From 1 piece to mass production, our one-stop custom services ensure a worry-free experience for you.

Help Center

Views: 222 Author: Rebecca Publish Time: 2026-02-20 Origin: Site

Content Menu

● What Are Metal Casting Defects?

● Why Metal Casting Defects Matter for Your Business

● Main Types of Metal Casting Defects and Their Causes

>> 2. Shrinkage Cavities and Sponge Areas

>> 5. Inclusions and Sand Defects

>> 6. Mold Shift and Dimensional Inaccuracies

● How to Diagnose Defects in Metal Casting

● Practical Remedies for Common Casting Defects

>> Short‑Term Fixes at Process Level

>> Long‑Term Prevention Strategy

● Steel Casting Defects and Remedies

● Pouring Metal Defects in Casting: How to Prevent Them

● Limitations of Metal Casting: When You Should Rethink Your Process

● How CNC Machining Helps Salvage and Upgrade Castings

● Best Practices to Reduce Casting Defects in Modern Foundries

● Typical Metal Casting Defects and Remedies (Quick Reference)

● When to Choose CNC Machining Instead of Casting

● Clear, Targeted Call to Action

● FAQs About Metal Casting Defects

>> 1. What is the most common metal casting defect?

>> 2. How do I know if a defective casting can be salvaged?

>> 3. Are casting simulation tools worth the cost?

>> 4. Does heat treatment help with casting defects?

>> 5. How often should foundries review their casting process parameters?

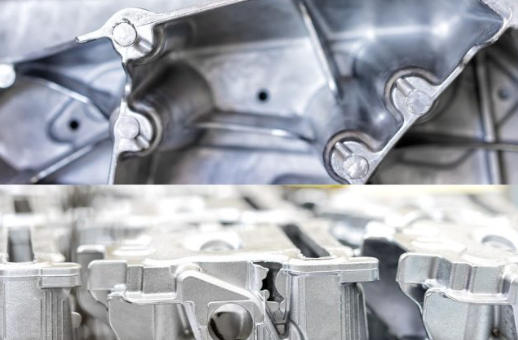

Metal casting defects are one of the fastest ways to lose money, delay shipments, and damage your brand reputation. When you understand the types of metal casting defects, their root causes, and practical remedies, you can dramatically cut scrap rates and keep your foundry or supply chain under control. This guide also explains how CNC machining and EDM post‑processing can turn borderline castings into high‑value, in‑tolerance parts instead of scrap.

A casting defect is any irregularity that makes the cast part deviate from its intended shape, size, surface quality, or mechanical performance. Defects may be clearly visible on the surface or completely hidden inside the metal, appearing at different stages such as pouring, solidification, cooling, or shake‑out.

Common metal casting defects include:

- Gas porosity (blowholes, pinholes, micro‑porosity)

- Shrinkage cavities and sponge‑like regions

- Cold shuts and misruns

- Hot tears and cracks

- Inclusions (slag, oxides, sand)

- Mold shift and dimensional inaccuracies

These issues not only impact aesthetic quality but can critically weaken parts used in automotive, industrial, or structural applications.

Defects in metal casting directly affect cost, lead time, and downstream processing. Even minor defects may require rework, extra machining, or complete remanufacture.

Key business impacts of casting defects:

- Higher scrap rates and material waste

- Increased rework and labor hours

- Delayed delivery schedules and customer dissatisfaction

- Risk of field failures and warranty claims

- Lower overall equipment effectiveness (OEE) in foundries

Many foundries now combine real‑time data monitoring with robust quality systems to reduce defect and rework rates and to keep processes stable over time.

In this section, the major types of casting defects are grouped by their physical nature, with typical root causes for each.

What it is:

Gas porosity appears as rounded pores, blowholes, or tiny pinholes either on the surface or inside the casting.

Typical causes:

- Entrapped air or gas during pouring

- Gas‑generating reactions between molten metal and mold or core binders

- Poor mold venting or blocked vents

- Excessive moisture in sand or coatings

- Too high pouring temperature causing gas solubility and subsequent release

Why it is dangerous:

Gas pockets reduce cross‑sectional area, lower fatigue life, and can trigger crack initiation under cyclic loads.

What it is:

Shrinkage defects are internal or external cavities formed when the metal solidifies and contracts but is not properly fed by risers or feeders.

Typical causes:

- Inadequate riser size, position, or feeding path

- Poor gating design leading to hot spots

- Large variations in section thickness

- Incorrect pouring temperature and solidification control

Why it is dangerous:

Shrinkage zones act as stress concentrators and can cause failure in pressure‑bearing or structural components.

What they are:

A cold shut is a visible line where two metal fronts meet but do not fuse properly, while a misrun is an area where the cavity is not fully filled.

Typical causes:

- Low pouring temperature

- Slow mold filling or poor gating layout

- Excessive turbulence leading to premature cooling

- Narrow sections or long, thin flow paths

These defects reduce mechanical strength and are critical in thin‑walled, high‑load components.

What they are:

Hot tears are irregular cracks formed during solidification when the casting cannot freely contract. Cold cracks may appear later during cooling or during service.

Typical causes:

- Restrained thermal contraction due to rigid mold design

- Sharp internal corners and poor fillet design

- Uneven cooling rates and steep thermal gradients

- Alloys with wide solidification ranges and high hot‑strength

Hot tearing is especially common in steel castings because of the high melting temperature and large thermal stresses.

What they are:

Inclusions are non‑metallic particles such as slag, oxides, sand, or refractory fragments trapped in the casting.

Typical causes:

- Poor melt cleanliness or inadequate slag removal

- Eroded mold or core materials entering the stream

- Turbulent flow causing coating or core fragments to detach

- Lack of filters or strainer cores in gating systems

Inclusions often initiate fatigue cracks and severely reduce surface finish quality.

What it is:

Mold shift occurs when cope and drag are misaligned, resulting in a step or offset in the casting.

Typical causes:

- Poor mold clamping or inadequate flask rigidity

- Worn patterns or locating pins

- Vibration or handling errors before or during pouring

Even a small shift can push parts out of tolerance, especially in precision machined interfaces.

Accurate diagnosis is the first step in selecting the right remedy or deciding whether a part can be salvaged by machining.

Common inspection methods:

- Visual inspection for surface cracks, cold shuts, misruns, and roughness

- X‑ray radiography for internal porosity and shrinkage cavities

- Ultrasonic testing for internal cracks, laminations, and bonding issues

- Dye penetrant testing for surface‑breaking cracks and hot tears

- Dimensional checks with CMMs for mold shift, warpage, and tolerance deviations

Combining these methods helps separate superficial cosmetic issues from critical structural defects and supports robust decisions about rework or scrap.

Once the root cause is known, foundries can apply targeted short‑term fixes and long‑term prevention strategies.

- Adjust pouring temperature and speed to improve flow and reduce turbulence.

- Modify gating and riser design to avoid hot spots and improve feeding.

- Improve mold venting and reduce moisture in sand systems.

- Use better raw materials, fluxes, and filtering media to reduce inclusions.

These changes can quickly cut the most obvious defects but should always be verified with ongoing inspection.

- Implement in‑process inspection for melt temperature, sand properties, and mold integrity.

- Use simulation software to optimize gating, risers, and solidification patterns.

- Standardize work instructions and operator training for pouring and mold handling.

- Combine casting with post‑casting CNC machining and EDM to consistently meet tight tolerances.

A structured prevention approach reduces defect trends over time and stabilizes overall product quality.

Steel castings are particularly prone to shrinkage, hot tears, and cracking due to high melting temperatures and narrow process windows.

Common steel casting defects:

- Centerline shrinkage in thick sections

- Hot tears near sharp corners or constrained zones

- Gas porosity from improper deoxidation

- Surface cracks caused by rapid cooling

Typical remedies and good practices:

- Use high‑quality refractory materials with good thermal shock resistance.

- Carefully control pouring and mold temperatures to avoid thermal shock.

- Optimize section transitions and fillets to reduce stress concentration.

- Apply post‑casting CNC machining to correct dimensional issues and remove surface‑connected defects.

Pouring is one of the most sensitive stages in the entire casting process. Small errors here can trigger multiple defect mechanisms at once.

Typical pouring‑related defects:

- Turbulence‑related air entrapment causing porosity

- Mold erosion leading to sand and coating inclusions

- Temperature inconsistencies generating cold shuts and misruns

Pouring best practices:

- Use controlled pouring systems such as bottom pouring, ladle lips, or pouring basins.

- Maintain stable melt temperature within the recommended range for each alloy.

- Ensure the mold has adequate rigidity and erosion resistance.

- Minimize pouring height to reduce turbulence and air aspiration.

Metal casting is not inherently unsafe, but it involves significant risks if best practices are not followed.

Typical safety risks include:

- Severe burns from molten metal and hot equipment

- Exposure to toxic fumes from binders, coatings, or certain alloys

- Crushed‑hand or ergonomic injuries from heavy tools and molds

- Fire hazards from combustible materials and splashes

Modern foundries mitigate these risks through personal protective equipment, engineering controls, fume extraction, and strict operating procedures. For high‑precision prototypes or small batches, many customers choose CNC machining to reduce the complexity and risk associated with foundry operations.

Metal casting is ideal for high‑volume production of complex metal shapes, but it is not always the best solution for every project.

Typical disadvantages of metal casting:

- Relatively high defect rates compared with fully machined parts

- Long lead times for patterns, cores, and tooling

- Need for extensive post‑processing such as grinding, machining, and heat treatment

- Variability in mechanical properties because of porosity and microstructure differences

For safety‑critical or extremely tight‑tolerance components, combining casting with precision CNC machining and EDM offers a more reliable route to final dimensions and performance.

In many cases, casting defects do not mean the part must be scrapped. With the right CNC machining strategy, foundries and OEMs can recover value and keep projects on schedule.

Typical ways CNC machining adds value to castings:

- Correcting dimensional inaccuracies from mold shift or warpage

- Machining away surface‑connected porosity and shallow defects

- Creating precise mating surfaces, threads, and bores

- Achieving high‑quality surface finishes for sealing, sliding, or cosmetic areas

When combined with methods such as EDM wire cutting and EDM hole drilling, even complex inner geometries or hardened zones can be refined to specification. For brands and manufacturers who rely on overseas foundries, partnering with a dedicated CNC machining supplier creates an extra quality barrier between the foundry and the final assembly line.

Leading foundries and OEMs use a combination of process control, data, and design optimization to stay ahead of casting defects.

Foundry best practices:

1. Maintain consistent sand quality in terms of moisture, permeability, and strength.

2. Standardize melt treatment, including degassing, grain refinement, and deoxidation.

3. Use gating and riser simulation tools before freezing any new tooling.

4. Implement real‑time data collection on temperature, metal chemistry, and cooling behavior.

5. Establish closed‑loop feedback between casting inspection and process engineering.

By following these practices, manufacturers can significantly reduce defects and rework, improving both competitiveness and margins.

| Defect type | Main symptoms | Typical causes | Practical remedies |

|---|---|---|---|

| Gas porosity | Rounded holes, pinholes inside part | Poor venting, moisture, high pouring temperature | Improve venting, degas metal, control moisture |

| Shrinkage cavities | Internal voids, sponge‑like regions | Inadequate feeding, hot spots | Optimize risers, modify gating, use chills |

| Cold shuts / misruns | Visible seams, incomplete filling | Low temperature, slow fill, thin sections | Raise temperature, redesign gating, shorten flow path |

| Hot tears and cracks | Irregular cracks, often at corners | Restrained contraction, uneven cooling | Redesign fillets, control cooling, use flexible molds |

| Inclusions / sand | Hard spots, slag pockets, rough areas | Mold erosion, dirty melt, turbulence | Improve melt cleaning, add filters, stabilize pouring |

| Mold shift | Offset surfaces, step at parting line | Poor clamping, worn patterns, vibration | Improve fixturing, repair patterns, review handling |

For some projects, it is more efficient to skip casting entirely and go directly to CNC machining from solid bar, billet, or plate.

CNC machining is usually a better choice when:

- You need small or medium volumes with frequent design changes

- The part requires very tight tolerances and consistent properties

- The geometry is not extremely material‑intensive

- You cannot accept variability in porosity or internal structure

Many companies now use a hybrid strategy: casting for bulk near‑net shapes and precision CNC machining for critical surfaces and interfaces.

If you are facing recurring metal casting defects, you do not have to accept high scrap rates, unstable lead times, or constant rework. By combining smarter process control with high‑precision CNC machining, EDM wire cutting, and EDM hole drilling, you can stabilize quality and protect your delivery commitments. Share your drawings, tolerance requirements, and target quantities, and let our engineering team evaluate whether your existing castings can be optimized, salvaged, or replaced with a more robust machining‑based solution tailored to your application.

Contact us to get more information!

Gas porosity and shrinkage cavities are among the most frequently observed metal casting defects. They appear in many alloys and processes, especially in complex or thick‑section castings where feeding and venting are more challenging.

A casting is usually salvageable if defects are limited to non‑critical regions or can be removed by machining without undermining strength or function. Detailed inspection, combined with an engineering review of the drawing, will show whether CNC machining or EDM can remove the affected zones while keeping the part within specification.

For recurring production or complex parts, casting simulation tools often pay for themselves by reducing trial‑and‑error in tooling and process setup. They help optimize gating, risers, and solidification patterns, lowering the risk of porosity, shrinkage, and hot tears before full production starts.

Heat treatment can improve microstructure, relieve residual stress, and enhance mechanical properties, but it cannot remove porosity or shrinkage cavities. Those internal volume defects must be addressed through process changes, better feeding, or by removing affected material through machining.

High‑performing foundries monitor critical parameters continuously and review process windows whenever defect trends change, materials are updated, or new products are introduced. A regular review schedule, combined with statistical analysis of defect data, helps keep the process under control and prevents quality drift.