Milling Machines: Versatile Tools for Precision Machined Parts

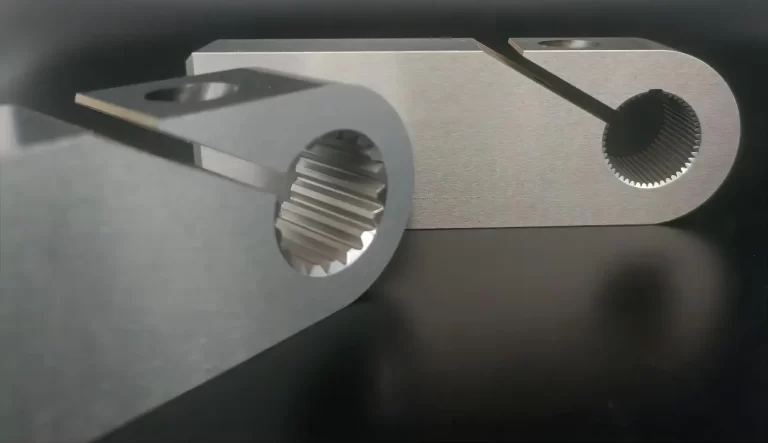

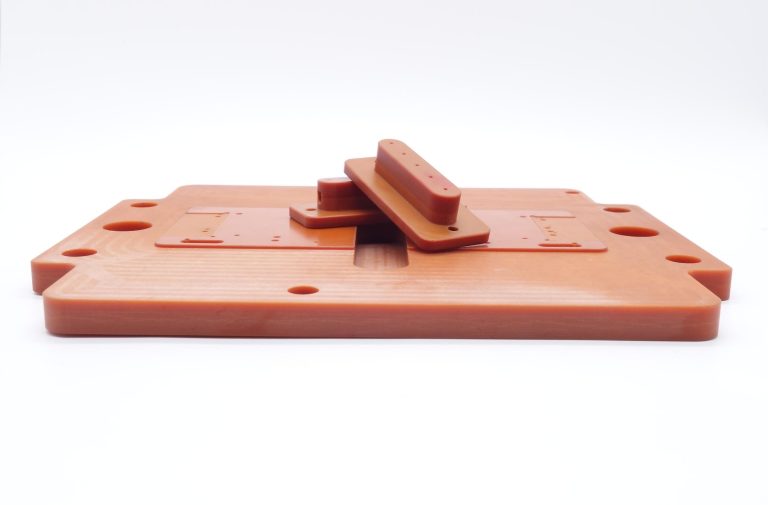

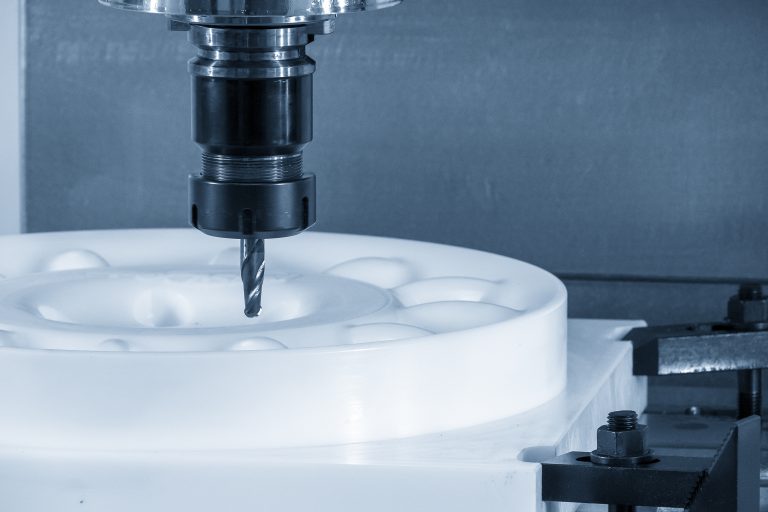

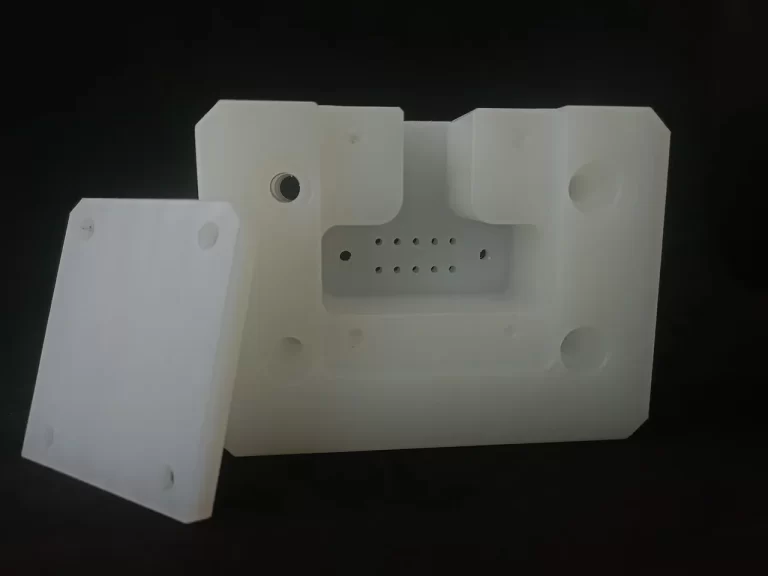

Versatile Tools for Precision Machined Parts What is Milling Machine? A milling machine is a power-driven tool to achieve material removal. It has a stationary worktable, a spindle holding the milling cutter, and various controls to move the workpiece and cutting tool. What Can A Milling Machine Do? Usually the rotary motion of the milling cutter is the main motion, and the movement of the workpiece and the milling cutter is the feed motion. Milling machines can process planes, grooves, gear, and various curved surfaces, etc. What is a Milling Machine Used For? Milling machines are used for a wide range of applications, including: – Flat Surfaces: They excel at creating flat surfaces on workpieces, like base plates, mounting brackets. – Contoured Parts: Milling machines can produce workpieces with complex contours…