From 1 piece to mass production, our one-stop custom services ensure a worry-free experience for you.

Help Center

Views: 222 Author: Rebecca Publish Time: 2026-01-02 Origin: Site

Content Menu

● How a Wire EDM Machine Works

● Main Components of a Wire EDM Machine

>> CNC Axes and Machine Structure

>> Wire Transport System and Guides

>> Dielectric System and Conductivity Control

● Cutting Speed, Productivity, and Cost Control

>> Evolution of Cutting Speed in Wire EDM

>> Key Factors Affecting Cutting Speed

>> Wire Consumption and Operating Economics

● Automatic Wire Threading and Process Automation

>> Role of Automatic Wire Threading

>> Best Practices for Maintaining Threading Performance

● Generator Technology, Electrolysis, and Surface Integrity

● Accuracy, Corner Control, and Skim Cutting Strategies

>> Corner Accuracy and Wire Lag

● Tooling, Fixturing, and Process Integration

>> Requirements for Modern Wire EDM Tooling

>> Practical Setup Considerations

● Typical Applications and Selection Guidelines

● Practical Optimization Checklist

● Frequently Asked Questions (FAQ)

>> 1. What materials can be processed with wire EDM

>> 2. How accurate is wire EDM compared with conventional CNC machining

>> 3. Is wire EDM suitable for production or only for tooling and prototypes

>> 4. Does wire EDM damage the material or create a problematic heat-affected zone

>> 5. What information should be provided when requesting a wire EDM quotation

Wire EDM (Wire Electrical Discharge Machining) is a high-precision, non-contact cutting process that uses a continuously fed wire electrode and deionized water to machine complex conductive parts with tight tolerances and excellent surface finishes. Wire EDM is widely used for difficult-to-machine materials, thin sections, and intricate geometries where conventional machining struggles.

Wire EDM is an electro-thermal machining process that removes material by controlled electrical discharges between a thin metal wire and a conductive workpiece submerged in dielectric fluid. Each spark locally melts or vaporizes a tiny volume of metal, allowing very fine features, sharp internal corners, and hard materials to be machined without mechanical cutting forces.

Key characteristics of wire EDM include:

- Non-contact cutting with no tool pressure, ideal for delicate or thin-walled parts.

- Excellent accuracy and repeatability, typically in the micron range on modern machines.

- Capability to cut hardened steels, carbide, titanium, Inconel, and other difficult alloys.

- Ability to produce complex 2D profiles and 3D tapers with multi-axis control.

For foreign OEMs, brand owners, wholesalers, and manufacturers, wire EDM is often the preferred technology when required geometry or tolerance cannot be achieved economically with milling, turning, or stamping.

A modern CNC wire EDM machine uses a continuously fed wire electrode, precision servo axes, and a dielectric system to control the spark erosion process. The wire never touches the workpiece; instead, a narrow gap is maintained and controlled by the machine's servo system.

Basic process steps:

1. The conductive workpiece is clamped and submerged in a dielectric tank, usually deionized water.

2. A thin wire, typically brass or coated brass, is fed from a supply spool through upper and lower guides, past the part, and into a take-up spool.

3. CNC control moves the axes (X, Y, and often U, V, Z) to follow a programmed path.

4. Pulsed voltage between wire and part generates sparks across the gap, removing material.

5. The dielectric flushes away eroded particles and cools both wire and workpiece.

Because the wire is continuously renewed from the spool, tool wear does not change the cut geometry, which is a major advantage over traditional cutting tools.

Modern wire EDM centers commonly provide 4- or 5-axis capability (X, Y, U, V, and Z) to produce complex tapers and genuine 3D forms. The upper head can offset in U and V, tilting the wire relative to the lower guide to generate draft angles and clearance on mold and die components.

- X-Y table: Positions the workpiece in the horizontal plane.

- U-V axes: Offset the upper wire guide to create tapers and 3D shapes.

- Z axis: Sets the height of the upper head and effective cutting height for tall parts.

For high-precision work, a rigid machine structure with good thermal stability is critical to maintain micron-level accuracy over long cutting times.

The wire transport system, wire guides, tensioning clutch, and pulleys are central to cut stability and accuracy. The system must feed fresh wire through the cut at controlled speed and tension to avoid vibration, deflection, or breakage.

Typical aspects of the wire system:

- Wire diameter usually ranges from about 0.05 mm to 0.25 mm, with 0.25 mm commonly used for general work.

- Brass wire is the standard choice, while coated wires support higher cutting speeds and improved flushing conditions.

- Carbide energizer plates transmit current to the wire and wear faster at higher current densities, requiring regular inspection and replacement.

Proper cleaning of guides and energizer plates is essential, as debris and wire shavings can clog the guides and cause wire breakage or failures in automatic wire threading.

Most wire EDM machines use deionized water as the primary dielectric fluid. Deionized water provides high flushing capability to remove chips and debris from the wire slot and efficient cooling for both wire and workpiece, supporting higher cutting speeds.

Water dielectric characteristics:

- Ionizes quickly, enabling high pulse frequencies and fine spark control.

- Is less insulating than EDM oil, so it can retain charge after each pulse.

- Requires controlled conductivity through filters and deionizing resin.

If the conductivity level becomes too high, wire breakage and unstable cutting are more likely. Some ultra-precision machines use oil dielectric to achieve extremely fine surface finishes with minimized surface damage, accepting lower cutting speeds in exchange for superior surface integrity and corrosion resistance in specific applications.

Early-generation wire EDM machines offered cutting speeds on the order of 1.5 to 2 square inches per hour, which are considered very slow by modern standards. Advances in generator technology, dielectric systems, stiffer tooling, and premium wire types have increased roughing rates to well above 20 square inches per hour under favorable conditions.

Modern systems, depending on machine design and setup, can achieve substantially higher material removal rates while maintaining acceptable accuracy and surface quality. In practice, however, usable productivity must consider the full cycle, including skim cuts, setup, automatic threading performance, and maintenance downtime.

Cutting speed is the result of multiple interacting parameters. The following table summarizes typical directions of influence on cutting rate:

| Parameter | Slower Setting | Faster Setting | Practical Note |

|---|---|---|---|

| Dielectric pressure | Low pressure | High pressure | Higher flushing improves chip evacuation but requires rigid tooling. |

| Wire type | Standard brass | Coated wire | Coated wires support higher current and larger spark gaps. |

| Wire diameter | Small diameter | Larger diameter | Larger surface area allows higher average current. |

| Wire tension | Excessively taut | Optimized, slightly lower | Too much tension risks breakage; too little allows deflection. |

| Nozzle distance | Very close to work surface | Optimized stand-off distance | Proper gap balances flushing efficiency and cut stability. |

Wire EDM productivity depends not only on peak roughing speed but also on total time per part, including skim passes and non-cutting activities. A balanced parameter set often yields better throughput than simply maximizing roughing speed.

Wire is a major consumable in EDM and its consumption is directly related to cutting time and feed rate. Smaller wire diameters provide more length per unit weight but carry less current and therefore lower maximum cutting speed, while larger wire diameters allow higher power at the cost of greater weight consumption per hour.

Standard brass wire is generally more economical per kilogram, whereas premium coated wires cost more but can significantly increase cutting speed and process stability in demanding materials or thick parts. When evaluating cost, businesses should consider overall machine earning capacity and avoid false economies that sacrifice throughput or reliability for small savings in wire cost.

In addition to wire, other consumables such as contacts, resin, guides, and filters are consumed faster at higher cutting rates, leading to more frequent maintenance and potential downtime. The optimal operating point is typically where consumable cost and machine availability support the lowest total cost per finished part.

Automatic wire threading (AWT) is one of the most impactful developments in wire EDM productivity. Instead of relying on manual re-threading after every break or when starting internal features, an automatic threader can re-establish the wire path without operator intervention.

Benefits of AWT include:

- Significant reduction in idle time caused by wire breaks or multi-cavity jobs.

- Ability to run long programs and complex parts with internal contours in a more unattended fashion.

- Flexibility to design cutting strategies that use multiple start positions, improving part stability and accuracy.

In many production environments, a reliable automatic threader improves capital equipment payback and enables practical overnight or lights-out operation.

Most threaders use a water-jet transport mechanism to carry the wire between the upper and lower guides. Because the wire is very small and the path is intricate, disciplined maintenance is necessary for high success rates.

Recommended practices include:

- Regularly cleaning guides, jets, and related channels to prevent clogs from debris and wire shavings.

- Replacing filters and deionizing resin on the schedule recommended by the machine manufacturer.

- Ensuring that wire type, diameter, tension, and feed parameters match the machine's threading specifications.

Neglecting automatic threading maintenance quickly leads to frequent threading failures, increased manual intervention, and reduced overall productivity, even if the core machine is capable of high performance.

Wire EDM generators deliver short, high-peak-current pulses with carefully controlled on-time and off-time to balance cutting speed, surface finish, and recast layer thickness. Due to the small contact area of the wire electrode, average current is limited, which makes pulse control especially important.

In water-dielectric systems, the fluid can remain partially charged after each discharge, leading to electrolysis if not mitigated. Electrolysis can cause surface discoloration or rust on steels, and may promote pitting, micro-cracking, or cobalt depletion in carbides. Over time, these effects can compromise dimensional stability and service life of tools and critical components.

Modern power supplies use specialized pulse patterns and alternating-voltage strategies designed to reduce residual charge in the dielectric. Operating with these low-electrolysis modes may slightly reduce cutting speed but improves surface integrity and long-term reliability, which is often the priority for high-value applications.

Wire EDM accuracy depends on both machine capability and chosen cut strategy. An overly aggressive rough cut on thick workpieces can cause wire bow or belly inside the kerf, leaving a curved profile that is difficult to fully correct with finishing passes.

To balance speed and precision:

- Use a controlled roughing pass that does not push the machine beyond stable cutting conditions.

- Plan sufficient skim cuts at lower power to achieve final size and desired surface finish.

- Allow for extra skims when tolerances are very tight or surface quality requirements are stringent.

If the roughing pass introduces significant deviation in the middle of the part, the flexible wire may continue following that path during skimming, making dimensional correction time-consuming and sometimes incomplete.

At higher cutting speeds and in thicker materials, corner accuracy often becomes a limiting factor. Once the wire leaves the guide and enters the workpiece, the forces from cutting and flushing can pull it away from the ideal geometric path, leading to excess stock on internal corners and over-cutting on external corners.

To address these issues, advanced controls and CAM systems apply:

- Corner slowdown algorithms that reduce feed near sharp changes in direction.

- Gap and lag compensation to account for the physical position of the wire within the cut.

- Path modification and test cuts to fine-tune geometry for specific materials and thicknesses.

For critical features, multiple test runs and small program adjustments may be required to achieve the desired accuracy under real operating conditions.

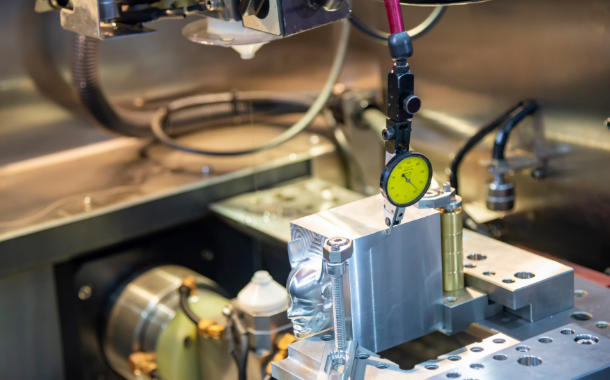

As flushing pressures and cutting speeds increased, early lightweight tooling systems became insufficient. Higher fluid forces and part overhang generated vibration and made it difficult to hold tight tolerances.

Modern wire EDM tooling offers:

- Robust clamping systems that withstand high-pressure flushing and tall part setups.

- Modular and repeatable fixtures with accuracy in the range of a few microns.

- Multi-part holding options that support batch production and unattended operation.

Such tooling enables seamless transfer of parts between different machines, including milling and grinding centers, while maintaining coordinate integrity. This integration helps reduce setup time and errors for complex, multi-process workflows.

For predictable and repeatable outcomes in production environments:

- Use dedicated fixtures that minimize overhang and maximize rigidity close to the cutting zone.

- Carefully establish and document datums, offsets, and reference surfaces for repeat jobs.

- Plan slug removal, clamping changes, and cut sequencing in the program to avoid unintended part movement.

For buyers and engineers, working with a supplier that has standardized EDM tooling and setup procedures can significantly reduce trial time, improve repeatability, and shorten lead times on new and repeat orders.

Wire EDM is particularly effective for complex, tight-tolerance parts in conductive materials where other processes face limitations. Common application areas include:

- Mold and die components with precise tapers, clearances, and complex contours.

- Progressive stamping and fine-blanking dies requiring sharp internal corners and hardened tool steels.

- Aerospace and medical components demanding burr-free edges and controlled thermal impact.

- Micro-scale features and thin sections that would deform under mechanical cutting forces.

Compared with laser and plasma cutting, wire EDM is slower but provides superior tolerance, surface finish, and edge quality, especially for thick or hardened materials. When full part cost is considered, including finishing and rejected parts, EDM often proves competitive for precision-critical work.

To maximize performance, cost efficiency, and part quality on wire EDM equipment, consider the following checklist:

1. Match wire to the application

- Use standard brass for general jobs and cost control.

- Select coated wire for higher speed, demanding materials, or thick workpieces.

2. Manage dielectric conditions

- Maintain proper conductivity using fresh resin and clean filters.

- Adjust flushing pressure to ensure chip evacuation without compromising fixture stability.

3. Optimize cutting strategy

- Avoid overly aggressive rough passes on thick parts.

- Schedule sufficient skim cuts with appropriate power levels for final size and finish.

4. Maintain equipment proactively

- Clean guides, nozzles, energizer plates, and threading paths according to schedule.

- Monitor contact wear, wire tension systems, and axis accuracy.

5. Use automation effectively

- Leverage automatic wire threading and multi-part fixturing for unattended shifts.

- Standardize job setups and programs for frequently repeated parts.

A supplier that consistently follows these practices can deliver stable quality, predictable lead times, and competitive pricing on high-precision components.

If your company needs high-precision metal parts, mold inserts, plastic-related tooling, silicone components, or stamped metal parts produced within a single integrated supply chain, collaborating with a capable OEM partner can significantly simplify your sourcing. As a China-based manufacturer specializing in high-precision machined components, plastic product manufacturing, silicone product manufacturing, and metal stamping, U-NEED offers one-stop OEM support for overseas brand owners, wholesalers, and producers.

Send your drawings, technical specifications, and annual demand forecasts to U-NEED now to receive an engineering review focused on manufacturability, cost optimization, and delivery planning, and start building a stable long-term supply solution for your precision components.

Wire EDM can process any electrically conductive material, including tool steels, stainless steels, titanium, nickel-based superalloys, aluminum alloys, and cemented carbides. Non-conductive materials require conductive inserts or hybrid approaches if they are to be formed in EDM-related processes.

Modern wire EDM machines can routinely achieve micron-level positioning and tight geometric tolerances, particularly when using multiple skim passes. While high-end milling centers can also reach very high precision, wire EDM offers advantages for sharp internal corners, extremely thin features, and hardened materials that are difficult to machine mechanically.

Wire EDM is suitable for both tooling and production, particularly in low- to medium-volume runs where tolerances are tight and materials are difficult to machine. With automation, multi-part fixturing, and night-shift operation, wire EDM can be highly competitive for serial production of high-value components.

Wire EDM does generate a thin recast layer; however, with optimized generator settings and properly planned skim cuts, the heat-affected zone is typically very small and well controlled. Advanced low-electrolysis cutting modes further reduce micro-cracking and surface damage, making the process suitable for demanding tooling and many critical industrial applications.

To obtain an accurate quotation, it is helpful to provide a complete CAD model or fully dimensioned drawing, along with information about material grade, hardness, tolerance requirements, surface finish targets, and expected quantities. Indicating critical features and functional surfaces allows the EDM supplier to propose suitable wire types, cutting strategies, and fixturing concepts.