From 1 piece to mass production, our one-stop custom services ensure a worry-free experience for you.

Help Center

Views: 222 Author: Rebecca Publish Time: 2026-01-22 Origin: Site

Content Menu

● Overview of the Stamping Die Components Market in Denmark

● Leading Stamping Die Components Manufacturers in Denmark

>> 1. Danfoss Tooling Solutions A/S

>> 2. DMT Stamping Technology ApS

>> 4. TT Mechanical Industries

● Why Choose Denmark for Stamping Die Components?

>> Exceptional Engineering Quality

>> Reliability and On-Time Delivery

>> Sustainable Production Practices

>> Global Export and OEM Capability

● Cooperation Between Danish Manufacturers and Global OEMs

>> China-Denmark Collaboration

● The Role of Technology in Modern Stamping Die Manufacturing

>> The Rise of Digital Manufacturing

>> Computer-Aided Engineering (CAE) Tools

>> Automation Solutions for Die Production

● Future Trends of Stamping Die Component Manufacturing in Denmark

● FAQs About Stamping Die Components in Denmark

>> 1. What materials do Danish manufacturers use for stamping die components?

>> 2. How do Danish suppliers support OEM services?

>> 3. Are Denmark's stamping die components suitable for automotive applications?

>> 4. Can international companies order customized die components from Denmark?

>> 5. How does partnership with Chinese manufacturers like U-NEED benefit the supply chain?

Denmark is known for its precision engineering, advanced manufacturing infrastructure, and strong commitment to quality standards. Within Europe's industrial ecosystem, Danish companies specializing in stamping die components have developed a reputation for excellence. This article explores the Top Stamping Die Components Manufacturers And Suppliers in Denmark, their market advantages, and how global buyers can benefit from partnering with them.

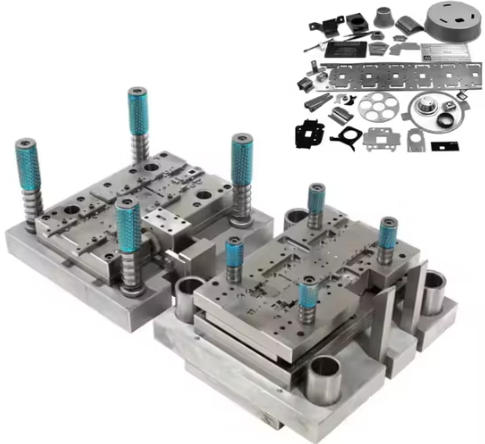

The stamping die industry has become integral to Denmark's manufacturing landscape, supporting sectors such as automotive, electronics, energy systems, and aerospace. Companies in this field produce essential tooling elements such as die blocks, guide posts, punches, bushings, ejectors, and precision molds.

Denmark's strategic focus on automation, sustainability, and precision has elevated its position within Europe's metalworking and tooling sectors. Top stamping die components manufacturers and suppliers in Denmark combine traditional craftsmanship with digital production systems, ensuring top quality and consistency.

- High-precision production — Danish manufacturers are recognized for extremely tight-tolerance components.

- Smart manufacturing — Integration of Industry 4.0 technologies for real-time monitoring and automated quality control.

- Customized solutions — Tailor-made stamping die components to match client-specific requirements.

- Sustainability focus — Use of eco-friendly materials and optimized energy consumption during manufacturing.

These strengths make Denmark one of the most reliable sources for stamping die components in Europe.

The following are some of the top stamping die components manufacturers and suppliers in Denmark, known internationally for their engineering capabilities, advanced machining facilities, and consistent export performance.

Danfoss is among the most recognized industrial groups in Denmark. Its tooling division specializes in die components and precision metal forming parts. With a focus on consistent tolerances and long-lasting durability, Danfoss serves clients across automotive and renewable energy sectors.

DMT Stamping Technology ApS provides high-performance stamping dies, press tools, and custom-designed components. The company operates an automated CNC and EDM workshop, enabling precision manufacturing at scale. Export customers appreciate their flexible OEM services and cost competitiveness.

Juel Engineering is one of the top stamping die components manufacturers in Denmark, supporting molds, dies, and fixture systems for electronic and mechanical applications. Their ISO-certified processes meet the expectations of aerospace and high-technology clients worldwide.

TT Mechanical offers die design, tool construction, and maintenance services under one roof. The company emphasizes short lead times, collaborative R&D, and advanced simulation technologies to optimize stamping die performance.

KVM International A/S produces both standard and custom die components for heavy-duty industrial applications. As one of the most experienced Danish manufacturers, it combines innovation with decades of toolmaking experience, serving a global client base.

These companies represent the professionalism and technical excellence that define Denmark's tooling and metal forming industry.

Choosing suppliers from Denmark ensures access to precision-engineered products, dependable partnerships, and strong after-sales support. Several advantages highlight the country's position as a global leader:

Denmark maintains one of the highest engineering education standards in Europe. Manufacturers use advanced CAD/CAM and finite element analysis (FEA) tools to design die components that achieve long service life and maintain stability under heavy production cycles.

Danish suppliers prioritize punctuality and reliability. Their production systems operate with real-time scheduling software, minimizing delays during OEM production.

Sustainability defines Denmark's industrial strategy. Many die component suppliers use recyclable materials, energy-efficient machines, and environmentally certified processes. This is a key factor for international brands emphasizing responsible sourcing.

Most of the top stamping die components manufacturers and suppliers in Denmark have extensive export experience. Their OEM and ODM services cater to clients from Europe, North America, and Asia. Danish companies are open to long-term cooperation with importers, distributors, and manufacturing brands looking for reliable partnerships.

As global supply chains evolve, Danish manufacturers increasingly cooperate with international OEMs and component distributors. They provide custom stamping die components that integrate with global assembly systems or fit into existing tooling designs.

In recent years, cooperation between Chinese and Danish manufacturers has expanded rapidly. Companies like U-NEED, a professional Chinese manufacturer specializing in high-precision CNC machining, plastic injection molding, silicone product molding, and metal stamping, serve as OEM partners for many Danish and European clients.

U-NEED's capacity for high-volume, precision machining complements the innovative design and engineering skills of Danish suppliers. This China-Denmark collaboration model enhances efficiency while maintaining global manufacturing standards.

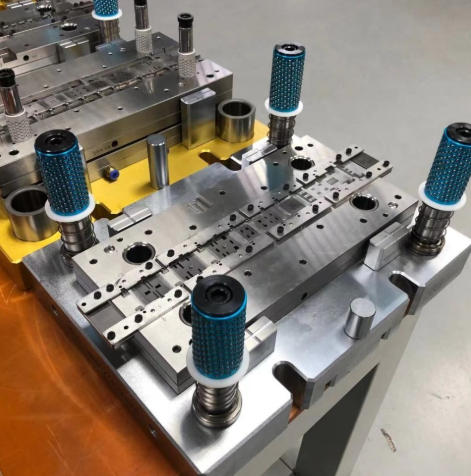

The integration of advanced technology has redefined the production of stamping die components in Denmark. The use of robotics, AI-based inspection, and precision machining is now standard practice.

Smart factories with interconnected systems monitor tool wear, surface finish, and accuracy in real-time. This approach reduces human error and maximizes equipment longevity.

CAE and CAD software help simulate die performance before actual production begins, identifying design weaknesses and optimizing geometry. Danish manufacturers lead Europe in applying such technologies efficiently.

Automation not only improves production speed but also ensures consistent precision. Robotic tool changers, CNC multi-axis milling machines, and EDM systems form the backbone of modern Danish tool shops.

When selecting among the top stamping die components manufacturers and suppliers in Denmark, global buyers should evaluate a few key factors:

- Experience in OEM and export operations.

- Precision standards such as ISO 9001, ISO/TS 16949, or AS9100 certifications.

- Capacity for prototyping and mass production.

- Lead times and shipping support.

- After-sales technical services and repair support.

Buyers focused on high consistency and technical reliability will find Danish manufacturers well-suited for long-term cooperation.

Technological progress continues to reshape Denmark's stamping die industry. AI-assisted quality monitoring, digital twins, and additive manufacturing are becoming central to die-making innovation.

In addition, the demand for lightweight materials — including aluminum and advanced alloys — is increasing, requiring new tooling designs that adapt to energy-efficient production. Danish firms remain at the forefront of integrating these new technologies while maintaining superior quality standards.

Denmark continues to be a leader in the field of precision tooling and metal forming systems. The Top Stamping Die Components Manufacturers And Suppliers in Denmark combine world-class engineering, automation excellence, and sustainable production practices to deliver superior products for global industries.

Companies such as Danfoss Tooling Solutions, DMT Stamping Technology, Juel Engineering, TT Mechanical, and KVM International represent the industry's best practices. For buyers seeking reliable OEM stamping die partners, Denmark provides unmatched quality and performance.

Furthermore, collaborations with Chinese manufacturers like U-NEED expand the supply network, offering an optimal balance between design innovation and manufacturing efficiency. As global industrial cooperation increases, Denmark's influence in the stamping die component sector will continue to grow.

Danish manufacturers commonly use tool steels such as SKD11, H13, and tungsten carbide, as well as specialized high-speed steels for durability and long service life.

Many manufacturers offer OEM and ODM solutions, assisting clients with design customization, prototype testing, packaging, and global logistics.

Yes. Denmark's die component manufacturers serve leading European automotive OEMs, ensuring compliance with ISO and IATF standards.

Absolutely. Most top stamping die components manufacturers and suppliers in Denmark provide customized tooling based on client specifications, CAD models, or sample components.

Collaborating with U-NEED enables cost-effective mass production, flexible design adjustments, and high-quality precision machining, making the supply chain more efficient and competitive.