What is the Difference Between 6061 and 6063Aluminum?

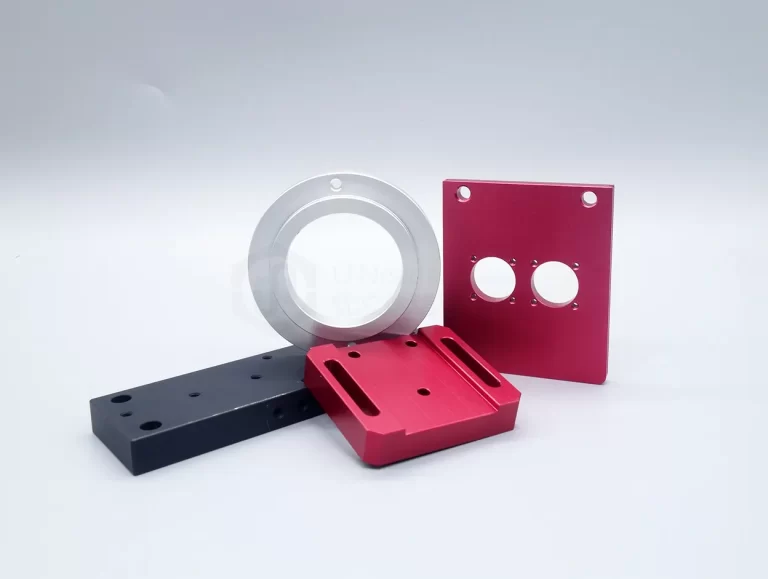

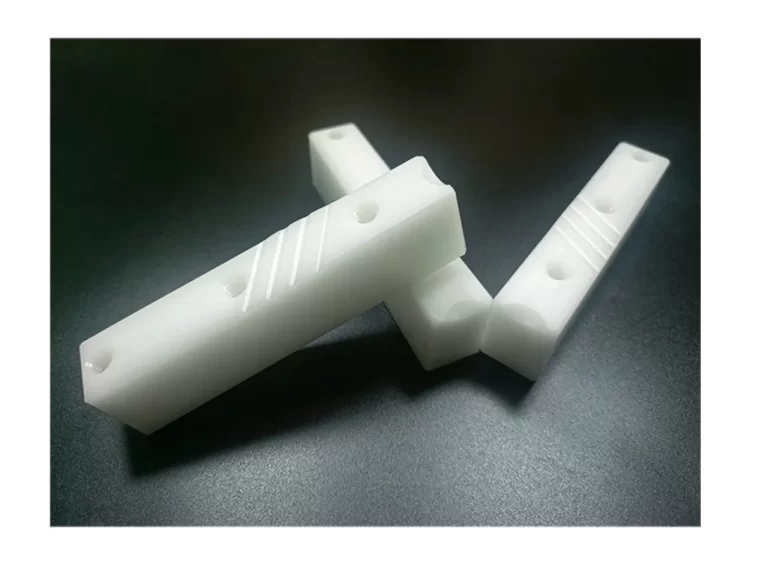

What is the Difference Between 6061 and 6063 Aluminum? Aluminum Alloy 6061 in Review: 6061 Aluminum is a precision-machined, versatile and widely used alloy known for its excellent strength-to-weight ratio. It offers good corrosion resistance,machinability, and weldability. Alloy 6061 is commonly used in structural applications, such as aerospace components, marine fittings, and general machinery parts. Aluminum Alloy 6061 6061 Aluminum is a precision-machined, versatile and widely used alloy known for its excellent strength-to-weight ratio. It offers good corrosion resistance, machinability, and weldability. Alloy 6061 is commonly used in structural applications, such as aerospace components, marine fittings, and general machinery parts. Aluminum Alloy 6063 6063 Aluminum is an architectural alloy, primarily recognized for its exceptional extrudability, making it a popular choice for extruded profiles. It possesses good corrosion resistance, moderate strength, and excellent surface finish….