From 1 piece to mass production, our one-stop custom services ensure a worry-free experience for you.

Help Center

Views: 222 Author: Rebecca Publish Time: 2025-12-31 Origin: Site

Content Menu

● What Is Plastic CNC Machining[2]

● How Plastic Differs From Metal CNC Machining[3]

● Achievable Tolerances in Plastic CNC Machining[9]

● Choosing the Right Plastic for CNC Machining[1]

>> Common CNC Plastics and Best Uses[2]

● Cutting Tools and Geometry for Plastics[3]

● Feeds, Speeds, and Cooling Strategies[3]

● Avoiding Melting, Burrs, and Static[8]

● CNC Plastic Machining vs Injection Molding in 2026[12]

● Key Application Areas for CNC Machined Plastics[1]

● Practical Design Tips for CNC Plastic Parts[1]

● How a Professional OEM Partner Adds Value[15]

● FAQs About CNC Machining Plastic Parts

>> Q1. How accurate can CNC plastic machining be[9]

>> Q2. Which plastic is best for precision gears and bushings[2]

>> Q3. Can clear plastics like acrylic and polycarbonate be CNC machined without losing transparency[2]

>> Q4. When is CNC machining cheaper than injection molding[12]

>> Q5. How can warping in plastic CNC parts be reduced[9]

Plastic CNC machining has become a core process for lightweight, high-precision parts in sectors such as medical, automotive, aerospace, and electronics. The real advantage appears when you combine the right plastic material, optimized cutting strategies, and a reliable OEM partner that understands tolerance control and production economics.[2][4][1]

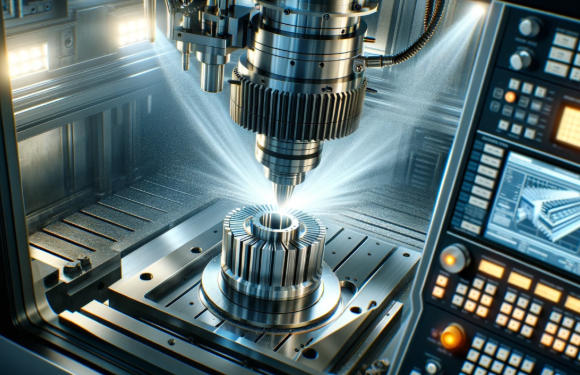

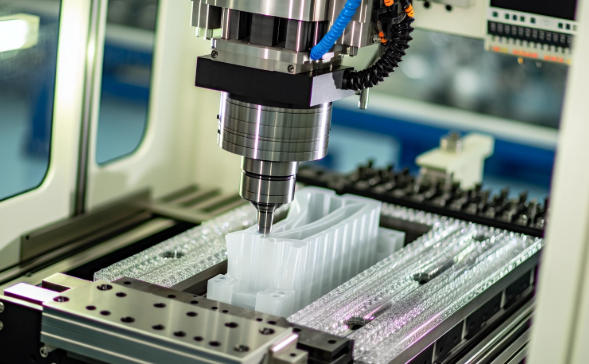

Plastic CNC machining is the subtractive manufacturing of plastic stock into precise components using computer-controlled mills, lathes, and routers. Compared with additive methods, it can achieve tighter tolerances, smoother surfaces, and supports a much wider choice of engineering plastics.[4][2]

Plastic CNC machining is especially suitable when you need:

- Tight dimensional control on functional features, such as sealing grooves, bearing seats, or sliding elements.[5][4]

- Stable quality from prototype to low–medium volume production with repeatable setups.[6][1]

- Materials that are difficult or uneconomical to injection mold at low volumes, including specialty or filled grades.[7][6]

Although the machines look similar, plastics do not behave like metals under the cutter. Understanding these differences is essential for avoiding melting, warping, or out-of-tolerance parts.[8][3]

Key differences include:

- Heat sensitivity: Plastics have lower melting points and lower thermal conductivity, so heat builds up quickly at the cutting edge.[3][8]

- Elasticity and deflection: Many plastics are softer and more elastic, which can cause the workpiece to deflect under cutting forces and spring back when the tool exits.[8]

- Thermal expansion: Plastics expand and contract more with temperature changes, so tolerances must consider machining temperature and part geometry.[9][5]

Modern machining processes can deliver high accuracy on plastics when material stability, geometry, and process control are all considered. Typical tolerance capability depends on the application and the plastic chosen.[4][5][9]

Common tolerance ranges:

- Standard commercial plastic parts often hold around ±0.10 mm to ±0.25 mm on non-critical dimensions.[4]

- Precision plastic components can reach better than ±0.05 mm, and certain high-performance materials such as PEEK or POM can achieve ±0.01 mm on critical features under controlled conditions.[5][9]

Useful practices include:

- Selecting dimensionally stable materials (for example, POM or PEEK) for tight-tolerance features.[5][9]

- Using staged machining with roughing, stress relief, and finishing steps for thick or heavily stressed parts.[8][9]

Material selection directly influences tolerances, surface quality, machining time, and long-term part performance. Matching material properties to the operating environment and functional requirements is essential for reliable parts.[10][1]

| Plastic | Key properties | Typical applications |

|---|---|---|

| ABS | Tough, impact resistant, easy to machine. | Housings, enclosures, fixtures, consumer product prototypes. |

| FR4 | Rigid, heat resistant, excellent electrical insulation. | Circuit boards, electronic fixtures, insulating plates. |

| Nylon (PA) | High wear resistance, self‑lubricating, good toughness. | Gears, bushings, sliding components. |

| Polycarbonate (PC) | Very tough, transparent grades, good impact strength. | Machine guards, safety lenses, transparent covers. |

| PMMA (Acrylic) | High clarity, good surface polish, relatively hard. | Displays, light diffusers, clear prototypes. |

| POM (Acetal) | Excellent dimensional stability, low friction, good machinability. | Precision gears, valve components, motion mechanisms. |

| PTFE | Very low friction, outstanding chemical resistance. | Seals, gaskets, chemical handling parts. |

| PEEK | High temperature, high strength, excellent chemical resistance. | Aerospace, medical, high‑load mechanical parts. |

Selection hints:

- For toughness and impact resistance, ABS or PC is often suitable.[10][2]

- For low friction and sliding wear, nylon or POM is frequently used.[2][5]

- For transparency or optical evaluation, PMMA or clear PC are common.[2]

- For aggressive chemical or high-temperature environments, PTFE or PEEK is often preferred.[9][10]

Tooling strongly affects edge quality, surface finish, and cycle time when machining plastics. Proper choice of tool material and flute geometry helps avoid heat buildup and poor chip evacuation.[3][8]

Key points:

- Solid carbide cutters typically provide better wear resistance and sharper edges than HSS tools, which is important for brittle or clear plastics.[3]

- Single-flute or two-flute designs offer larger chip spaces and lower heat generation than multi-flute tools.[8][3]

- O-flute cutters are widely used for acrylic and other clear plastics to produce clean, almost polished edges.[3]

Plastics require enough surface speed to cut cleanly but not so much that heat causes melting or dimensional drift. Achieving this balance requires attention to tool condition, feed rates, and chip evacuation.[8][3]

Important guidelines:

- Sharp tools, moderate spindle speeds, and relatively higher feed rates help remove chips quickly and reduce rubbing.[3]

- Air blast cooling is often effective because it cools the cutting zone and clears chips without introducing incompatible coolants.[8][3]

- Minimal-quantity lubrication or mist can assist in specific materials, but chemical compatibility must be confirmed to avoid stress cracking.[8]

For drilling, peck cycles and polished drills with suitable point geometry reduce heat, clogging, and breakout in brittle plastics.[8][3]

Several recurring challenges in plastic machining can be controlled with proper tooling and process parameters. Paying attention to heat, chip removal, and static management leads to more consistent results.[11][3][8]

Common issues:

- Melting and deformation often arise from excessive spindle speed, dull tools, and low feed rates that cause rubbing instead of cutting.[3]

- Burrs and frayed edges are frequently caused by worn tools, inadequate rake angle, or inappropriate toolpaths.[11][8]

- Static buildup and chip cling, especially on acrylic and polycarbonate, may require antistatic sprays, ionized air, and effective dust extraction.[8]

Choosing between CNC plastic machining and injection molding depends on volume, design maturity, and performance targets. Each method has a distinct cost and flexibility profile.[13][6][7][12]

Typical selection logic:

- CNC machining is advantageous for prototypes and low–medium volumes where tooling cost would be difficult to amortize and design changes are expected.[6][7][12]

- Injection molding becomes attractive for high-volume production where unit cost must be minimized and the design is stable.[13][6]

Many manufacturers in 2026 use CNC machining for early validation and market launch, then invest in molds once demand and design are confirmed.[14][12][6]

High-precision plastic components continue to gain market share as industries seek lighter, corrosion-resistant alternatives to metals. CNC machining supports complex geometries and small batches across multiple sectors.[10][1]

Typical sectors:

- Medical and life sciences, including prosthetic elements, diagnostic fixtures, and transparent housings.[10][2]

- Consumer electronics and appliances, including internal structures, mounting frames, and enclosure details in ABS, PC, and FR4.[10][2]

- Automotive and aerospace, including interior components, gears, bushings, and weight-optimized brackets.[1][10]

- Industrial automation and robotics, including guides, wear strips, custom gripping jaws, and insulating components.[1][10]

Good design improves machinability, stability, and cost control for plastic parts. Early consideration of geometry and tolerances can prevent problems later.[5][10][1][8]

Design recommendations:

- Limit very tight tolerances to truly critical features and use looser tolerances elsewhere to reduce cost and risk of scrap.[4][5]

- Use generous fillet radii in internal corners to reduce stress concentration and allow the use of larger, more rigid tools.[1][8]

- Aim for uniform wall thickness where possible to reduce warping and residual stress.[8]

- Provide reference surfaces or clamping zones that support secure fixturing during machining.[8]

Working with a machining specialist helps transform drawings into repeatable plastic components while controlling cost and lead time. Coordinated engineering support also reduces the risk of failures in the field.[15][11][10][1]

Benefits typically include:

- Application-driven material selection aligned with mechanical, chemical, and regulatory requirements rather than generic choices.[10][1]

- Proven process windows for different plastics and geometries, improving consistency and reducing trial-and-error on the production floor.[11][3]

- Integrated handling of plastic machining alongside metal machining and stamping, which simplifies supply chains for OEM customers.[15]

By combining these strengths, an experienced partner can support both early prototypes and scalable series production across multiple material families.[15][10]

If you are planning a project that involves high-precision plastic components together with metal or silicone parts, share your drawings, expected quantities, and performance targets to receive an engineering-level manufacturability review and a customized quotation tailored to your application.

For many engineering plastics, tolerances around ±0.05 mm are realistic on well-designed parts with controlled machining conditions. With dimensionally stable materials such as PEEK or POM and a controlled environment, critical dimensions can reach ±0.01 mm.[4][5][9]

POM and nylon are commonly used for gears and bushings because they combine low friction with good wear resistance and load capacity. POM offers particularly strong dimensional stability, which helps maintain tooth geometry and bearing fits over time.[5][2][10]

Clear plastics can maintain high transparency when machined with sharp tools, appropriate feeds and speeds, and effective chip evacuation. O-flute tools and controlled cutting conditions help achieve very smooth surfaces that often require minimal post-polishing.[2][3][8]

CNC machining is usually more economical for prototypes and low–medium volumes where tooling cost cannot be spread over many parts. It is also attractive when frequent design changes are expected or when specialty materials and small batches are required.[7][6][12][13]

Warping can be reduced by choosing dimensionally stable materials, designing more uniform wall thicknesses, and using staged machining with stress relief between roughing and finishing. Controlled heat input and robust fixturing further improve stability on sensitive geometries.[5][9][8]

[1](https://www.facturee.de/en/material-for-cnc-machining-a-comprehensive-guide/)

[2](https://www.fictiv.com/articles/cnc-plastics-selection-guide)

[3](https://www.cnccookbook.com/cnc-machining-plastics/)

[4](https://prime-metals.com/cnc-plastic-parts-tolerances-complete-engineers-guide-charts-included/)

[5](https://www.newaymachining.com/blogs/cnc-milling-plastics-what-buyers-should-know-about-tolerances-warping-and-surface-finish)

[6](https://gree-ge.com/cnc-machining-vs-injection-molding-top-10-insights-for-manufacturers/)

[7](https://www.linkedin.com/pulse/plastic-cnc-vs-injection-molding-which-method-better-you-angela-chen-rrioc)

[8](https://www.mcam.com/dam/jcr:7a0e118b-f524-452b-98fa-35c0a3340687/MCG-Machinist-Toolkit-A4-rgb-stg-Dec22.pdf)

[9](https://aipprecision.com/engineering-success-critical-tolerances-for-dimensionally-stable-plastic-parts/)

[10](https://www.atlasfibre.com/expert-guide-to-choosing-the-best-materials-for-machined-plastic-parts/)

[11](https://at-machining.com/the-best-practices-for-plastic-cnc-machining-precision-and-efficiency/)

[12](https://www.chencancnc.com/news/cnc-vs-injection-molding-which-is-better-for-making-molds-in-2026/)

[13](https://www.fictiv.com/articles/injection-molding-trends-2026)

[14](https://www.topstarmachine.com/injection-molding-trends-in-2026-ai-and-smart-production-workflows/)

[15](https://www.lsrpf.com/blog/the-ultimate-guide-to-cnc-machining-materials-optimizing-processes-for-metals-and-plastics)

content is empty!