What is the profile grinding process?

profile grinding

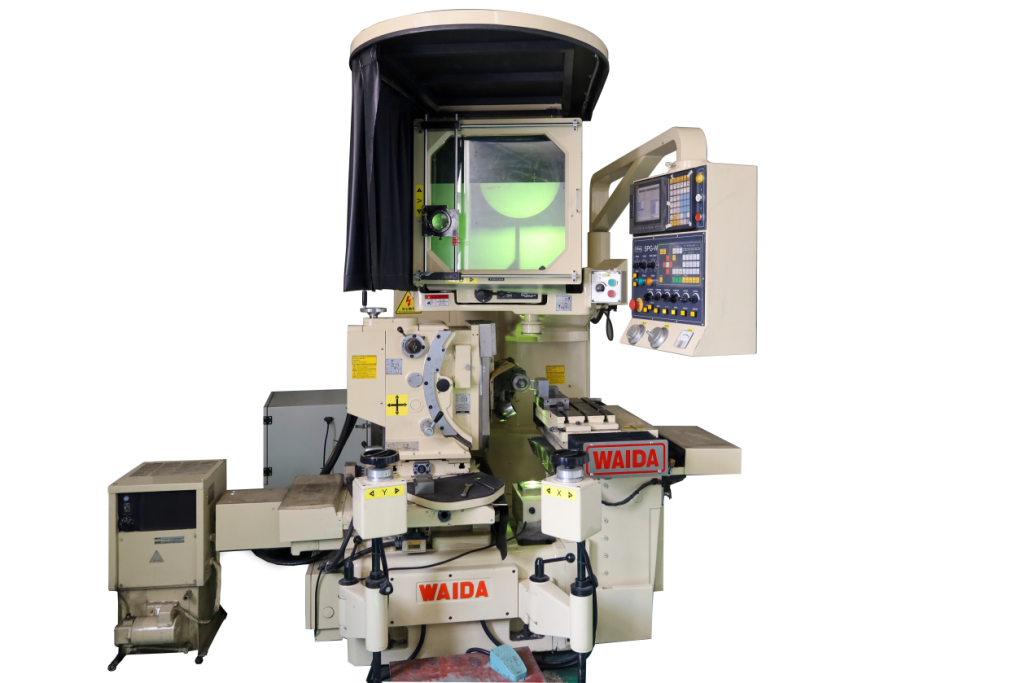

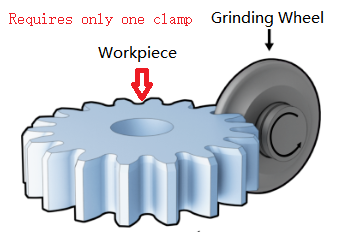

Profile grinding is also known as projection grinding, form grinding, and copy grinding. In this process, a workpiece is projected at a magnification of many times onto a product shape drawing. A grinding wheel is operated by numerical control or manual control, and copy grinding is performed with the workpiece overlaid onto the projected drawing.

What are the advantages of profile grinding?

- Requires only on clamp.

- Machine a very large number of geometries.

- Machine high hardness materials that are difficult to measure directly using a vernier or micrometer calipers.

- Creates a fine and high-accuracy shape.

- Reduce number rework and scrapped products.

What can be machined by profile grinding?

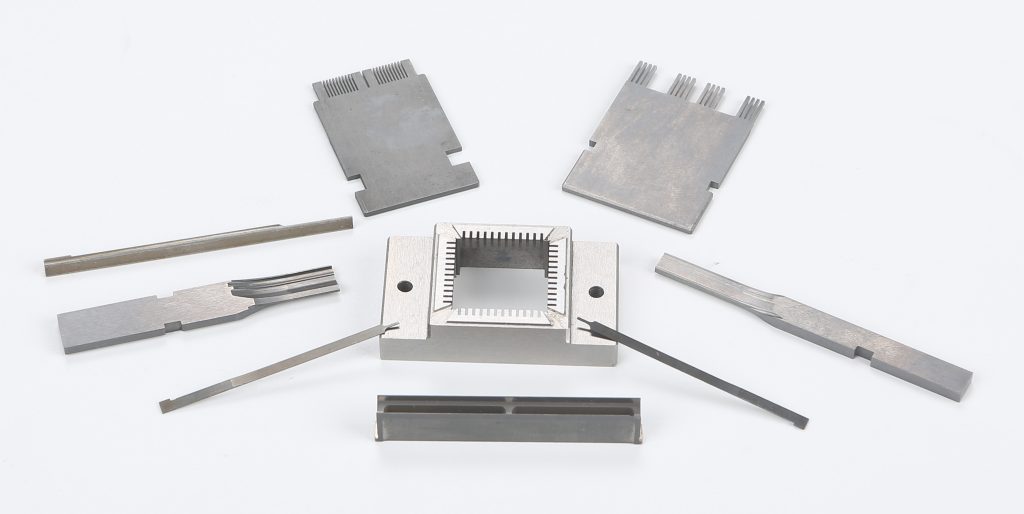

Usage: High-precision mold parts (punches and dies), special tools, cylindrical parts, etc.

Material: Carbide, tool steel, cermet, ceramic, CBN, high speed steel

Application industries: automotive, aerospace, electronics, medical technology, machine tool and die/mold, and so on.

What are the differences among OD grinding (Outside diameter grinding or External cylindrical grinding) , ID grinding (Inside diameter grinding or Internal cylindrical grinding), Centerless grinding, surface grinding, and Profile grinding?

| Machining Methods | Machining Shapes | Working Principle |

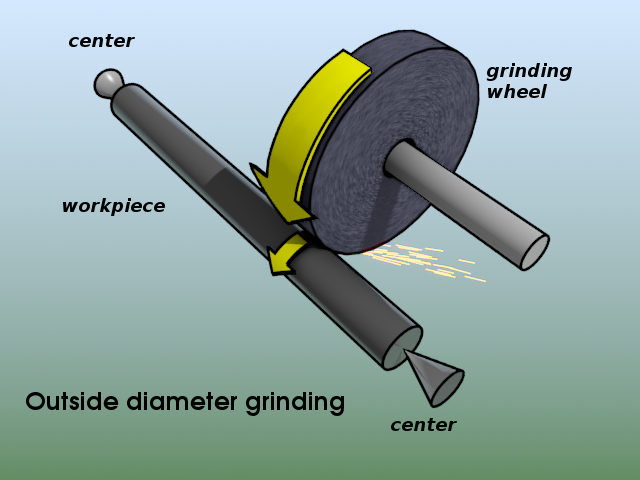

| OD grinding | To grind the outside surfaces and its shoulder ends of cylinder, cone, or others. |  |

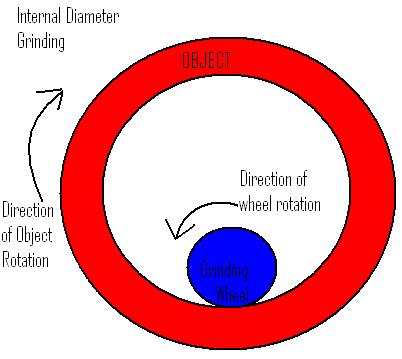

| ID grinding | To grind the inside surfaces and its shoulder ends of cylinder, cone, or others. |  |

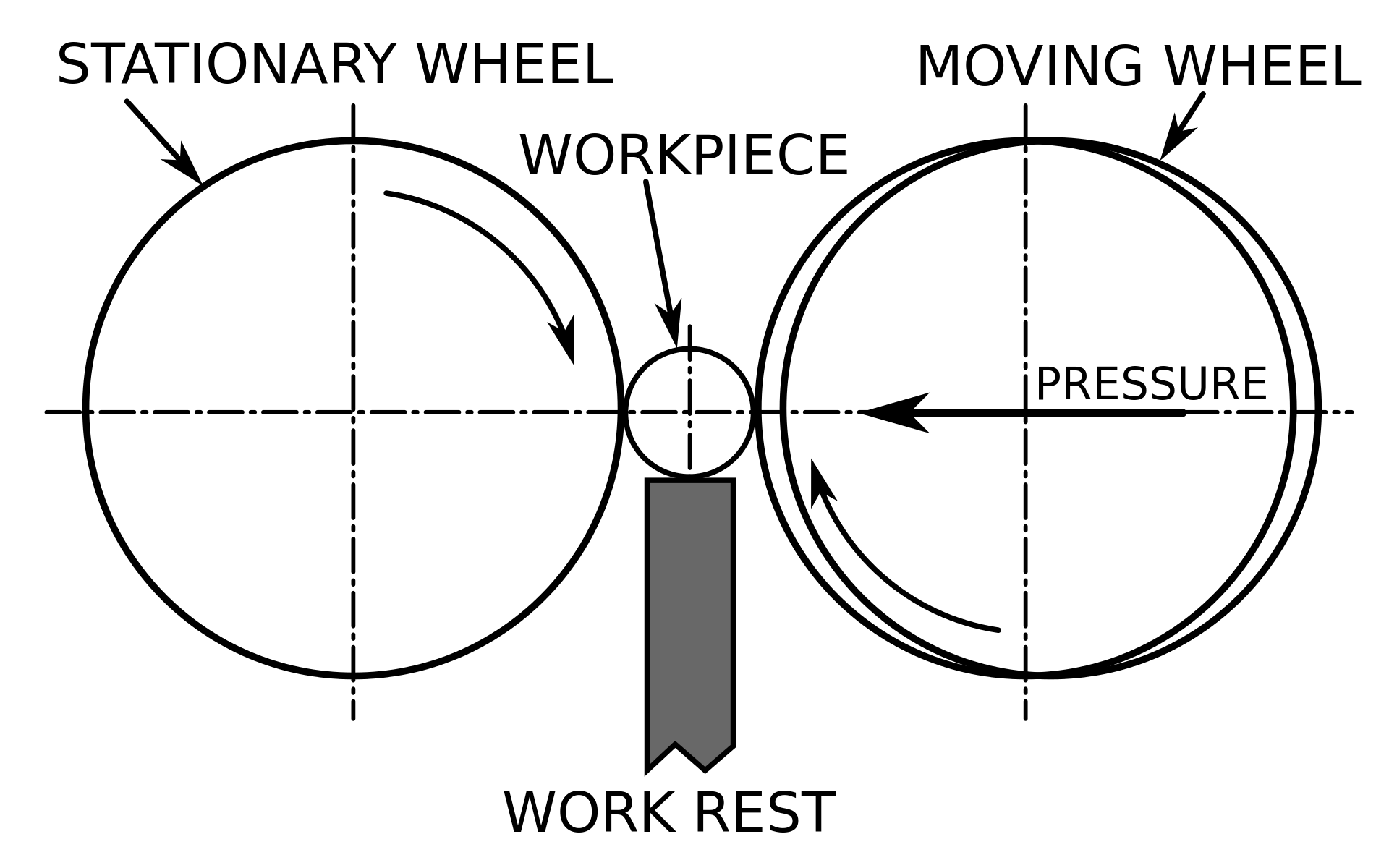

| Centerless grinding | To grind and polish the cylindrical surfaces of various rings, shafts, tubes, and sleeves. |  |

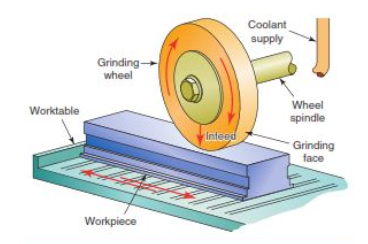

| Surface grinding | To grind the flat-shaped workpiece. |  |

| Profile Grinding | To process complicated shapes with micron-order accuracy and high hardness materials, such as carbide. |  |

U-Need has a rich experience in profile grinding machining that ensures easy customization to suit your exact needs. Welcome your inquiry.