From 1 piece to mass production, our one-stop custom services ensure a worry-free experience for you.

Help Center

Views: 222 Author: Rebecca Publish Time: 2026-01-25 Origin: Site

Content Menu

● EDM Hole Drilling vs Conventional Drilling: Which Process Is Best for Precision Parts?

● What Is Conventional CNC Hole Drilling?

● Core Technical Differences Between EDM and CNC Drilling

● When to Choose EDM Hole Drilling

● When to Choose Conventional CNC Drilling

>> Ideal CNC Drilling Use Cases

● Hole Quality: Surface Finish, Burrs, and Structural Integrity

● Limitations and Trade Offs of Each Method

>> EDM Hole Drilling Limitations

● EDM Hole Drilling Machines: What Makes Them Different?

● Practical Selection Guide: How Engineers Should Decide

● Real World Application Scenarios

● Design Tips to Improve Hole Manufacturability

● How a Full Service OEM Partner Uses Both Technologies

● Take Action: Get a Tailored Drilling Strategy for Your Next Project

● FAQs About EDM Hole Drilling vs CNC Drilling

>> 1. Is EDM hole drilling always more accurate than CNC drilling?

>> 2. Can EDM replace all conventional drilling operations in my parts?

>> 3. Does EDM damage the material around the hole due to heat?

>> 4. When should I specify deburring or reaming for CNC drilled holes?

>> 5. How early should I involve a manufacturing partner in my drilling strategy?

EDM hole drilling and conventional CNC drilling each excel in different scenarios, especially when you care about precision, material hardness, and overall production cost. This enhanced guide helps engineers, buyers, and OEM partners choose the right process for their next project while improving manufacturability and lifecycle performance.

When you need holes in hardened steel, carbides, or high-temperature alloys, EDM hole drilling offers ultra precise, burr free results that conventional drilling struggles to match. For general purpose, high volume hole making in materials like aluminum, plastics, or mild steel, conventional CNC drilling is usually faster and more economical.

Both technologies can coexist in a well designed manufacturing strategy: EDM handles critical, deep, or micro holes, while CNC drilling covers structural and functional holes in less demanding conditions. As an OEM or brand owner sourcing from China, understanding the strengths of each method helps you specify the right process and avoid quality or cost surprises.

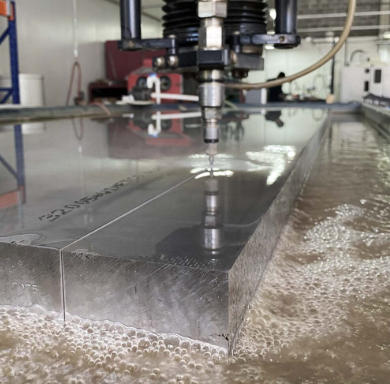

EDM (Electrical Discharge Machining) hole drilling uses rapid electrical discharges between a tubular electrode and a conductive workpiece to erode material and form a hole. Instead of a rotating drill bit, the electrode operates inside a dielectric fluid that cools the process and flushes away eroded particles.

Because the tool never physically touches the part, EDM is a non contact process that eliminates cutting forces and minimizes mechanical stress. It can produce extremely precise, burr free holes in hardened steel, carbides, titanium, Inconel, and other alloys that are difficult to machine with conventional tools.

Conventional CNC hole drilling removes material with rotating cutting tools such as twist drills, step drills, or end mills driven by a high speed spindle. It is the most common hole making process in CNC machining and is ideal for simple to moderately complex hole patterns in a wide variety of parts.

Modern CNC machines support advanced drilling strategies like peck drilling, high speed drilling, and combined drilling tapping cycles to improve chip evacuation and cycle time. However, because it is a contact based process, accuracy and surface finish can degrade due to tool wear, heat generation, and vibration.

The table below summarizes the main performance differences between EDM hole drilling and conventional CNC drilling.

| Feature | EDM Hole Drilling | CNC Hole Drilling |

|---|---|---|

| Material compatibility | Conductive materials only such as steel, titanium, Inconel, carbides | Most machinable materials including plastics, aluminum, and mild steel |

| Tool contact | Non contact electrical erosion | Direct mechanical contact via cutting edges |

| Typical hole size range | Micro to medium, about 0.1 mm to 6 mm | Broad range, about 0.5 mm to 50+ mm |

| Achievable tolerance | Extremely tight, near ±0.002 mm with proper setup | Moderate, around ±0.05 mm in typical production |

| Depth capability | Excellent for deep, narrow holes with 30:1 or higher depth to diameter ratios | Limited by tool rigidity and chip evacuation efficiency |

| Speed | Slower, especially for larger diameters | Generally faster for most medium and large holes |

| Surface finish | Very smooth, burr free, minimal heat affected zone | Often needs deburring, reaming, or finishing passes |

| Tool wear | Minimal due to absence of cutting forces | Higher wear, especially in hard or abrasive materials |

These differences mean EDM and CNC drilling are not interchangeable. Each is optimized for specific hole sizes, depths, and material conditions.

EDM hole drilling is the preferred option when precision and material hardness are the main challenges.

- Micro holes in critical components such as fuel injector nozzles and medical device features where burrs or deformation cannot be tolerated.

- Cooling holes in turbine blades and other aerospace components that require deep, narrow passages in heat resistant alloys.

- Starter holes for wire EDM when the material is too hard or the geometry too complex for conventional drilling.

- Hard tool steels, carbides, and superalloys that rapidly wear out conventional drill bits.

Because EDM does not generate cutting forces, it is also suitable for thin walled or delicate parts where mechanical drilling might cause distortion or cracking.

Conventional CNC drilling is the workhorse solution for most standard industrial and consumer components.

- Bolt holes, pilot holes, and tapped holes in brackets, housings, frames, and structural parts.

- Large diameter holes where EDM would be too slow and too costly.

- Batch and mass production of parts in aluminum, plastics, or mild steel where throughput and cost per piece matter most.

- Applications where tolerances are moderate and minor deburring or finishing is acceptable.

CNC drilling also integrates well with milling, tapping, and boring operations in a single setup, which helps reduce fixture changes and overall cycle time.

Hole quality is often as important as dimensional tolerance, especially in fluid, air, and fatigue critical applications.

EDM holes are typically burr free straight off the machine, with smooth surfaces and no mechanical deformation of the surrounding material. Because there is no tool pressure, the process avoids micro cracks or work hardening around the hole, which supports better fatigue performance in demanding applications.

CNC drilled holes often require secondary operations such as deburring, countersinking, or reaming to reach similar levels of finish and dimensional accuracy, especially for small diameters or deep holes. In harder materials, tool wear can introduce taper, chatter marks, or small positional errors if cutting parameters are not closely controlled.

For critical parts, it is helpful to define post drilling finishing requirements directly in the drawings, so suppliers can choose the correct process and quality control methods.

Neither drilling method is perfect. Knowing their limitations helps you set realistic expectations and decide on the most economical approach.

- Cannot process non conductive materials such as most plastics, composites, or glass.

- Slower for large diameter holes, which makes it unsuitable for high volume large hole production.

- Machines and electrodes are more expensive and usually require specialized technicians.

- Tool wear increases quickly in hardened or abrasive materials, raising tooling cost and affecting consistency.

- Deep holes are limited by tool deflection, chip evacuation challenges, and chatter at high aspect ratios.

- Achieving ultra tight tolerances may require multiple passes, special tooling, or combining processes.

A balanced process plan often uses CNC drilling for structural and non critical holes and reserves EDM for features where its benefits are clearly justified.

Dedicated EDM hole drilling machines are built for precision and automation rather than sheer metal removal rate. They are usually compact and equipped with multi axis positioning systems to align the electrode accurately to complex surfaces and angles.

Many systems offer automatic electrode changers so the machine can switch between different diameters or replace worn electrodes without manual intervention. Advanced EDM drilling setups can produce holes as small as 0.1 mm in tough metals, enabling intricate cooling schemes, micro fluid channels, and high density hole arrays. This capability is especially valuable in aerospace, mold, and die making environments that depend on repeatable, high accuracy features.

To choose between EDM and conventional drilling for a specific project, consider the following steps.

1. Check material type

If the material is non conductive, such as plastic or certain composites, conventional CNC drilling is required. If the material is hardened steel, carbide, or a superalloy, EDM becomes a strong candidate.

2. Define hole size and depth

For micro holes around 0.1 to 1 mm or deep holes with high aspect ratios, EDM is usually the better choice. For medium to large diameters, for example 5 to 50 mm or larger at moderate depth, CNC drilling is more efficient.

3. Evaluate tolerance and quality requirements

If the design specifies very tight tolerances and burr free edges, EDM offers a clear advantage. If moderate tolerances and a post drilling deburring step are acceptable, CNC drilling typically offers lower cost.

4. Consider production volume and budget

For high volume production of standard parts, CNC drilling usually delivers a lower cost per piece. For prototypes, small batches, or high value components, the precision of EDM may justify its higher unit cost.

Working through these criteria helps teams document their process choices and communicate clearly with manufacturing partners.

The following scenarios highlight how the choice between EDM and CNC drilling affects performance and cost.

- Aerospace turbine blade cooling: Deep, small diameter holes in nickel based superalloys rely on EDM to achieve required precision and thermal performance.

- Automotive brackets and frames: Large numbers of bolt and mounting holes in mild steel or aluminum are best produced with CNC drilling to minimize cycle time.

- Medical device micro features: Burr free micro holes in stainless steel or titanium often depend on EDM to avoid secondary finishing and preserve surface integrity.

In each case, the application context determines which process delivers the most reliable and cost effective outcome.

Thoughtful hole design can significantly improve manufacturability, regardless of whether you choose EDM or CNC drilling.

- Use standard drill sizes whenever possible to reduce tool changeovers and custom tooling costs.

- Avoid unnecessarily tight tolerances on non critical holes and reserve micron level tolerances for truly functional features.

- Group holes with similar sizes and depths to reduce setups and tool changes.

- Clearly specify whether deburring, chamfering, or reaming is required on the drawing.

These simple design practices help suppliers select the most suitable equipment and process settings for your parts.

A full service OEM supplier that offers high precision machining parts, plastic product manufacturing, silicone product manufacturing, and metal stamping can integrate both EDM and CNC drilling in one complete process chain.

Structural frames or stamped metal parts can be produced and drilled quickly using CNC machines for speed and cost efficiency. Critical interface holes, fluid control passages, or micro features on the same assembly can then be finished by EDM, so you pay for EDM level precision only where it delivers clear functional benefits.

For plastic and silicone components, CNC machining is used where post molding drilling or shaping is necessary, while metal inserts or overmolded components may receive EDM drilled features before assembly. This combination gives you a more flexible and robust production solution.

If your project involves precision metal parts, plastic assemblies, silicone components, or metal stamping, the choice between EDM hole drilling and conventional CNC drilling will directly affect both performance and cost. To avoid guesswork, share your drawings, models, and functional requirements with a capable OEM partner that understands both technologies. A team like U NEED can analyze your design, recommend the optimal drilling process for each feature, and provide a clear quotation that balances accuracy, lead time, and budget. Contact us now to discuss your parts and receive a targeted manufacturing proposal for your next production run.

Contact us to get more information!

EDM can generally achieve tighter tolerances and better surface finishes, especially on hard materials and very small holes. Actual accuracy still depends on machine condition, setup quality, and the experience of the operator.

No. EDM is limited to conductive materials and is relatively slow for large holes. It is most effective for difficult, high precision, or deep features, while conventional drilling remains the better option for most standard holes.

EDM uses localized thermal energy, but when parameters are well controlled, it creates a very small heat affected zone. It does not introduce mechanical stress and is designed to protect the structural integrity of the surrounding material.

You should specify deburring or reaming when hole edges are sealing surfaces, mating interfaces, or fatigue critical locations. In these cases, burrs or surface defects could cause leakage, misalignment, or premature failure.

Involving your OEM partner during the design stage allows time to review tolerances, suggest process improvements, and determine where EDM is necessary and where CNC drilling is sufficient. Early communication helps avoid costly design changes later.