From 1 piece to mass production, our one-stop custom services ensure a worry-free experience for you.

Help Center

Views: 222 Author: Rebecca Publish Time: 2026-02-07 Origin: Site

Content Menu

● What You Will Learn in This Guide

● Key Factors for CNC Machining Metals

>> 3. Coolant, Lubrication, and Chip Control

● Understanding Machinability and Why It Matters

● Steel CNC Machining: Strength Meets Strategy

>> CNC Machine Requirements for Steel

>> Machining Carbon Steel vs Stainless Steel

>> Typical Steel Applications in CNC

● Aluminum CNC Machining: Speed and Precision

>> Process Benefits of Aluminum

>> Best Practices for CNC Machining Aluminum

>> Common Aluminum Alloys and Uses

● Copper and Brass: Soft Metals, Sharp Challenges

● Quick Comparison: Machinability and Performance by Metal

● Do CNC Metal Cutter Machines Differ by Material?

● Practical Process Tips by Metal Type

>> Aluminum Machining Checklist

● When to Involve an Expert OEM Partner

● Call to Action: Work with U-NEED for Multi‑Metal CNC Projects

● FAQs about CNC Machining Different Metals

>> 1. How do I choose the right metal for CNC machining?

>> 2. Why is aluminum so popular for CNC machining?

>> 3. Is stainless steel too difficult or expensive to machine?

>> 4. When should I use brass instead of copper?

>> 5. Can one CNC supplier handle multiple metals and processes?

CNC machining metals is not just about having a powerful machine; it is about understanding how each metal behaves under cutting forces, heat, and vibration, then tuning your process accordingly. When you match the right material with the right tooling, parameters, and coolant strategy, you get stable cycles, predictable tool life, and consistent surface finishes from prototype to mass production.

By the end of this article, you will be able to:

- Identify the strengths and challenges of steel, aluminum, copper, and brass in CNC machining.

- Choose suitable CNC machines, tooling, and cutting parameters for each metal.

- Understand machinability scores and what they mean for cycle time and cost.

- Apply practical process tips to reduce chatter, tool wear, and thermal problems.

- Know when to partner with an OEM supplier like U-NEED for complex or multi‑material projects.

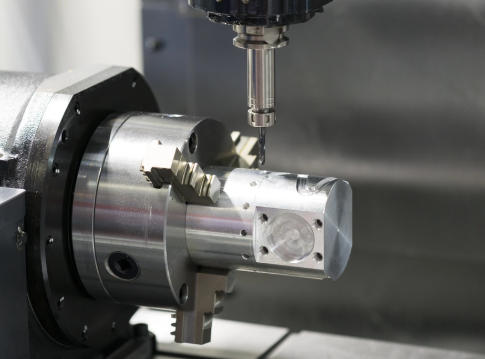

Modern CNC mills, lathes, turning centers, and routers are capable of cutting a wide range of metals, from soft aluminum and brass to hardened steels and specialty alloys. The key limitations are machine rigidity, spindle power and torque, and how well the machine can handle heat and chip evacuation.

Even lighter-duty or desktop CNC machines can cut metals if you:

- Use sharper tools with appropriate coatings.

- Reduce depth of cut and feed rates to stay within machine stiffness limits.

- Apply mist or flood coolant and clear chips frequently.

Industrial CNC machining centers, on the other hand, are designed to maintain tight tolerances and high productivity on tougher metals by combining rigid cast-iron structures, high-torque spindles, and advanced coolant systems.

Cutting tools for metal machining are typically solid carbide or indexable carbide inserts, often with heat‑resistant coatings such as TiN, TiAlN, or AlTiN. These coatings improve hot hardness, reduce friction, and extend tool life, especially in steels and high-temperature alloys.

When to adjust tooling:

- Steel and stainless steel: Prefer coated carbide for heat and wear resistance.

- Aluminum: Use polished, sharp tools and aluminum‑specific geometries to reduce built‑up edge; many applications benefit from uncoated or special low‑friction coatings.

- Copper and brass: Very sharp tools are important, and uncoated carbide often works well to avoid built‑up edge and gumming.

Cutting parameters are a balance between metal hardness, machinability, and heat generation. In general:

- Tougher metals require lower cutting speeds and higher torque.

- Free‑machining metals allow higher speeds and feeds, shortening cycle times.

As a rule of thumb:

- Steel and stainless steel: Moderate speeds, controlled feed, aggressive coolant.

- Aluminum and brass: Higher speeds and feeds, with strong chip evacuation.

- Copper: Moderate speeds with careful heat management.

Coolant reduces cutting zone temperature, improves surface finish, and flushes chips away from the tool and workpiece. Poor chip evacuation can quickly destroy tools and damage part surfaces in high‑speed metal machining.

Common practices:

- Flood coolant for steels and stainless steels.

- High‑pressure coolant or air blast for deep pockets and high‑speed machining.

- Mist lubrication for some aluminum and brass operations, especially on routers.

Machinability is the relative ease with which a material can be cut by machining processes such as milling and turning. It is often expressed as a percentage or a score referenced to a standard free‑cutting steel.

Materials with higher machinability:

- Require less cutting force.

- Allow higher cutting speeds.

- Generate better surface finishes with less tool wear.

Materials with lower machinability:

- Need more rigid setups and optimized toolpaths.

- Run at lower speeds to avoid excessive heat and tool failure.

- May demand premium tooling and coatings to maintain tool life.

For engineers and buyers, understanding machinability helps estimate production cost, choose suitable machines, and set realistic lead times.

Steel is one of the most widely machined metals, used for structural components, gears, tooling, and high‑load mechanical parts. Its strength and versatility come with challenges such as higher cutting forces and heat generation.

To machine steels efficiently, a CNC machine should have:

- High spindle torque at low to medium RPM.

- Rigid structure and robust linear guides to resist deflection.

- Secure workholding to avoid vibration and chatter.

- Flood coolant or high‑pressure systems to handle heat.

These capabilities are particularly important for stainless steels and hardened grades where tool wear accelerates rapidly.

- Carbon steel

- Better machinability than many stainless grades.

- Suited for shafts, brackets, and general mechanical parts.

- Standard coated carbide performs well with appropriate feeds and speeds.

- Stainless steel

- Offers excellent corrosion resistance and strength but tends to work‑harden if cutting conditions are poor.

- Requires sharp tools, adequate chip load, and consistent engagement to prevent rubbing and hardening.

- Often benefits from reduced radial engagement and constant‑chip‑load toolpaths.

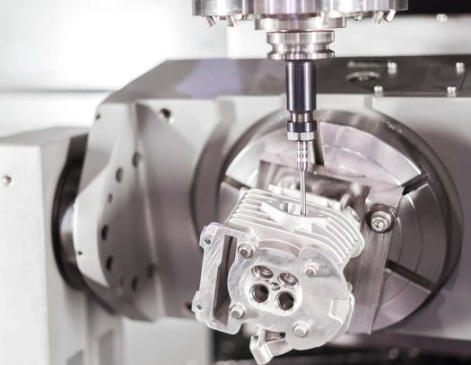

- Machine tool components, jigs, and fixtures.

- Automotive shafts, flanges, housings.

- Industrial equipment and fasteners.

For overseas brands and OEMs, choosing a partner experienced in steel CNC machining is crucial for balancing durability, tolerances, and cost across multiple batches.

Aluminum is one of the most popular metals for CNC machining because it combines low weight with good strength, corrosion resistance, and excellent machinability. Many aluminum alloys allow very high spindle speeds and aggressive feeds while maintaining tight tolerances and fine surface finishes.

- High machining speeds shorten cycle time and reduce cost per part.

- Good thermal conductivity helps dissipate heat from the cutting zone.

- Tool wear is generally lower than when machining steels and titanium.

However, aluminum chips can stick to cutting edges and cause built‑up edge, especially at lower cutting speeds or with unsuitable tool geometries. This leads to rough surfaces and premature tool failure if not controlled.

- Use high RPMs with appropriate chip load to minimize rubbing and built‑up edge.

- Apply air blast or coolant to evacuate chips from deep pockets and slots.

- Choose aluminum‑specific end mills with polished flutes and sharp edges.

- Consider anodizing or other surface treatments to improve corrosion resistance and appearance on finished parts.

- 6061: Good strength, machinability, and anodizing response; used in fixtures, brackets, housings, and general structural parts.

- 7075: Higher strength and fatigue resistance for aerospace, motorsport, and other high‑performance applications.

For OEM buyers, aluminum is often the first choice for lightweight prototypes, enclosures, and precision components where speed and cost efficiency are important.

Copper and brass belong to the same material family but behave quite differently during CNC machining. Both offer excellent electrical and thermal conductivity, making them ideal for electrical, electronic, and fluid‑handling components.

Copper's high thermal conductivity and ductility make it prone to gumming tools and generating heat at the cutting edge. If speeds are too high or tools are dull, edges can smear and surfaces can burnish instead of cutting cleanly.

Recommended practices:

- Use very sharp, uncoated or low‑friction tools to maintain shearing action.

- Keep speeds moderate and chip load sufficient to avoid rubbing.

- Apply consistent coolant to remove heat and flush chips.

Typical applications:

- Busbars and electrical connectors.

- Heat sinks and thermal management components.

- Plumbing and HVAC fittings.

Brass is considered one of the most machinable engineering metals, with machinability ratings significantly higher than many steels. It cuts cleanly, forms short chips, and usually produces excellent surface finishes with minimal burrs.

Advantages of brass in CNC machining:

- Low tool wear and stable cutting forces.

- High permissible cutting speeds, improving throughput.

- Good corrosion resistance and attractive appearance for visible components.

Typical applications:

- Precision fittings and valves.

- Decorative hardware and consumer products.

- Electrical and electronic components.

For cost‑sensitive projects, brass offers an attractive balance of machinability, durability, and appearance, especially when large quantities of small turned or milled parts are involved.

| Metal | Tool Wear Level | Typical Machining Speed | Surface Finish Quality | Approx. Machinability Score* |

|---|---|---|---|---|

| Steel | High | Moderate | Good | 5/10 |

| Aluminum | Low | High | Excellent | 9/10 |

| Copper | Medium | Low–Moderate | Fair–Good | 4/10 |

| Brass | Low | Moderate–High | Very Good | 8/10 |

Scores are indicative, reflecting relative machinability trends commonly reported in machining references.

This table shows why aluminum and brass are often selected for high‑volume CNC production, while steel and copper usually require more careful parameter selection and tool management.

The core motion system of a CNC machine may be similar, but the optimal setup can differ significantly by material.

Key differences include:

- Spindle characteristics

- Steel and stainless: Favor high torque at lower RPM.

- Aluminum and brass: Benefit from higher RPM capacity for fast material removal.

- Toolpath strategy

- Steels: Adaptive or constant‑engagement paths to control cutting forces and heat.

- Aluminum: High‑speed machining with trochoidal paths and lighter cuts at higher speeds.

- Workholding and fixturing

- Heavier cuts in steels require very rigid fixtures.

- Thin aluminum parts may need vacuum or custom soft jaws to prevent chatter and distortion.

Matching the metal to the correct machine, tooling, and CAM strategy is critical for reducing scrap and ensuring consistent quality in OEM production.

1. Start with conservative cutting speeds and increase gradually while monitoring tool wear.

2. Use coated carbide tools and ensure sufficient coolant flow.

3. Avoid rubbing in stainless by maintaining enough chip load and avoiding long dwell times.

1. Use high‑RPM spindles and aluminum‑optimized end mills.

2. Clear chips aggressively with air blast or coolant.

3. Watch for burrs on thin walls and adjust toolpath entry and exit strategies.

1. Keep tools extremely sharp and avoid dull edges.

2. Use moderate speeds with stable feed to prevent smearing.

3. Apply steady coolant to control heat and maintain surface quality.

1. Take advantage of high machinability with faster speeds and feeds.

2. Use robust workholding to maintain repeatability during high‑volume runs.

3. Optimize toolpaths for short cycle times without sacrificing finish.

Multi‑metal projects, tight tolerance requirements, and complex geometries often justify partnering with a specialized CNC supplier. An experienced OEM partner can help you:

- Select the right metal based on function, environment, and cost.

- Standardize machining parameters for repeatable quality across batches.

- Integrate CNC machining with plastic, silicone, and metal stamping processes where needed.

U-NEED is a China‑based OEM manufacturer that combines high‑precision CNC machining, plastic product manufacturing, silicone product manufacturing, and metal stamping to support overseas brands, wholesalers, and manufacturers from prototype to mass production. This integrated capability is particularly valuable for assemblies that mix metal frames, plastic housings, and silicone seals.

Choosing the right metal is only half the battle; you also need a manufacturing partner who understands how different materials behave in real production. If you are an overseas brand, wholesaler, or manufacturer looking for reliable CNC machining of steel, aluminum, copper, or brass components, plus integrated plastics, silicone, and metal stamping, U-NEED can support you from prototype through mass production.

Share your drawings, target quantities, and material preferences with the U-NEED team, and our engineers will recommend optimal metals, machining strategies, and secondary processes for your project. Contact U-NEED today to discuss your next CNC machining project and get a tailored solution that aligns with your quality, lead time, and cost targets.

Contact us to get more information!

Start from the application requirements: mechanical load, temperature, corrosion, weight, and electrical needs. Aluminum and brass are ideal when machinability and speed are priorities, while steels and stainless steels suit high‑load or harsh environments, and copper fits high‑conductivity applications.

Aluminum combines low weight, good strength, corrosion resistance, and excellent machinability, allowing high spindle speeds and short cycle times. It is widely used for enclosures, structural parts, and prototypes because it balances performance and cost better than many other metals.

Stainless steels are more challenging than many carbon steels due to hardness and work‑hardening, which can increase tooling and machining costs. However, with proper tooling, coolant, and programming, CNC shops regularly achieve tight tolerances and long‑term durability for parts in medical, food, and marine applications.

Choose brass when you need high machinability, attractive appearance, and good corrosion resistance, often in fittings, valves, and decorative parts. Use copper when maximum electrical or thermal conductivity is critical, such as in busbars, connectors, or heat‑management components.

Yes, many OEM‑focused suppliers specialize in machining multiple metals and can also integrate plastic, silicone, and stamping processes in one project. A partner like U-NEED, which combines high‑precision metal machining with plastic and silicone product manufacturing and metal stamping, can simplify your supply chain and improve consistency across complex assemblies.