From 1 piece to mass production, our one-stop custom services ensure a worry-free experience for you.

Help Center

Views: 222 Author: Rebecca Publish Time: 2026-01-21 Origin: Site

Content Menu

● What Is HP Multi Jet Fusion 3D Printing?

● How HP Multi Jet Fusion Works (Step-by-Step)

● HP Multi Jet Fusion Printer Lineup and Key Specs

>> HP Jet Fusion 5600 Series: Technical Highlights

● Speed, Throughput, and Operational Efficiency

>> Build Speed and Productivity

● Print Quality and Mechanical Performance

>> Dimensional Accuracy and Surface Detail

>> Material Properties and Isotropy

● HP Multi Jet Fusion Materials and Applications

>> Commonly Used HP MJF Materials

● Essential Post-Processing for MJF Parts

>> Standard Post-Processing Workflow

● Advantages of HP Multi Jet Fusion for Manufacturers

● Why HP MJF Is Ideal for End-Use Parts

>> Durability and Functionality

● HP MJF vs FDM: Which Should You Use?

● Practical Implementation Tips and UX Suggestions

>> Implementation Tips for Engineering Teams

● Call to Action: Start Your HP MJF Project

● FAQs About HP Multi Jet Fusion 3D Printing

>> 1. What resolution does HP Multi Jet Fusion offer?

>> 2. What is the build volume of HP Multi Jet Fusion?

>> 3. How fast is HP Multi Jet Fusion compared with other 3D printing methods?

>> 4. Which industries benefit most from HP MJF?

>> 5. What post-processing is required for HP MJF parts?

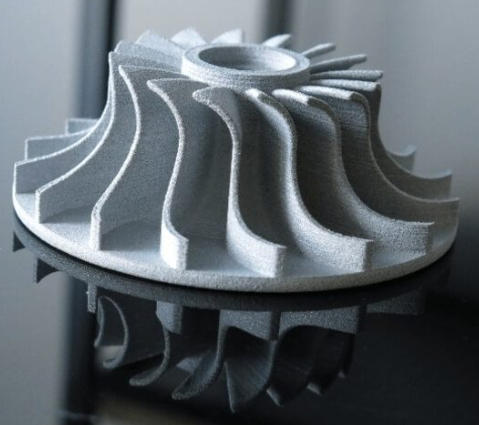

HP Multi Jet Fusion (MJF) 3D printing is a production-grade additive manufacturing technology designed for fast, repeatable, and high-quality end-use parts. It combines high print speed, fine detail, and robust thermoplastic materials, making it ideal for prototypes and low–to–medium volume production across automotive, consumer products, industrial equipment, and healthcare.

HP Multi Jet Fusion is an industrial 3D printing process that uses powdered thermoplastics, fusing agents, and infrared energy to build parts layer by layer. Compared with many legacy 3D printing methods, it emphasizes speed, dimensional accuracy, and consistent mechanical properties across all directions of the part.

- Process type: Powder-bed fusion with jetting agents and infrared fusing.

- Typical use cases: Functional prototypes, jigs and fixtures, structural housings, lightweight brackets, and fully functional end-use components.

- Key advantages: Fast build times, fine feature resolution, excellent detail, and efficient powder recycling.

For engineering teams and manufacturers, MJF bridges the gap between prototyping and production by enabling repeatable manufacturing without tooling.

Understanding how HP MJF works helps you evaluate whether it matches your application, quality, and cost targets.

1. Powder Layer Application

A recoater spreads a thin, uniform layer of polymer powder across the build platform.

- Typical layer thickness is around 0.09 mm (0.0035 in) for HP MJF 5600 systems.

- The build volume for the HP MJF platform is 380 x 284 x 380 mm (15 x 11.2 x 15 in), allowing single large parts or tightly nested batches of small parts.

2. Jetting Fusing and Detailing Agents

Inkjet arrays selectively deposit a fusing agent where the powder must solidify and a detailing agent where sharp edges and fine features are needed.

- Fusing agent drives local absorption of heat.

- Detailing agent helps control edge sharpness and surface quality.

3. Infrared Fusion

Infrared lamps pass over the powder bed, heating the fusing agent regions so the powder melts and bonds together.

- Areas without fusing agent remain loose powder, providing natural support.

4. Layer-by-Layer Build

The system repeats the cycle—spreading powder, jetting agents, and fusing—until the complete part or nested batch is finished.

5. Cooling and Depowdering

After printing, the build cools in the chamber to avoid warping and preserve dimensional accuracy. Excess powder is then removed mechanically or with air/automated systems and partially recycled.

This workflow delivers high throughput and robust mechanical performance suitable for production environments.

HP offers multiple MJF models optimized for different throughput and application needs. Selecting the right platform depends on part volume, color requirements, and production mix.

- HP Jet Fusion 5600 Series

- Optimized for high-throughput end-use production, typically 550+ parts per week.

- Designed for demanding industrial environments with tight quality and repeatability requirements.

- HP Jet Fusion 5400 Series

- Ideal for white applications, supporting final parts production at roughly 500+ parts per week.

- HP Jet Fusion 5200 Series

- Suited for production environments targeting around 200+ parts per week.

- HP Jet Fusion 500 3D Printer

- Tailored to industrial prototyping and smaller-scale final part production (up to 200 parts per week).

HP publishes detailed technical datasheets for each platform, including dimensional data, throughput projections, and environmental requirements.

For many production users, the 5600 series is the reference MJF system.

Performance and Build Space

- Effective build volume: 380 x 284 x 380 mm (15 x 11.2 x 15 in).

- Build speed: Up to 3,466 cm³/hr (211 in⊃3;/hr).

- Layer thickness: 0.09 mm (0.0035 in).

- Resolution: 1200 dpi (X–Y), enabling sharp, detailed geometries.

Physical Footprint

- Printer dimensions: 2210 x 1268 x 1804 mm (87 x 50 x 71 in).

- Recommended operating area: 3700 x 3700 x 2500 mm (146 x 146 x 99 in).

- Printer weight: 880 kg (1940 lb).

Connectivity, Hardware, and Software

- Network: Gigabit Ethernet (10/100/1000 Base‑T) with common protocols such as TCP/IP, DHCP (IPv4), and TLS/SSL.

- Controller hardware: Intel Core i7‑7770 (3.6 GHz, up to 4.2 GHz), 64 GB DDR4 memory.

- Storage: 1 TB HDD and 1 TB SSD with AES‑256 encryption, TCG‑OPAL 2.01 compliant.

- Integrated software: HP SmartStream 3D Build Manager, HP SmartStream 3D Command Center, HP 3D Center, HP 3D APO, HP 3D Process Development.

- Certified third-party tools: Autodesk® Netfabb® with HP Workspace, Materialise Build Processor, Siemens NX AM for MJF.

- Supported file formats: 3MF, STL, OBJ, VRML (v2.0).

Power Requirements

- Power consumption: ~12 kW during operation.

- Voltage: 380–415 V (line‑to‑line) at up to 50 A, or 200–240 V at up to 80 A, 50/60 Hz.

For production sites, planning around footprint, ventilation, and power capacity is essential before installation.

The HP Jet Fusion 5600 series can achieve build speeds of up to 3,466 cm³/hr (211 in⊃3;/hr), supporting rapid turnaround for both prototypes and production runs. This speed makes it significantly faster than many legacy polymer 3D printing platforms, particularly for densely packed builds.

Key contributors to productivity include:

- Calibrated print modes to balance speed and quality across different geometries.

- Automated build-unit exchange that supports continuous operation, enabling one unit to cool while another prints.

Real-world throughput will depend on part size, packing efficiency, orientation, and material selection, so process optimization is critical for cost per part.

HP MJF is engineered for end-use quality standards rather than purely cosmetic prototyping.

- Detail resolution: 1200 dpi in X and Y for crisp edges and finely featured designs.

- Surface quality: Jetting-based detailing agents and controlled fusion lead to smooth surfaces, even on complex geometries.

MJF parts typically show uniform mechanical properties in X, Y, and Z directions, which is critical for load-bearing applications. Consistent isotropy makes it easier to validate designs for automotive, consumer hardware, and industrial applications.

- Consistency: Calibrated print profiles help ensure repeatability across builds.

- Durability: Engineering-grade polymers provide strength, impact resistance, and long-term performance.

Final print quality still depends on process parameters, material choice, and downstream finishing, so engineering validation remains necessary.

Material selection determines how MJF parts behave in real-world conditions, from flexibility to heat resistance.

| Material | Key Description | Ideal Applications | Typical Finishes |

|---|---|---|---|

| PA‑11 | Tough, flexible, high impact resistance, low friction. | Gears, bearings, dynamic components that need ductility. | Dyeing, painting, coatings, electroplating, vapor smoothing. |

| PA‑12 | Tough, rigid, strong chemical resistance, low friction. | Structural housings, brackets, connectors, functional end-use parts. | Dyeing, painting, coatings, electroplating, vapor smoothing. |

| PA‑12 Full Color | Similar to PA‑12 but supports full-color printing. | Visual prototypes, presentation models, colored functional components. | Vapor smoothing. |

| PA‑12 Glass Bead | Glass-bead-filled for higher stiffness and dimensional stability. | Load-bearing brackets, fixtures, gears needing rigidity. | Dyeing, painting, coatings, electroplating, vapor smoothing. |

| Polypropylene (PP) | Lightweight, affordable, excellent chemical resistance. | Fluid reservoirs, housings, living hinges, chemical-contact parts. | Vapor smoothing. |

| TPA | Flexible, strong, good chemical resistance and toughness. | Gaskets, seals, flexible joints needing resilience. | Vapor smoothing, dyeing, painting, coatings. |

| TPU | Highly flexible, rubber-like, strong impact resistance. | Flexible seals, protective covers, wearable components. | Vapor smoothing, dyeing, painting, coatings. |

Emerging MJF materials continue to expand the application window, from flame-retardant grades to bio-compatible or ESD-safe variants, making the technology increasingly attractive for regulated industries.

Post-processing transforms freshly printed parts into production-ready components with the required surface finish and performance.

1. Cooling in the Build Chamber

Parts remain in the build unit to cool gradually, minimizing thermal stresses and warping.

2. Depowdering

Loose powder is removed with brushes, compressed air, or automated blasting systems. Recoverable powder is sieved and often blended with virgin material for future builds.

3. Surface Finishing

- Bead blasting or tumbling to clean surfaces and create a uniform texture.

- Chemical or vapor smoothing to improve surface gloss and reduce roughness.

4. Coloring and Coating

Parts may be dyed, painted, or coated for branding, aesthetics, or UV/chemical protection.

5. Thermal Treatment (Optional)

Processes like annealing can be applied to reduce internal stresses and further optimize mechanical properties.

A robust finishing workflow is critical for repeatable surface quality and dimensional control, especially for customer-facing or safety-critical parts.

HP MJF has become a strategic choice for brands seeking agile, digital production.

- High speed: MJF builds parts significantly faster than many traditional polymer 3D printing methods, especially at higher packing densities.

- High detail and precision: 1200 dpi resolution and detailing agents yield sharp features and smooth surfaces.

- Production-grade mechanical properties: MJF parts combine strength, durability, and impact resistance for real-world use.

- Material efficiency: Recyclable powder reduces waste and lowers material cost per part.

- Scalability: Ideal for low to medium production volumes, bridging the gap between prototyping and injection molding.

For organizations with frequent design changes or complex geometries, MJF dramatically shortens the design-to-market cycle.

MJF is not just for prototyping; it is designed for repeated, production-quality output.

- Cost-effectiveness at low–medium volumes: Avoids tooling costs, making it competitive with injection molding for smaller batches or frequent design revisions.

- Mass customization: Each part can be unique without adding tooling or changeover cost, supporting personalized products and complex assemblies.

- Durability: Engineering-grade materials withstand mechanical loads, abrasion, and repeated use.

- Functional prototyping: Designers can print and test near-final parts, validate performance, and move to production faster.

- Complex geometries: MJF can produce internal channels, lattice structures, and undercuts that are difficult or impossible with traditional manufacturing.

This makes MJF a strong fit for end-use components in automotive, industrial automation, consumer devices, and medical tooling.

Choosing between Fused Deposition Modeling (FDM) and HP Multi Jet Fusion requires understanding their strengths.

| Aspect | HP Multi Jet Fusion (MJF) | Fused Deposition Modeling (FDM) |

|---|---|---|

| Print process | Powder-bed fusion with jetted fusing and detailing agents plus infrared heat. | Extrusion of heated thermoplastic filament layer by layer. |

| Best for | Production-quality parts with fine details and consistent isotropic properties. | Larger, less detailed parts, basic prototypes, and low-cost fixtures. |

| Surface finish | Generally smoother, with finer features and improved detail resolution. | Visible layer lines and anisotropic strength along Z-axis. |

| Materials | Focus on engineering-grade powders (PA‑11, PA‑12, TPU, PP, etc.). | Wide variety of filaments (ABS, PLA, blends, specialty materials). |

| Throughput | High throughput for nested production builds. | Moderate throughput; speed depends heavily on part size and infill. |

| Ideal users | Manufacturers needing repeatable production and advanced design freedom. | Teams needing low-cost prototypes or very large-format parts. |

Both technologies can complement each other; many organizations use FDM for early mockups and MJF for validation prototypes and production parts.

To get the best engineering and business results from HP MJF, consider both technical setup and user experience.

- Design for MJF:

- Optimize wall thickness, fillets, and lattice structures to balance strength and build time.

- Take advantage of self-supporting powder to consolidate assemblies into fewer parts.

- Validate early:

- Print small pilot batches to confirm tolerances, fit, and surface finish before scaling.

- Document process parameters for each material and application.

- Plan capacity:

- Use the known build volume (380 x 284 x 380 mm) and build speed to model weekly output.

- Factor in cooling and post-processing time when quoting lead times.

If your team needs fast, repeatable, and production-grade plastic parts, HP Multi Jet Fusion offers a powerful path from concept to finished product. With its combination of speed, material performance, and design freedom, it can significantly reduce lead times and total product cost for the right applications.

- Ready to explore whether MJF is the right fit for your project?

- Need guidance on material selection, design rules, or cost modeling?

Contact us to get more information!

HP MJF 5600 printers provide a 1200 dpi resolution in the X and Y axes, enabling fine details and accurate geometries for both prototypes and end-use parts.

The effective build volume for HP MJF systems such as the 5600 series is 380 x 284 x 380 mm (15 x 11.2 x 15 in), which supports larger components or tightly nested arrays of smaller parts.

With build speeds of up to 3,466 cm³/hr (211 in⊃3;/hr), HP MJF is significantly faster than many traditional polymer 3D printing processes, especially when builds are densely packed.

Industries such as automotive, industrial automation, consumer products, and medical tooling use MJF for functional prototypes, jigs, fixtures, and end-use components that demand reliable mechanical performance.

Typical post-processing includes cooling, depowdering, bead blasting or tumbling, optional vapor smoothing, coloring (dyeing/painting), and sometimes thermal treatment like annealing to improve mechanical properties and aesthetics.