From 1 piece to mass production, our one-stop custom services ensure a worry-free experience for you.

Help Center

Views: 222 Author: Loretta Publish Time: 2025-12-21 Origin: Site

Content Menu

● Japan's Strength in Precision Mold Engineering

● Representative Precision Mold Companies in Japan

>> Ultra-Precision Mold Specialists

>> General Precision Mold Parts Manufacturers and Suppliers

● Typical Capabilities of Japanese Precision Mold Suppliers

>> Mold Making and Part Fabrication

>> Validation, Sampling, and Maintenance

● U-NEED: A Flexible Chinese OEM Partner

>> Benefits for Overseas Buyers

● Japan–China Collaboration in Precision Mold Supply Chains

>> Typical Collaboration Models

>> Industries That Benefit Most

● How to Choose Precision Mold Parts Manufacturers and Suppliers in Japan

>> Technical and Process Capabilities

>> Engineering Communication and Support

>> Quality Systems and Certification

● Working With U-NEED as an OEM Extension

>> Typical Project Flow With U-NEED

● Practical Tips for International Buyers

● FAQs About Precision Mold Parts Manufacturers and Suppliers

>> 1. How do Japanese Precision Mold Parts Manufacturers and Suppliers stand out globally?

>> 2. Why should overseas brands consider combining Japanese suppliers with a Chinese OEM like U-NEED?

>> 3. What kinds of parts can U-NEED produce as an OEM partner?

>> 4. How should buyers evaluate potential Precision Mold Parts Manufacturers and Suppliers in Japan?

Japan is home to some of the world's most advanced precision mold technologies, serving demanding industries such as automotive, electronics, medical devices, and optics. Precision Mold Parts Manufacturers and Suppliers in Japan are recognized for ultra-tight tolerances, long tool life, and consistent quality, which makes them attractive partners for overseas brands, wholesalers, and manufacturers seeking OEM solutions.

For buyers who want top‑level performance with competitive cost, combining Japanese Precision Mold Parts Manufacturers and Suppliers with experienced Chinese OEM factories like U-NEED offers a powerful, flexible sourcing strategy for high-precision metal, plastic, silicone, and stamped components.

Japanese Precision Mold Parts Manufacturers and Suppliers have earned a global reputation by blending deep craftsmanship with cutting-edge automation and stringent quality disciplines. Decades of investment in precision machining, process control, and skilled training underpin this competitive edge.

- Many Japanese companies operate highly automated factories with robotic handling, AI‑assisted machining, and in‑process measurement to stabilize quality and improve productivity.

- The industry's culture emphasizes kaizen (continuous improvement), which drives ongoing refinement of machining parameters, maintenance plans, and inspection routines.

- Precision tooling from Japan is especially valued when component reliability and long service life are critical, such as in connectors, electronic housings, optical units, and medical devices.

By relying on these strengths, Precision Mold Parts Manufacturers and Suppliers in Japan provide global customers with tools and components that maintain accuracy over large production volumes and long operating cycles.

Several leading companies illustrate the capabilities and breadth of Precision Mold Parts Manufacturers and Suppliers in Japan. Although each has its own specialization, together they showcase the ecosystem available to international OEM buyers.

Some Japanese manufacturers focus on ultra-precision molds for high-end markets such as semiconductors, optics, and advanced electronics.

- These companies invest in specialized CNC machines, ultra-fine grinding, and high-stability environments to achieve micron and even sub‑micron dimensional accuracy.

- Their molds are used in applications like lenses, light guides, microconnectors, and microfluidic components, where surface quality and precision directly affect product performance.

Such ultra-precision suppliers often work closely with R&D departments and design houses worldwide, helping refine product geometry to match what is technically achievable in tooling and mass production.

Beyond niche ultra-precision players, Japan has a wide layer of suppliers that focus on high-quality, general precision work.

- These Precision Mold Parts Manufacturers and Suppliers provide mold bases, cores, cavities, ejector pins, slides, lifters, and inserts for a broad spectrum of molds.

- They support automotive, consumer products, household appliances, industrial hardware, and many other sectors that need consistent, repeatable tooling performance.

Because of Japan's reputation for reliability, these suppliers are often asked to handle complex, multi-cavity, and multi-step molds where process stability and long-term repeatability are priorities.

When working with Precision Mold Parts Manufacturers and Suppliers in Japan, overseas customers can expect a broad and technologically advanced set of capabilities. These services usually span the full life cycle of a mold or precision mechanical part.

- 3D CAD/CAE design, often with mold-flow simulations, structural analyses, and thermal studies to optimize gating, cooling, and venting.

- Design for manufacturability (DFM) consultation to refine part geometry, ease demolding, reduce warpage, and lower tooling cost without compromising function.

- High-precision CNC milling and turning for hardened steels, pre‑hardened steels, aluminum alloys, and special alloys used for mold components.

- EDM and wire‑EDM machining for intricate details, sharp corners, deep ribs, and complex parting line geometries.

- Precision surface grinding and polishing, including mirror finishes for optical or high‑clarity plastic parts.

- Mold trials on in‑house injection machines, with dimensional reports and process parameter recommendations for mass production.

- Preventive maintenance, refurbishing, and modification services to extend mold life or adjust tools to new requirements.

- In some cases, local technical support for overseas customers via partner networks or subsidiaries.

These bundled capabilities make Japanese Precision Mold Parts Manufacturers and Suppliers a strong choice for projects where quality, risk control, and stable long‑term performance are more important than lowest initial tooling price.

While Japan excels in engineering and high-end tooling, many buyers also need cost-effective production capacity, rapid turnaround, and diversified part manufacturing. U-NEED, a Chinese OEM company, has emerged as an attractive partner for brands that benchmark against Precision Mold Parts Manufacturers and Suppliers in Japan but want more competitive unit costs for global markets.

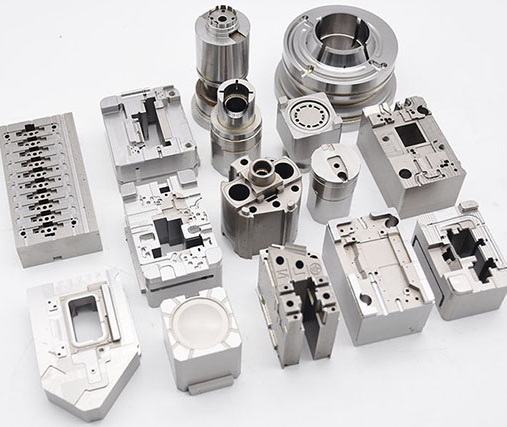

U-NEED focuses on high-precision mechanical components and multi-material manufacturing. Its capabilities include:

- Custom CNC machining of metal and plastic parts with tight tolerances, suited for both prototypes and mass production.

- Production of metal stamping parts using progressive dies, transfer dies, and single‑stage dies for brackets, terminals, housings, and structural elements.

- Mold-related manufacturing, such as components for injection molds, die‑casting molds, and stamping dies, enabling U-NEED to act as an extended workshop for mold makers.

- Plastic product manufacturing through injection molding, including engineering resins used in automotive, electronics, and industrial applications.

- Silicone product manufacturing, such as seals, gaskets, keypads, and customized silicone accessories for consumer and industrial uses.

This wide process coverage allows one-stop OEM solutions, reducing the need for multiple suppliers and simplifying project management for international customers.

By cooperating with U-NEED, foreign brands, wholesalers, and manufacturers can:

- Lower per‑part and tooling costs compared with doing all work in high-cost markets, while still meeting stringent technical standards.

- Access flexible order quantities, from low-volume prototypes and pilot runs to large-scale mass production for established products.

- Shorten development cycles by quickly iterating samples and engineering changes thanks to responsive project management and integrated workshops.

- Diversify their supplier base geographically, balancing Japanese Precision Mold Parts Manufacturers and Suppliers with cost-effective Chinese production.

For companies in North America, Europe, and other Asian markets, this combination of Japanese design excellence and Chinese OEM manufacturing offers a practical path to competitive differentiation.

The global mold and precision parts supply chain increasingly relies on cross-border collaboration. Japanese Precision Mold Parts Manufacturers and Suppliers often take the lead in design, innovation, and critical components, while Chinese OEMs drive volume manufacturing under strict quality agreements.

Several collaboration models are common between Japanese and Chinese partners:

- Design in Japan, manufacture in China: Japanese engineers finalize the mold concept and critical dimensions, then U-NEED and similar OEMs handle CNC parts, mold components, and mass‑produced stamped or molded parts.

- Hybrid tooling strategy: Critical inserts or cores that demand extreme precision are produced in Japan, while supporting components, frames, and standard elements are manufactured in China.

- Lifecycle support: Initial mold trials and acceptance may occur in Japan, followed by long-term maintenance, spare parts, and related component production in Chinese factories.

These models balance cost, performance, and risk, ensuring that complex molds meet global standards without locking buyers into a single high‑cost supply point.

Industries that especially benefit from joint use of Precision Mold Parts Manufacturers and Suppliers in Japan and Chinese OEMs like U-NEED include:

- Automotive and EV: Connectors, sensor housings, battery components, interior trim, and under‑hood parts demand robust molds, precision metal parts, and durable plastics.

- Consumer and industrial electronics: Enclosures, connectors, switches, cooling structures, and mechanical interfaces require fine details and tight dimensional control.

- Medical and laboratory equipment: Diagnostic cartridges, fluid connectors, pump components, and protective housings rely on reliable, repeatable molds and high-quality plastic or silicone parts.

- Aerospace and high-tech machinery: Specialized mounting brackets, precision spacers, and complex mechanical interfaces blend CNC machining, stamping, and custom molding.

In all of these sectors, buyers can use Japanese suppliers for key molds and U-NEED for cost-efficient production of the resulting components and related precision parts.

Selecting the right Precision Mold Parts Manufacturers and Suppliers requires a structured evaluation approach. Buyers should look beyond price and consider technical depth, communication, and long-term support.

- Review tolerance capabilities and surface finish ranges for CNC machining, EDM, and grinding processes.

- Confirm experience with materials similar to your own project, including specific tool steels, engineering plastics, and elastomers.

- Ask for case studies or reference components that demonstrate relevant complexity and accuracy.

- Evaluate the supplier's responsiveness and technical clarity during early RFQ and DFM discussions.

- Check whether design engineers can provide practical optimization suggestions rather than simply quoting as‑is.

- Confirm that the supplier can share detailed inspection reports, mold‑flow analyses, or simulation results if necessary.

- Ensure that the supplier operates under recognized quality systems and applies consistent inspection at critical stages.

- Look for the use of CMMs, optical measurement systems, hardness testing, and surface roughness checks where appropriate.

- Discuss traceability requirements, especially for regulated industries like medical or aerospace, and confirm that the supplier can meet them.

When these elements are in place, buyers can have greater confidence that the selected Precision Mold Parts Manufacturers and Suppliers will deliver reliable tools and parts over the long term.

For many projects, especially those targeting global markets or price-sensitive segments, combining high-end Japanese tooling with U-NEED's OEM capabilities is a pragmatic strategy.

A common flow when collaborating with U-NEED as an OEM partner may include:

1. Requirement definition

The customer provides drawings, 3D models, technical requirements, expected volumes, and any applicable standards or test methods.

2. Engineering review and quoting

U-NEED's engineering team reviews manufacturability, suggests optimizations, and provides quotations for CNC parts, stamped parts, plastic products, silicone components, or mold components.

3. Sampling and validation

Trial samples or pilot runs are produced, together with dimensional and functional reports. Minor design adjustments are incorporated quickly if needed.

4. Mass production and logistics

Once validated, U-NEED scales up production, manages process controls, and arranges packaging and shipping tailored to the customer's supply chain.

5. Continuous improvement

Feedback from the field is used to refine tolerances, surface treatments, or assembly features, improving long-term cost and performance.

This process allows international customers to maintain strict quality benchmarks inspired by Precision Mold Parts Manufacturers and Suppliers in Japan, while leveraging U-NEED's flexibility and cost advantages.

When you are building a sourcing strategy around Precision Mold Parts Manufacturers and Suppliers in Japan and a Chinese OEM partner like U-NEED, several practical steps help ensure success.

- Start with a clear technical specification that defines critical dimensions, surface finishes, materials, and testing methods.

- Prioritize a pilot phase where you can thoroughly test a smaller batch before committing to full-volume tooling or mass production.

- Communicate openly about expected annual volumes, future variants, and lifecycle plans, so that both Japanese suppliers and U-NEED can plan capacity and investments.

- Use non-disclosure agreements and clear IP clauses when sharing proprietary designs or technologies across borders.

- Build multi-year relationships rather than single-batch transactions, which encourages suppliers to invest more deeply in process optimization and quality improvements tailored to your business.

By following these guidelines, overseas brands, wholesalers, and manufacturers can make the most of the strengths offered by Precision Mold Parts Manufacturers and Suppliers in Japan and by OEM partners in China.

Japan remains one of the strongest global hubs for high-end Precision Mold Parts Manufacturers and Suppliers, combining traditional craftsmanship with modern automation, simulation, and rigorous quality systems. These suppliers play a vital role in industries where dimensional stability, micro-level precision, and long tool life are essential.

At the same time, cost and scalability are critical factors in today's markets. By pairing Japanese engineering and mold expertise with a capable Chinese OEM such as U-NEED, overseas brands, wholesalers, and manufacturers can secure competitive advantages in cost, lead time, and supply chain flexibility without compromising on quality. This collaborative approach enables robust, efficient production of precision metal parts, plastic components, silicone products, and metal stampings that serve demanding applications worldwide.

Japanese Precision Mold Parts Manufacturers and Suppliers stand out through their ability to achieve extremely tight tolerances, consistent long-term tool performance, and very stable processes. They invest heavily in high-end CNC, EDM, and grinding equipment and maintain a culture of continuous improvement and strict quality control that ensures repeatable results across large production volumes.

Overseas brands gain the high reliability and technical sophistication of Japanese Precision Mold Parts Manufacturers and Suppliers, while U-NEED provides cost‑effective, scalable OEM manufacturing of parts and related components. This combination allows customers to meet demanding performance standards yet still achieve competitive pricing, flexible MOQs, and rapid response to changes in design or demand.

U-NEED can produce a wide range of parts, including high-precision CNC machined metal and plastic components, metal stamping parts, injection-molded plastic products, and customized silicone items such as seals, gaskets, and functional accessories. This breadth of capability lets U-NEED support customers who source molds or precision standards from Japanese suppliers and then need a reliable manufacturing base for finished components.

Buyers should assess technical capabilities, proven experience with similar materials and parts, communication quality, and the robustness of the supplier's quality management system. It is helpful to review case studies or reference parts, examine inspection practices, and conduct a phased project starting with prototypes or small trial runs before committing to large investments in tooling or long-term contracts.

Before contacting suppliers, buyers should prepare clear 2D drawings or 3D models, functional requirements, expected quantities, material specifications, surface finish targets, and any relevant standards. Having this data ready enables precise quotations, more accurate DFM feedback, and a smoother transition from design to sampling and then to mass production, whether working directly with Japanese Precision Mold Parts Manufacturers and Suppliers, with U-NEED, or with both in a coordinated supply chain.