From 1 piece to mass production, our one-stop custom services ensure a worry-free experience for you.

Help Center

Views: 222 Author: Loretta Publish Time: 2025-12-24 Origin: Site

Content Menu

● What Makes a Top CNC Machining Manufacturer

● 1. U-Need Precision Machinery Co., Ltd. (Dongguan)

>> Main services and processes

>> Engineering strength and project management

>> Quality assurance and inspection

>> Global reach and supply-chain resources

● 2. Shenyang Machine Tool Co., Ltd. (SMTCL)

● 3. Qinchuan Machine Tool & Tool Group

● 4. Neway CNC Equipment (Suzhou) Co., Ltd.

● 5. 3ERP

● 6. DEK

● How to Choose Among Chinese CNC Machining Manufacturers

>> Clarify technical and business requirements

>> Screen and compare candidate manufacturers

>> Evaluate quality systems and communication

>> Start with prototypes or pilot orders

● Why U-Need Is a Strong First Choice

● FAQ

>> 1. What information should be provided when contacting CNC Machining Manufacturers in China?

>> 2. How can I verify the quality level of a new CNC machining supplier like U-Need?

>> 3. Why is a one-stop OEM partner better than using multiple separate CNC Machining Manufacturers?

>> 4. Are Chinese CNC Machining Manufacturers suitable for both high-mix and low-volume orders?

>> 5. How does location in China affect the choice of CNC Machining Manufacturers?

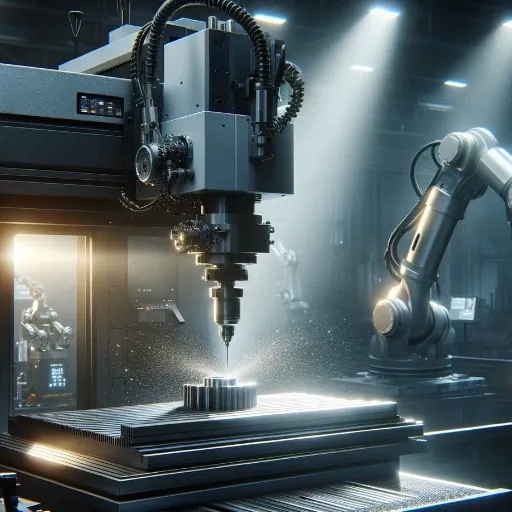

China has become one of the most competitive bases in the world for high-quality CNC Machining Manufacturers, supported by a mature industrial ecosystem, strong engineering talent, and cost-effective production. Overseas brands, wholesalers, and OEM producers increasingly rely on Chinese CNC Machining Manufacturers for precision parts made from metals, plastics, and silicone, as well as for metal stamping and integrated assemblies. For such buyers, choosing the right partner is crucial to achieve stable quality, on-time delivery, and attractive pricing.

When selecting CNC Machining Manufacturers in China, buyers should look beyond simple pricing and consider the full technical and service capability. A top manufacturer not only owns advanced equipment but also understands engineering design, process optimization, quality assurance, and international logistics.

Key evaluation points include:

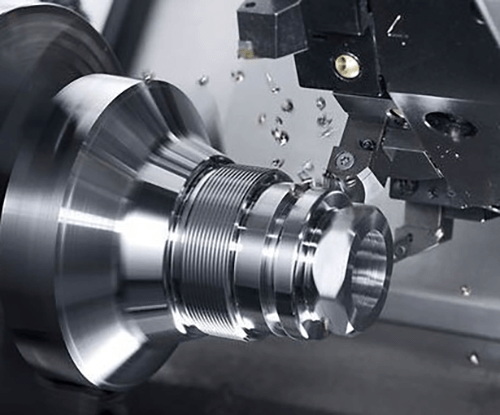

- Precision and stability: Ability to hold tight tolerances consistently, such as ±0.01 mm for general precision and down to ultra-precision ranges for critical components.

- Range of processes: CNC milling, CNC turning, grinding, EDM, wire EDM, plastic injection molding, silicone product molding, and metal stamping so that more of the product can be completed under one roof.

- Material capability: Support for aluminum, stainless steel, carbon steel, brass, copper, tool steel, engineering plastics (ABS, PC, POM, PEEK, etc.), and silicone elastomers.

- Quality system: Documented inspection flow, measurement equipment, and traceability, ensuring that every batch from CNC Machining Manufacturers can meet drawings and specifications.

- DFM and engineering support: Ability to review 3D and 2D files, provide design-for-manufacturing suggestions, and help customers optimize cost and performance.

- Export and communication experience: Familiarity with overseas standards and packaging requirements, plus fast, clear communication in English.

With these factors in mind, the following sections introduce ten notable CNC Machining Manufacturers in China, with U-Need Precision Machinery Co., Ltd. placed in the leading position for its one-stop OEM capabilities.

U-Need Precision Machinery Co., Ltd., based in Dongguan, Guangdong, is a professional OEM manufacturer specializing in high-precision mechanical machining parts, plastic product manufacturing, silicone product manufacturing, and metal stamping production. U-Need stands out among CNC Machining Manufacturers as a comprehensive, one-stop partner for overseas brands, wholesalers, and producers who require multi-process integration and strict quality control.

U-Need provides a complete chain of services starting from early engineering communication to final mass production and packaging. The company can work directly from customer drawings, 3D models, or samples, and then:

- Evaluate the design with DFM thinking to suggest improvements in structure, material, or tolerance.

- Develop custom molds for plastic and silicone products, as well as tooling for metal stamping when needed.

- Arrange CNC machining, CNC turning, EDM, and other processes for metallic parts and critical precision features.

- Integrate plastic, silicone, and stamped parts into assemblies according to customer requirements.

Because many CNC Machining Manufacturers only focus on metal machining, they often cannot offer this level of integrated OEM service across metals, plastics, and silicone components. U-Need's combined capability significantly reduces coordination time and risk for overseas buyers who prefer a single responsible supplier.

U-Need covers a wide range of manufacturing processes that address different industries and design needs. Core services include:

- CNC machining: Multi-axis CNC milling and CNC turning for complex geometries, precise fits, and functional surfaces that require tight tolerances and good surface finish.

- Grinding and EDM: Surface grinding, cylindrical grinding, EDM, and wire cutting for mold components, precision blocks, inserts, and other high-accuracy parts.

- Plastic products manufacturing: Custom plastic injection parts for enclosures, housings, brackets, gears, and functional plastic components across consumer and industrial projects.

- Silicone products manufacturing: Molding of silicone seals, gaskets, protective covers, keypads, and other soft components that work together with CNC machined metal or plastic parts.

- Metal stamping: Production of sheet metal parts such as brackets, shields, terminals, and structural plates, which can be combined with CNC machined components in assemblies.

This rich process portfolio allows U-Need to support the full product lifecycle, from prototypes and trial builds to stable mass production, and to act as a central hub among CNC Machining Manufacturers for complex projects.

U-Need emphasizes close engineering communication with overseas customers. The technical team can interpret 2D drawings and 3D CAD models, identify potential machining risks, and propose adjustment suggestions on tolerances, radii, wall thickness, and assembly features. This early-stage optimization is especially valuable for new product introductions and helps prevent costly changes in later phases.

Project management is handled with clear milestones and feedback loops. Customers can receive:

- Pre-production reviews and confirmation samples.

- Dimensional inspection reports for key dimensions.

- Progress updates during mold fabrication, machining, and trial runs.

Compared with many small CNC Machining Manufacturers that only “follow drawings” passively, U-Need positions itself as an engineering partner that supports product success.

To ensure consistent quality, U-Need implements a structured quality-control workflow from incoming materials to final shipment. Typical practices include:

- Material verification with certificates and identification marks.

- In-process inspection at critical machining steps, using calipers, micrometers, gauges, and specialized fixtures where necessary.

- Final inspection according to drawing requirements, including dimensional checks, thread gauges, and appearance criteria.

These systems enable U-Need to deliver high-precision components that satisfy demanding applications in automation, instrumentation, consumer electronics, and other fields where CNC Machining Manufacturers must maintain strict tolerances and repeatability.

U-Need serves overseas clients across many countries and regions, supporting both small-batch orders and long-term mass production. The company has built a strong local supply network that includes surface treatment vendors (anodizing, plating, painting), standard component suppliers, and packaging partners.

By coordinating these resources, U-Need can provide:

- Flexible minimum order quantities suitable for startups and new projects.

- Competitive lead times, especially for CNC machined prototypes and trial runs.

- Full-package OEM service that reduces the workload on buyers who need reliable CNC Machining Manufacturers in China.

Shenyang Machine Tool is a long-established enterprise and one of the best-known names in China's machine tool industry. Though primarily a builder of machine tools rather than a contract machining workshop, SMTCL plays a central role in the ecosystem that supports CNC Machining Manufacturers across the country.

Its product lines include CNC lathes, machining centers, and milling machines that are widely used in automotive, heavy machinery, and other industrial sectors. Many Chinese CNC Machining Manufacturers operate SMTCL equipment to perform stable, large-scale production for domestic and international customers.

Qinchuan focuses on high-end CNC machine tools and precision machining equipment, targeting applications in aerospace, energy, transportation, and defense. While Qinchuan also provides certain machining services, its main impact on CNC Machining Manufacturers lies in supplying advanced equipment capable of high accuracy and reliability.

Companies that use Qinchuan machines often seek higher-precision performance, improved rigidity, and better surface finishes than what entry-level systems can provide. As Chinese industry moves up the value chain, such high-end capacity becomes increasingly important for CNC Machining Manufacturers serving technologically demanding markets.

Neway CNC Equipment is a well-known manufacturer of CNC lathes and machining centers, with equipment deployed in many factories on both domestic and international markets. By providing stable and versatile machines, Neway supports CNC Machining Manufacturers in sectors such as general machinery, valves, pumps, and energy-related components.

Factories that rely on Neway equipment can produce medium and large-scale batches of parts requiring consistency and efficiency, making it attractive for customers who need long-term supply agreements and repeat orders.

3ERP is a service-oriented provider that focuses on rapid prototyping and low-volume manufacturing. Unlike pure machine builders, 3ERP operates as one of the modern CNC Machining Manufacturers that accept part drawings and models from global clients and then deliver finished components.

Its offerings typically include CNC machining, 3D printing, vacuum casting, and sometimes sheet-metal work. This makes 3ERP a suitable choice for product developers, design firms, and startups that need functional prototypes or pre-production units before committing to high-volume tooling.

DEK is another service provider that positions itself among the flexible CNC Machining Manufacturers in China. It offers precision CNC machining, injection molding, and various surface finishes aimed at international customers.

DEK's strengths generally lie in accommodating a wide range of quantities, from prototypes up to medium-volume production, and in supporting multiple industries such as electronics, industrial devices, automation, and consumer products. For buyers, DEK can serve as a versatile partner when they require both CNC machining and molding from a single source.

GENSUN, based in South China, is one of the contract CNC Machining Manufacturers that focus on export-oriented business. Its core capabilities include CNC milling, CNC turning, and precision machining of metals and plastics.

Served industries often include robotics, automation equipment, consumer electronics, and other sectors where precision parts are important for performance. International customers often consider GENSUN together with other Dongguan- and Shenzhen-based CNC Machining Manufacturers when they want suppliers in the Pearl River Delta region.

Superapid is oriented toward rapid manufacturing, supporting both CNC machining and other prototyping technologies. It serves overseas customers that require fast turnaround and small to moderate quantities, which is essential during product development cycles.

By combining CNC machining with processes such as casting or additive manufacturing, Superapid can deliver functional prototypes, test parts, and bridge-production batches. This places it among the CNC Machining Manufacturers that emphasize speed and flexibility more than very high-volume output.

Runsom Precision, operating in the Shenzhen region, is another export-focused CNC machining service company. It typically provides CNC milling, CNC turning, and custom component manufacturing for foreign buyers in Europe, North America, and other markets.

As one of many mid- to high-end CNC Machining Manufacturers in South China, Runsom emphasizes communication, stable quality, and manageable lead times. It is often evaluated by buyers who prefer Shenzhen's infrastructure and logistics advantages.

Tik Precision, located in Dongguan, is a younger but growing CNC machining service company focusing on precision components. It tends to serve customers who require tighter tolerances, fine machining details, and good surface finishes in metals and plastics.

Because of its flexible size and engineering resources, Tik Precision can adapt quickly to changing project requirements and is sometimes shortlisted alongside other emerging CNC Machining Manufacturers in the region.

With many options available, overseas buyers should adopt a structured approach when selecting CNC Machining Manufacturers in China. A systematic evaluation helps ensure that the chosen partner can meet technical requirements, budget constraints, and long-term cooperation goals.

Before approaching suppliers, buyers need to clearly define:

- Part function, critical dimensions, and tolerance ranges.

- Material type, hardness or temper, and any special properties such as corrosion resistance or high-temperature behavior.

- Required surface finish, coatings, or colors.

- Annual volume, batch size, and expected ramp-up plan.

- Need for additional services such as assembly, testing, packaging, or logistics support.

This clarity helps CNC Machining Manufacturers prepare accurate quotations and realistic lead times, and it allows them to provide meaningful DFM feedback.

Next, buyers should compile a shortlist of CNC Machining Manufacturers that appear suitable in terms of location, size, and service scope. For each candidate, consider:

- Years of experience and main export markets.

- Core processes available in-house versus outsourced.

- Sample project photos, process descriptions, or application cases.

- Responsiveness and clarity during initial email or message exchanges.

From there, a smaller group of potential suppliers can be selected for deeper technical discussions.

Quality and communication are decisive factors when dealing with CNC Machining Manufacturers far from the buyer's home country. Important checks include:

- Whether the supplier has a documented inspection process with clear records.

- Type of measuring equipment and whether they can provide inspection reports upon request.

- How quickly and precisely they answer questions about tolerances, materials, and processes.

- Their willingness to discuss design issues rather than simply saying “OK” to everything.

Suppliers like U-Need that offer engineering support, DFM suggestions, and transparent quality control often reduce risk significantly for overseas projects.

Even with strong initial impressions, it is wise to begin with:

- A small prototype run for each key part.

- A pilot batch that simulates real production but at limited volume.

These early orders allow buyers to observe how CNC Machining Manufacturers handle machining consistency, packaging, marking, and shipping. Any discovered issues can be solved before full-scale mass production begins.

Among the many CNC Machining Manufacturers in China, U-Need Precision Machinery Co., Ltd. is especially attractive for overseas brands, wholesalers, and OEM producers because it combines multiple advantages in one supplier.

Key highlights include:

- Integrated processes: Precision CNC machining, plastic products manufacturing, silicone products manufacturing, and metal stamping under one company for smoother supply-chain management.

- Strong engineering support: DFM reviews, mold design, and improvement suggestions that help reduce costs and avoid production problems.

- Flexible order quantities: Ability to support prototypes, low-volume batches, and large-scale production as projects grow.

- Focus on export projects: Experience working with international customers, understanding of their expectations, and ability to provide stable quality and lead times.

For overseas buyers looking for CNC Machining Manufacturers that can act as long-term OEM partners rather than simple job shops, U-Need provides a balanced combination of precision, breadth of services, and project management capability.

China's manufacturing landscape offers a rich selection of CNC Machining Manufacturers, ranging from major machine tool builders to agile, service-oriented precision machining companies. Buyers can leverage this ecosystem to source high-quality components at competitive costs, but success depends heavily on choosing partners with the right mix of technology, quality, and communication.

U-Need Precision Machinery Co., Ltd. stands out as a preferred first choice due to its one-stop OEM service model that integrates high-precision machining, plastic and silicone product manufacturing, and metal stamping. By working closely with such a comprehensive partner, overseas brands, wholesalers, and producers can simplify their supply chains, accelerate development cycles, and gain more control over quality and delivery.

At the same time, other notable CNC Machining Manufacturers in China provide valuable options for different project scales and technical requirements, from rapid prototyping to high-volume production. By clarifying needs, carefully screening suppliers, and starting with well-controlled trial orders, international buyers can build long-term, reliable cooperation with Chinese CNC Machining Manufacturers and fully benefit from the country's advanced industrial capabilities.

Buyers should prepare detailed 2D drawings and 3D models when possible, including all critical dimensions, tolerances, materials, and surface-treatment requirements. Clear quantity expectations, packaging standards, and any special inspection or testing needs should also be stated up front so that CNC Machining Manufacturers can give accurate quotations and realistic lead times.

The most reliable way is to start with small prototype or trial orders and request full inspection reports for key dimensions, along with photos of the finished parts. Evaluating part quality, consistency across pieces, packaging, and communication during this early stage provides a realistic picture of the supplier's capability and helps decide whether to scale cooperation with that CNC machining supplier.

A one-stop OEM partner can coordinate machining, molding, stamping, and finishing processes internally, which reduces handover risks, saves time, and simplifies communication. Instead of managing several different CNC Machining Manufacturers for metals, plastics, and silicone parts, buyers can rely on a single project team that understands the entire product and can optimize cost, assembly fit, and overall performance.

Many Chinese CNC Machining Manufacturers, especially those focused on export business, are experienced with high-mix, low-volume production. They can switch setups efficiently and manage diverse part numbers, which is ideal for customers that need multiple customized components rather than just a few standard parts. This flexibility is particularly valuable for startups, R&D projects, and specialized industrial equipment manufacturers.

Regions such as the Pearl River Delta (including Dongguan and Shenzhen) and the Yangtze River Delta have dense industrial clusters, rich supplier bases, and strong logistics infrastructure. Choosing CNC Machining Manufacturers in these areas often means better access to surface-treatment vendors, raw materials, and shipping services, as well as faster lead times and more convenient communication with experienced export-oriented factories.