Product Description

The temperature in the mold production process continues to rise, and the water ensures that the mold is produced at a constant temperature to ensure the stability of the product. In order to achieve a better cooling effect, plastic mold design always needs to drain near the glue location.

The brass cooling water diverter divides the water into two parts to form a waterway, which takes away the heat of the mold and allows the mold temperature to be cooled.

Product Details

| Material | Bronze material |

| Hardness | Whithout heat treatment (The hardness of raw material about HRC20) |

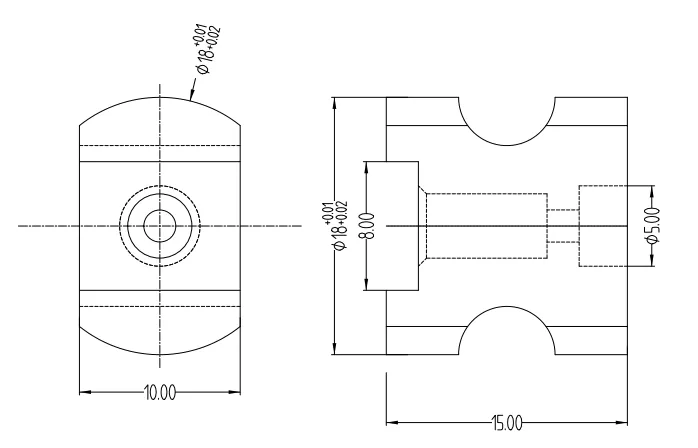

| Overall dimension | Φ18*10*15mm |

| Tolerance | ±0.02 or Customized |

| Roughness | Ra1.2 or Customized |

| Surface treatment | / |

| Quality Assurance | Full scpe inspections |

| Testing Equipment | Digimatic Caliper,Micrometer tool,Digital Height Gauge,Profile Projector |

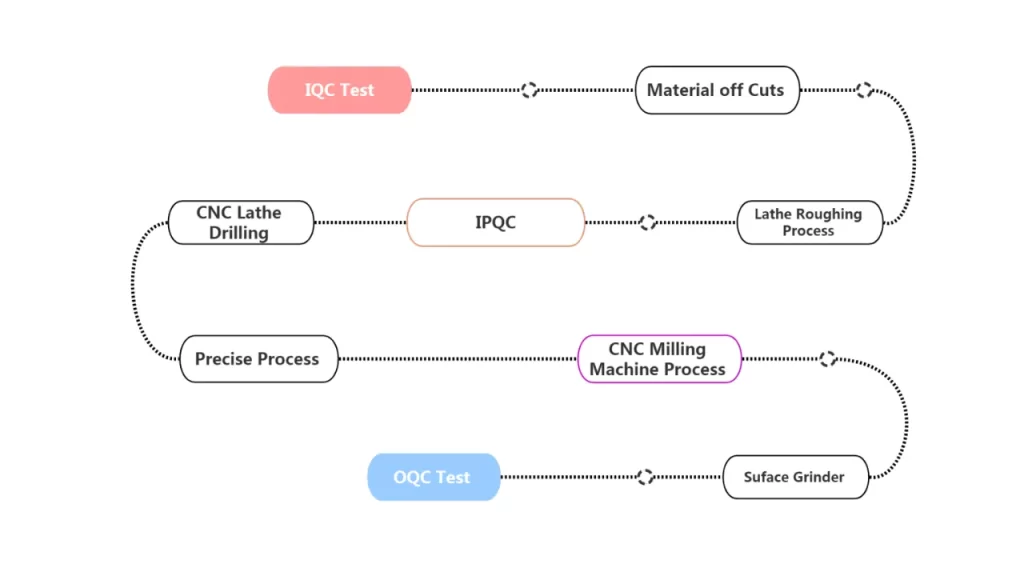

Drawing & Production procedures

Advantages

It plays a vital role in the mould cooling water system.

The water flow is relatively uniform, and cooling effect is obvious, to ensure product quality and production efficiency.

The cooling water diverter is made of brass, anti-rust and anti-corrosion, so no blockage of cooling holes is produced.