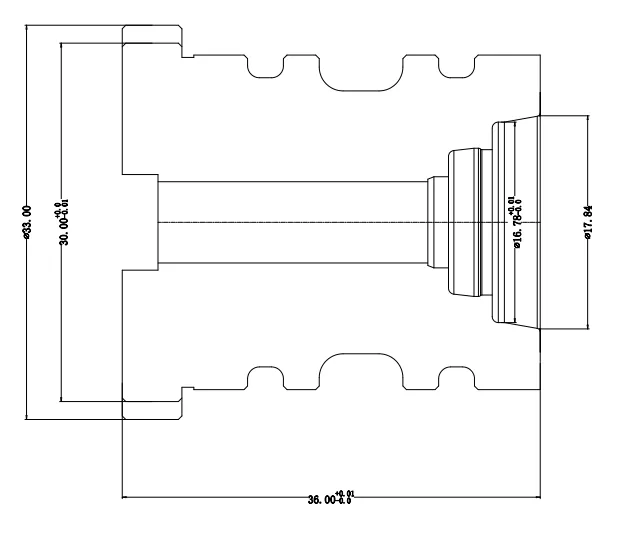

Product Details

| Material | 1.2379 to steel/ SKD11/steel D2/ Cr12Mo1v1 |

| Hardness | HRC55-57 |

| Overall dimension | Φ33*36*Φ17.84 |

| Tolerance | ± 0.01 or Customized |

| Roughness | Ra0.8 or Customized |

| Surface treatment | / |

| Quality Assurance | Full scope inspections |

| Testing Equipment | Digimatic Caliper, Micrometer tool, Digital Height Gauge, Coordinate Measurement Machine |

Drawing & Production Procedures

Application of the Turning Parts

Lipstick Tube

Mascara Tube

Eyeshadow Case

Blusher Box

Liquid Foundation Bottle

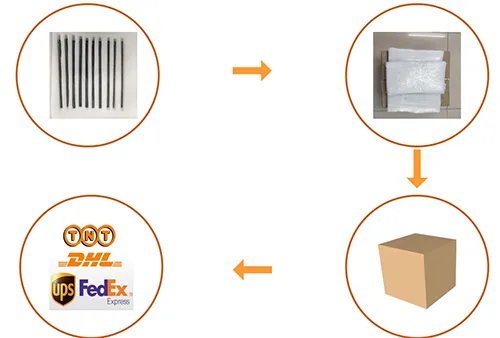

Packaging & General Terms