From 1 piece to mass production, our one-stop custom services ensure a worry-free experience for you.

Help Center

Views: 222 Author: Loretta Publish Time: 2025-12-23 Origin: Site

Content Menu

● What Is a Burr in Machining?

● Why Machining Burrs Matter for OEM Projects

● Main Types of Machining Burrs

>> Common Burr Types and Where They Occur

● Root Causes of Burr Formation

● Effects of Burrs on Different Materials

● Traditional Burr Removal Methods

● Advanced and Automated Deburring Technologies

>> Cryogenic Deburring for Plastics and Elastomers

>> Robotic and CNC-Integrated Deburring

● Burr Control in Metal Stamping

● Preventing Burrs at the Source

● Practical Burr Control Checklist for OEM Buyers

● Why Work With a Deburring-Focused OEM

● Start Your Next Burr-Controlled Project With U-NEED

● FAQs on Machining Burrs and Deburring

>> 1. What is a machining burr and why is it a problem?

>> 2. Are burrs completely unavoidable in CNC machining and stamping?

>> 3. Which deburring method is best for plastic and silicone parts?

>> 4. How do automated deburring systems improve consistency?

>> 5. What should be specified on drawings to control burrs?

Machining burrs may be small, but they have a big impact on safety, assembly quality, and overall production cost in precision manufacturing. For international OEM buyers and engineers working with Chinese suppliers like U-NEED, mastering burr prevention and deburring methods is essential to getting reliable, assembly-ready parts.

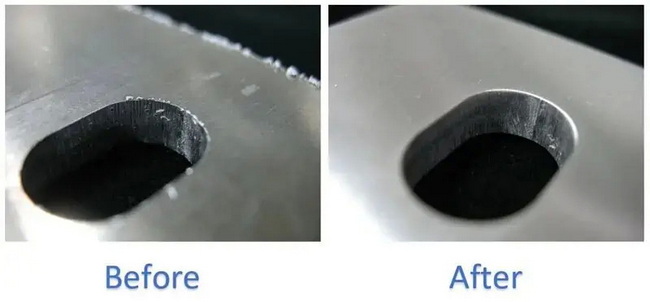

In machining, a burr is an unwanted ridge, flap, or sharp edge of material that remains attached to a part after cutting, drilling, milling, turning, stamping, or laser processing. Burrs usually appear where the tool exits the material, such as hole edges, slots, parting lines, or sheared edges.

Even when dimensional tolerances are met, burrs can still cause assembly failures, leaks, premature fatigue, and safety risks for operators and end users. For high-precision OEM projects, deburring is not just cosmetic; it is a critical quality and compliance step.

For global buyers working with outsourced machining and molding partners, burr control directly affects quality, cost, and brand reputation.

Key impacts include:

- Assembly problems – Burrs can block holes, misalign mating surfaces, and prevent proper sealing or fastening.

- Reduced fatigue life – Sharp edges act as stress concentrators, accelerating crack initiation in dynamic or high-pressure components.

- Safety and regulatory risk – Uncontrolled burrs can cut operators and violate safety or medical standards.

- Higher total cost – Extra manual deburring, rework, and scrap quickly erode any unit-price advantage.

Industries such as aerospace, automotive, medical devices, electronics, and fluid power often define burr specifications in drawings, standards, and customer quality agreements. Choosing an OEM that understands deburring is therefore as important as choosing one that understands tight tolerances.

Different machining processes create different burr geometries, and each requires specific removal strategies.

Burr type | Typical process / location | What is happening at the edge |

Poisson burr | Edge of milled or turned parts in ductile metals | Material is plastically pushed sideways instead of cut cleanly, forming a thin lip. |

Roll-over burr | Tool exit in milling, drilling, slotting | The tool bends material ahead of the cut, leaving a curled flap at the exit side. |

Breakout burr | Exit side of drilled holes | Material fractures as the drill breaks through, creating a jagged ring. |

Cut-off / parting burr | Lathe parting, sawing, stamping cut edges | Remaining material is left at the last contact zone between tool and part. |

Micro-burr | Precision machining, laser cutting, micro-milling | Very small burrs that still affect sealing, coatings, or micro-assemblies. |

Understanding which type of burr dominates on a part helps select the most cost-effective deburring method and set realistic edge-quality specifications.

Burr formation is rarely caused by a single factor; it usually reflects a combination of tool, material, process, and design choices.

Major causes include:

- Tool wear and wrong geometry – Dull tools smear material instead of cutting; incorrect rake and clearance angles promote burrs.

- Improper cutting parameters – Incorrect feeds, speeds, or depth of cut increase plastic deformation at the exit edge.

- Material behavior – Ductile metals and some plastics tend to form roll-over burrs, while brittle materials tend to chip or fracture.

- Workholding and vibration – Poor clamping allows micro-movements, worsening burr height at tool exits.

- Part design – Thin walls, unsupported edges, and closely spaced holes often become burr “hot spots”.

By refining both design and process parameters early in a project, it becomes easier to reduce burr formation instead of relying only on downstream deburring.

Because U-NEED works with metal machining, plastic parts, silicone products, and metal stamping, burr characteristics vary across material families.

- Metals (aluminum, steel, copper, brass) – Burrs can interfere with tight fit, cause stress risers, and damage sealing surfaces or coatings.

- Plastics – Burrs may be softer but can cause assembly misalignment, cosmetic defects, and contamination in fluid or medical systems.

- Silicone and elastomers – Gate vestiges and flash act like burrs, affecting sealing, comfort, and appearance in consumer or medical products.

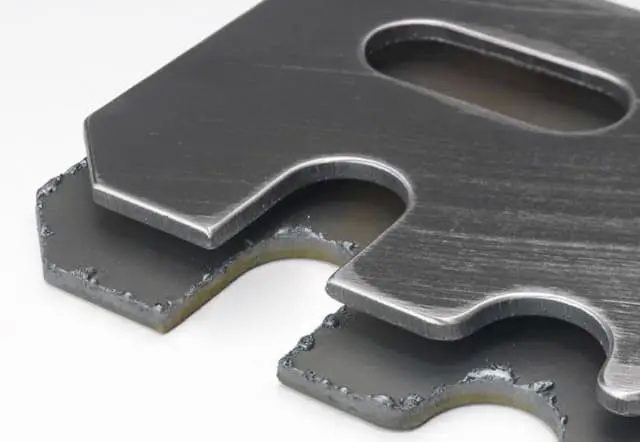

- Stamped metal parts – Stamping typically produces cut-off burrs and edge rollover that must be managed according to the “safe edge” or radius requirement.

Selecting the right deburring process for each material is key to keeping surfaces functional yet cost-effective.

Traditional deburring is still widely used, especially for small batches, prototypes, or complex one-off parts.

Manual deburring uses files, scrapers, knives, abrasive pads, or small rotary tools.

- Pros

- Very flexible; can reach complex features with skilled operators.

- Low initial investment for tools and fixtures.

- Cons

- Inconsistent quality between operators and across shifts.

- Labor-intensive and hard to scale for high-volume OEM production.

Mechanical methods include vibratory tumbling, barrel tumbling, and abrasive belts or wheels.

- Pros

- Efficient for bulk parts with similar size and geometry.

- Can improve both burr removal and overall surface finish.

- Cons

- Limited control on critical edges or tight-tolerance features.

- May require masking or fixturing to protect sensitive surfaces.

These traditional methods still have a place, but for demanding exports and high-mix production, more automated and specialized solutions increasingly dominate.

As labor costs rise and quality expectations tighten, many OEMs are adopting automated and specialized deburring processes.

Thermal deburring uses a combustible gas mixture ignited in a closed chamber to burn off fine burrs, especially in internal passages. It is suitable for complex manifolds, cross-drilled holes, and internal intersections, and it requires careful control to avoid surface damage.

Electrochemical deburring removes burrs using controlled anodic dissolution in an electrolyte under low voltage. It is excellent for hard-to-reach burrs on conductive materials with demanding tolerances and is common in automotive, hydraulic, and medical components.

Cryogenic deburring chills parts to very low temperatures, making burrs and flash brittle before tumbling or blasting them away with media. This method is very effective on plastic and silicone parts where burrs are flexible at room temperature and helps improve cosmetic consistency.

Robots or CNC machines equipped with compliant tools, brushes, or grinding heads can perform consistent deburring along programmed toolpaths. These systems offer high repeatability and are well suited to integration with in-line inspection, but they require stable fixturing and consistent incoming part quality.

A combination of manual, mechanical, and automated approaches can be selected according to volume, geometry, and specification to achieve the best balance of cost and quality.

For metal stamping, burrs and edge conditions are directly linked to tool wear, clearance, and material thickness.

Key points for stamped parts:

- Die clearance and sharpness strongly influence burr height and rollover.

- Edge rounding and oxide removal are often required for stamped or laser-cut parts used in structural or safety-related applications.

- Automated deburring and edge-rounding machines can simultaneously remove burrs, radius edges, and clean oxides on both sides of the strip or sheet in a single pass.

Clear edge-quality requirements, such as maximum burr height or minimum edge radius, should be communicated in drawings and RFQs to ensure alignment with suppliers.

Preventing burrs is often cheaper and more robust than relying solely on downstream deburring.

Key prevention strategies include:

1. Optimized tool selection and maintenance

- Use sharp tools with appropriate geometry for each material.

- Implement tool-life monitoring and scheduled replacement.

2. Refined cutting parameters

- Adjust feeds and speeds to minimize plastic deformation at tool exit.

- Use proper step-over and depth of cut to avoid excessive cutting forces.

3. Robust fixturing and workholding

- Rigid, vibration-free setups generate cleaner edges.

- Avoid overhangs or unsupported thin features where possible.

4. Smart part design for deburring

- Add chamfers or break edges on critical features to control the final edge condition.

- Space holes and slots to allow tool access for deburring brushes or media.

Joint design-for-manufacturing reviews with suppliers can significantly reduce burr formation before the first part is produced.

When sourcing from an external supplier, the following checklist helps align expectations and avoid surprises:

1. Define edge requirements clearly

- Specify allowed burr height, edge radius, or “sharp but not cutting” where applicable.

2. Match deburring method to application

- High-pressure hydraulics or medical devices may require advanced deburring such as electrochemical or thermal methods.

3. Ask for process documentation

- Request descriptions of deburring steps, inspection methods, and sampling plans.

4. Review sample parts

- Inspect edges under magnification and in realistic assembly conditions.

5. Plan for scalability

- Ensure the deburring approach used for prototypes can scale to full production volumes.

This structured approach makes burr control a predictable, managed part of the supply chain rather than a recurring problem.

International buyers increasingly expect parts to arrive ready to assemble, not just roughly machined or stamped. By integrating deburring into machining, plastic processing, silicone molding, and stamping, a deburring-focused OEM can:

- Deliver consistent edge quality for high-precision mechanical parts, plastic components, silicone products, and stamped metal components.

- Combine manual, mechanical, and automated deburring methods according to part geometry and industry requirements.

- Help customers reduce in-house rework, safety risks, and warranty claims by providing burr-controlled components from the start.

This capability is especially valuable for foreign brand owners, wholesalers, and manufacturers seeking reliable long-term OEM partners in China.

If burr issues are slowing your production, extending assembly time, or triggering quality complaints, it is time to cooperate with a supplier that treats edge quality as a core part of the process. Send your drawings and 3D models to U-NEED, indicate your critical edge requirements and application scenarios, and request a detailed quotation with a clear deburring plan. Take the next step now and launch your next CNC machining, plastic, silicone, or metal stamping project with U-NEED so your parts arrive clean, safe, and truly ready to assemble.

A machining burr is a small ridge or flap of material left on a part after a cutting, drilling, or stamping operation, and it can cause assembly issues, leaks, and safety risks if not removed.

Burrs cannot be eliminated entirely, but they can be greatly reduced through optimized tooling, parameters, and part design, and then controlled with suitable deburring methods for the remaining edges.

For plastic and elastomer components, cryogenic deburring and specialized media processes are often preferred, because they cleanly remove soft burrs and flash without damaging the base material or altering critical dimensions.

Automated systems such as robotic or CNC-based deburring use programmed paths and compliant tools to apply uniform pressure and motion, resulting in repeatable edge quality and reduced dependence on manual skill.

Drawings should define maximum burr height, edge radius or chamfer requirements, critical “no burr allowed” zones, and any relevant industry standards so that OEM suppliers can design appropriate deburring and inspection processes.