What is the Difference Between 6061 and 6063 Aluminum?

Aluminum Alloy 6061 in Review:

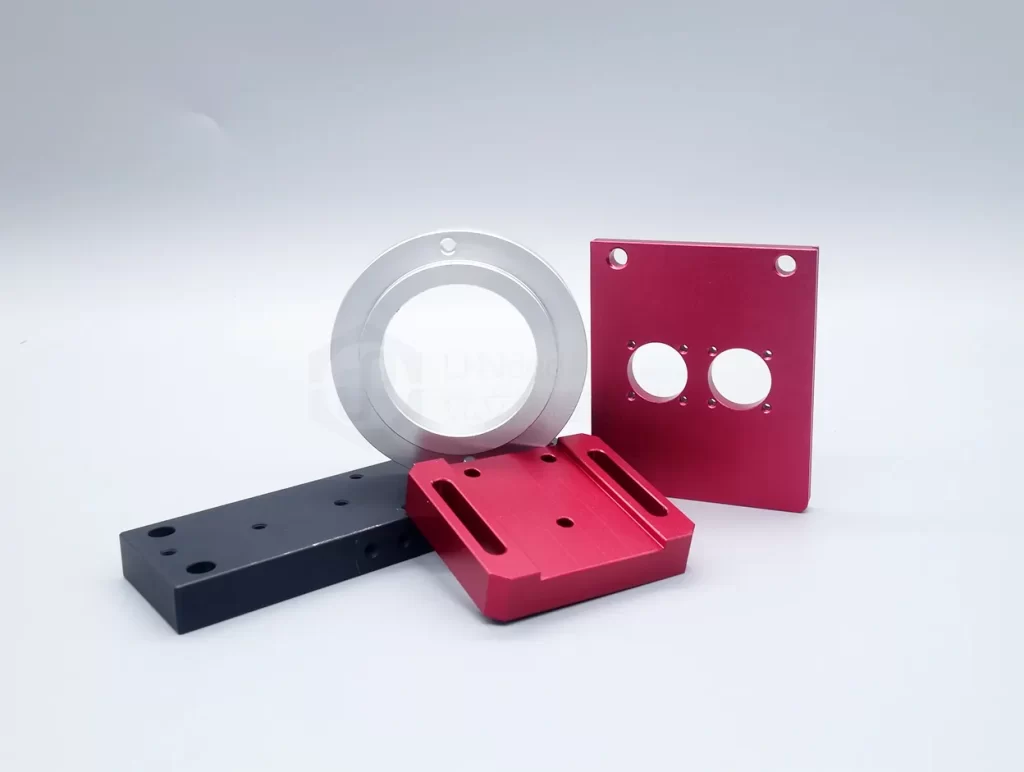

6061 Aluminum is a precision-machined, versatile and widely used alloy known for its excellent strength-to-weight ratio. It offers good corrosion resistance,machinability, and weldability. Alloy 6061 is commonly used in structural applications, such as aerospace components, marine fittings, and general machinery parts.

Aluminum Alloy 6061

6061 Aluminum is a precision-machined, versatile and widely used alloy known for its excellent strength-to-weight ratio. It offers good corrosion resistance, machinability, and weldability. Alloy 6061 is commonly used in structural applications, such as aerospace components, marine fittings, and general machinery parts.

Aluminum Alloy 6063

6063 Aluminum is an architectural alloy, primarily recognized for its exceptional extrudability, making it a popular choice for extruded profiles. It possesses good corrosion resistance, moderate strength, and excellent surface finish. Alloy 6063 finds applications in architectural framing, window and door frames, and electrical components.

Characteristics of Aluminum 6061 vs 6063:

While 6061 Aluminum and 6063 Aluminum share some similarities, they differ in certain key aspects, including compositional variances, mechanical properties, and applications. Let’s explore these differences further.

| Characteristics | Aluminum6061 | Aluminum 6063 |

| Versatility | Good | Good |

| Tensile Strength | Great | Good |

| Corrosion Resistance | Good | Great |

| Extrudability | Good | Great |

| Machinability | Good | Great |

| Surface Quality | Good | Great |

| Geometric Complexity | Good | Great |

Versatility:

Both 6061 and 6063 offer versatility in their respective applications, providing a wide range of possibilities for various industries due to its excellent formability and machinability.

Tensile Strength:

6061 has a higher tensile strength compared to 6063. 6061 is suitable for structural applications, and 6063 is suitable for applications that prioritize formability over strength.

Corrosion Resistance:

6061 exhibits good resistance to corrosion but may require surface treatments for enhanced protection. And 6063 offers good resistance to atmospheric and marine corrosion.

Extrudability:

6061 can be extruded, it requires more force than 6063 due to its higher strength. 6063 is renowned for its superior extrudability, making it easier to create intricate profiles and shapes.

Machinability:

6061 is easily machinable, allowing for precise shaping and manufacturing. 6063 is generally easier to machine compared to 6061, facilitating efficient manufacturing processes.

Surface Quality:

6061 provides a smooth and polished surface finish, making it suitable for aesthetic applications. While 6063 provides a better smooth and aesthetically pleasing surface finish.

Geometric Complexity:

6061 can handle complex shapes and structures due to its higher strength. While 6063 is well-suited for applications that require complex extruded profiles and geometries.

Applications for 6061 Aluminum

Applications for 6063 Aluminum

material mix variance

The compositional variances between 6061 and 6063 Aluminum contribute to their different mechanical properties. While both alloys contain aluminum as the primary element, they differ in the amounts of alloying elements such as silicon, magnesium, and copper. 6061 has higher levels of silicon and copper, while 6063 has higher amounts of magnesium and silicon. These variances affect their strength, formability, and extrudability.

price comparisons

The cost of 6061 and 6063 can vary depending on factors such as market conditions, quantity, and supplier. However, in general, 6063 tends to be slightly less expensive than 6061 due to its lower processing requirements.