From 1 piece to mass production, our one-stop custom services ensure a worry-free experience for you.

Help Center

Views: 222 Author: Loretta Publish Time: 2025-12-23 Origin: Site

Content Menu

● Key Factors Affecting CNC Machining Cost

>> Material Selection and Machinability

>> Design Complexity and Geometry

>> Batch Size and Production Volume

>> Finishing and Post Processing

● Cost Drivers by Part Type and Process

>> Overview of Process Level Cost Drivers

● How CNC Machining Cost Is Calculated in Practice

● Practical Strategies to Reduce CNC Machining Costs

>> Design For Manufacturability From the Start

>> Choosing the Right Material Strategy

>> Batch Planning and Order Strategy

>> Optimizing Finishing and Quality Requirements

● How an Integrated OEM Partner Helps Control Machining Cost

>> Engineering Support and DFM Collaboration

>> Flexible Prototype to Production Path

>> Cost Effective Global OEM Service

● Step by Step: How to Work With a CNC OEM Supplier

>> 1. Prepare Clear Technical Documentation

>> 2. Request a Detailed and Transparent Quote

>> 3. Review and Implement DFM Suggestions

>> 4. Approve Samples and Quality Plan

>> 5. Move Into Stable Production and Continuous Improvement

● Take the Next Step to Optimize Your CNC Machining Costs

● Frequently Asked Questions (FAQ)

>> 1. What information is needed to get an accurate CNC machining quote?

>> 2. Is CNC machining or metal stamping more cost effective for my part?

>> 3. How can I reduce CNC machining costs without hurting quality?

>> 4. Can one OEM partner handle both prototypes and mass production?

>> 5. How long does it typically take to receive CNC machined parts from overseas?

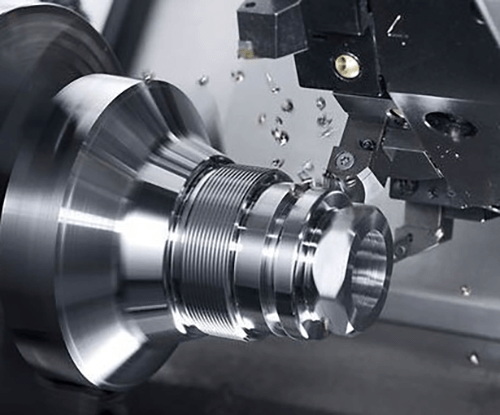

Understanding CNC machining cost is critical if you are an engineer, buyer, or brand owner working with custom metal, plastic, silicone, or stamped parts. Costs are influenced by a mix of technical, commercial, and supply chain factors, from material choice and part geometry to volume, tolerances, finishing, and supplier capability. By optimizing each of these levers, you can often reduce total part cost significantly without sacrificing quality or reliability.[1]

This section provides a structured CNC machining cost breakdown so buyers and engineers can quickly identify the biggest savings opportunities. A clear understanding of these core drivers also makes communication with your manufacturing partner more efficient and transparent.[1]

Material is usually one of the most important cost drivers in CNC projects. It affects raw material expenditure, machining time, tool wear, and scrap.[1]

How material impacts cost:

- Harder materials such as stainless steel or titanium require slower cutting speeds and more robust tools, which increases cycle time and tooling cost.

- High value alloys make material waste more expensive, especially when parts have low material utilization or large stock allowances.

- High machinability materials like aluminum 6061 or many engineering plastics can be cut faster with lower tool wear, reducing both time and unit cost.

For many functional components, aluminum 6061 offers a strong balance of strength, corrosion resistance, and low machining cost, making it a useful default for prototypes and stable designs.[1]

The more complex a part is, the more it usually costs to machine. Design choices that look minor in CAD can translate into significant increases in setup time, programming effort, and machining difficulty.[1]

Typical cost-increasing features:

- Multi axis machining that requires 4 axis or 5 axis equipment and multiple setups.

- Tight tolerances that demand slower feeds, additional tool passes, and more inspection.

- Intricate geometries such as thin walls, deep pockets, undercuts, or small radii that increase the risk of chatter, deformation, and tool breakage.

Whenever functionality allows, aim for simpler, more machinable geometries and apply tight tolerances only where they are genuinely critical to performance or assembly.[1]

CNC machining has front loaded costs for programming, fixture design, and setup, which means the per unit cost decreases as volume rises. Economies of scale are therefore an essential factor when planning a project.[1]

- Small batches or single prototypes carry higher unit costs because setup and programming are spread over only a few pieces.

- Medium and large runs benefit from continuous machine operation, optimized tool paths, and more efficient resource use, reducing the cost of each additional part.

If your design is stable and demand is predictable, ordering an economical quantity can reduce unit price and avoid repeated setup charges.[1]

Raw CNC parts are often functional but may not meet cosmetic, corrosion, or regulatory requirements until additional processes are applied. Each finishing step adds cost, time, and sometimes yield loss if parts fail final inspection.[1]

Common finishing operations include:

- Anodizing for aluminum components, either decorative or hard anodizing.

- Plating, such as zinc, nickel, or chrome on steel parts for protection and appearance.

- Painting, powder coating, or polishing to achieve specific surface textures or visual effects.

To control cost, differentiate clearly between surfaces that truly need premium finishes and those where a basic or raw finish is acceptable.[1]

A clear understanding of how cost behaves across different processes helps you choose the right manufacturing route for each part. Metal machining, plastic machining, silicone production, and metal stamping all have distinct cost structures.[1]

Part / Process Type | Main Cost Drivers | Typical Best Use Case |

CNC metal machining | Material grade, cycle time, tolerances, surface finish | High precision structural and functional components |

CNC plastic machining | Material type, heat buildup, risk of deformation, tool sharpness | Low volume housings, fixtures, medical, and optical parts |

Silicone product manufacturing | Mold cost, cavity count, silicone grade, manual or automated trimming | Seals, gaskets, soft touch components, consumer and medical applications |

Metal stamping | Tooling cost, press speed, material utilization, automation level | High volume thin metal parts with stable and repeatable shapes |

By matching each part to the most appropriate process, you can balance cost, precision, and lead time more effectively.[1]

Although pricing models vary, most CNC machining quotes are built from a similar set of components. Knowing these elements helps you ask informed questions and compare offers from different suppliers.[1]

Typical cost components include:

- Programming and engineering time for CAD review, DFM feedback, CAM programming, and fixture design.

- Machine time calculated from the hourly rate of the machine multiplied by the estimated machining hours.

- Direct labor for part setup, in process inspection, deburring, cleaning, and final quality checks.

- Material and expected scrap, including test pieces and any loss during setup.

- Finishing, assembly, packaging, and shipping costs as required by the project.

A transparent breakdown gives buyers more control and enables suppliers to propose targeted optimizations rather than generic price reductions.[1]

The most effective way to reduce CNC machining costs is to work systematically across design, material, volume planning, and finishing choices. Many of these improvements require no compromise on function, safety, or durability.[1]

Design for manufacturability, or DFM, focuses on creating parts that are easy, stable, and economical to produce. Applying DFM principles early can remove unnecessary complexity before it becomes embedded in tooling and processes.[1]

DFM checklist before freezing your design:

1. Review tolerance requirements and relax non critical dimensions where feasible.

2. Use tool friendly radii and avoid sharp inside corners that demand special cutters.

3. Minimize deep, narrow pockets and extremely thin walls that are prone to vibration.

4. Consolidate features so they can be machined in fewer setups.

5. Replace deeply machined logos or decorative details with laser marking or printing if suitable.

Building a short internal review around these points before each RFQ can significantly lower machining time and reject rates.[1]

Material selection should balance performance, cost, ease of machining, and global availability. In many projects, small material adjustments can offer substantial savings without affecting end user experience.[1]

Consider the following guidelines:

- For structural metal parts, start with common grades such as aluminum 6061 or standard carbon steels unless your application clearly requires a special alloy.

- For covers, fixtures, and non load bearing components, evaluate engineering plastics, which may cut both machining time and weight.

- For wear intensive or sealing applications, slightly higher material cost can be justified if it reduces scrap, rework, and field failures.

Working closely with your supplier to evaluate alternatives will often uncover combinations that maintain performance while lowering total project cost.[1]

Thoughtful planning of batch size and order timing can dramatically improve cost efficiency, especially for repeat parts or long term programs.[1]

Useful practices include:

- Grouping similar parts made from the same material into one production batch to minimize tool changes and setup.

- Ordering economical quantities that balance lower unit cost against storage and cash flow constraints.

- Freezing design and specification before placing large orders to avoid expensive engineering changes and re qualification.

A clear annual or quarterly forecast shared with your OEM supplier can further support better planning, purchasing, and logistics.[1]

Over specification of finishes and inspections is a frequent source of avoidable cost. Aligning quality requirements with real functional risk is essential.[1]

To keep finishing and quality effective but lean:

- Separate functional surfaces from cosmetic ones and assign differentiated requirements.

- Reserve premium coatings, polishing, or special textures for visible or touch critical areas.

- Define an inspection plan that fits the risk level, such as higher sampling for safety critical parts and lighter inspection for simple accessories.

This approach maintains confidence in product performance while keeping processing steps practical and efficient.[1]

An OEM partner that can handle precision machining, plastic parts, silicone products, and metal stamping under one roof provides advantages in both cost control and consistency. Centralized engineering and purchasing reduce communication friction and allow more holistic optimizations.[1]

Working directly with engineers familiar with CNC machining and related processes makes it easier to refine a design before it hits the workshop. This collaboration can identify issues that might otherwise cause delays or cost overruns later.[1]

Key aspects of effective engineering support include:

- Early DFM feedback based on your models and drawings.

- Practical proposals for simplifying geometry or adjusting tolerances.

- Process selection guidance to determine whether CNC machining, silicone molding, or stamping is best for each component.

This proactive approach reduces trial and error and leads to more stable, predictable cost structures.[1]

A smooth path from prototype to mass production is crucial for product launches. Choosing a partner that can support each stage allows designs to be refined and industrialized without switching suppliers.[1]

A typical path may involve:

- Rapid CNC prototypes to verify fit, function, and assembly.

- Pilot runs to confirm capacity, yield, and process stability.

- Transition to larger production volumes with standardized work instructions and inspection plans.

This continuity shortens learning curves and helps keep cost and quality under control as volume scales.[1]

For overseas brands and wholesalers, cost effectiveness involves more than the lowest unit price. Reliable lead times, consistent quality, and responsive communication all contribute to total cost of ownership.[1]

A strong OEM partner will typically:

- Provide clear and itemized quotations so you understand material, machining, finishing, and tooling charges.

- Offer volume based pricing options and help you choose optimal batch sizes.

- Use modern machinery, programming software, and inspection tools to maintain competitive efficiency.

By aligning on long term cooperation and transparent communication, both sides gain the ability to optimize cost structures over multiple projects.[1]

The following workflow improves both cost outcomes and user experience for overseas customers working with machining and manufacturing partners.[1]

- Supply 3D models in a common format along with 2D drawings that show key dimensions and tolerances.

- Include material specifications, finish requirements, and any standards or regulations that apply.

- Highlight critical features and surfaces where performance margins are tight.

Well prepared documentation reduces quotation time, ambiguity, and the chance of misinterpretation.[1]

When you send an RFQ, ask for a breakdown that includes:

- Material type, usage estimate, and potential alternatives.

- Machining and setup costs separately, including any special fixtures.

- Finishing, packaging, and logistic options.

- Tooling charges for processes such as silicone molding or metal stamping.

A transparent quote makes comparison easier and helps you see where optimization will have the most impact.[1]

If your supplier returns with suggestions, treat them as an opportunity to reduce risk and cost. Many design changes at this stage are inexpensive but powerful.[1]

- Evaluate each suggestion against functional, safety, and aesthetic needs.

- Update models and drawings to reflect agreed changes.

- Confirm that the new design is now the official version before moving forward.

This cooperative process builds trust and improves the value of every subsequent order.[1]

Before mass production, it is wise to confirm that the parts and inspection methods match your expectations.[1]

- Review prototype or pre production samples carefully for both dimensions and appearance.

- Agree on an inspection and testing plan, including sampling levels and reporting.

- Address any deviations immediately and adjust documentation where necessary.

Once both sides sign off, production can start with a shared understanding of what success looks like.[1]

As batches repeat, data on yield, quality, and delivery performance becomes available. This information can be used to refine both cost and process.[1]

- Plan regular reviews to discuss potential improvements or material changes.

- Adjust batch sizes, shipment frequency, and packaging as demand becomes clearer.

- Capture lessons learned and apply them to new product introductions.

Over time, this structured approach leads to a more robust and cost efficient supply chain.[1]

If you are a brand owner, wholesaler, or manufacturer looking to control CNC machining and related production costs while maintaining high quality, the most effective move is to partner with an experienced OEM supplier that understands precision machining, plastics, silicone products, and metal stamping. By sharing your drawings, requirements, and volume plans, you can receive a detailed cost breakdown, targeted DFM suggestions, and a tailored production strategy that fits your business goals. Reach out now to request a transparent quotation and start turning your designs into reliable, cost efficient parts with a professional OEM team by your side.

You should provide 3D models, detailed 2D drawings, material specifications, surface finish requirements, expected quantities, and any special testing or certification requirements. This information allows the supplier to estimate machining time, material usage, and finishing processes realistically.[1]

CNC machining is typically more cost effective for complex geometries, lower volumes, and designs that may still change, because it requires little or no dedicated tooling. Metal stamping is generally more economical for high volume, relatively flat parts once stamping dies are built and production is stable.[1]

Focus on design for manufacturability, such as simplifying geometries, relaxing non critical tolerances, and choosing more machinable materials. In addition, avoid unnecessary finishing steps and specify inspection requirements that match the real risk profile of your application.[1]

Many professional OEM suppliers can support both rapid CNC prototypes and full scale production across multiple processes. This continuity allows you to refine designs with the same team that will eventually manage mass production, improving consistency and reducing transfer risk.[1]

Lead time depends on design complexity, volume, and the capacity of your supplier, but many projects can move from confirmed order to shipment within a few weeks. Factoring in shipping and customs, planning ahead with clear forecasts and stable designs helps ensure reliable delivery schedules.[1]