Types of Metal Stamping

Metal Stamping

Stampingis a forming processing method that relies on press machines and dies to apply external force to plates, sheets, strips, pipes and profiles to create plastic deformation or separation, so as to obtain the stamping parts with required shape and size. Stamping and forging are both plastic processing , also known as pressure processing.

Metal stamping process is realized by stamping dies, and stamping includes various forming manufacturing process. The metal stamping machine almost refers to a machine press or metal stamping press. According to the process classification, it can be divided into two groups: separation process (or die cutting process ) and forming process. As seen the below table for

| more clear information: | ||||

| No. | Group | definition | Process | Description |

| 1 | Separation | This process aims to separate the stamping parts and the scraps, while ensuring the quality requirements of the separation section. | Blanking | A workable part is cut out of the sheet and the scrap is still on the sheet, usually to make a blank for further processing. |

| Piercing | Piercing is similar to blanking. But by contrast, the scrap is removed and what remains is the part. | |||

| Shearing | Shearing produces a straight line cut. Most commonly, it is used for parallel cuts, and angle cuts can be made as well. | |||

| Trimming | The perimeter edge of a form is cut away to conform with the desired profile. | |||

| 2 | Forming | The purpose of forming process is to make the plastic deformation of the sheet without breaking the metal stamping blanks and create metal stamping parts with required shape and size. . | Bending | The surface area of the blanks for metal stamping is stretched into an alternative shape by a controlled material flow. |

| Drawing | The material is deformed or bent along a straight line. | |||

| Stretching | The surface area of the blank is increased due to tension without inward movement of the blank edge. | |||

| Flanging | The material is bent along a curved line. | |||

| Reducing/Necking | It is used to reduce the diameter of the open end of a vessel or tube. | |||

| Curling | The material is deformed into a tubular profile. | |||

| Hemming | The edge is folded over onto itself to add thickness. | |||

| Embossing | The material is stretched into a shallow depression. | |||

| Coining | A pattern is compressed or squeezed into the material. | |||

| Ironing | The material is squeezed along a vertical wall to reduce in thickness. | |||

Metal stamping advantage

- Stamping processing has high production efficiency,easy operation, and easy implementation of mechanization and automation.

- Stamping dies ensure the dimensional and shape accuracy of the stamped parts with long life service. The stamping parts are almost identical with stable quality and good interchangeability.

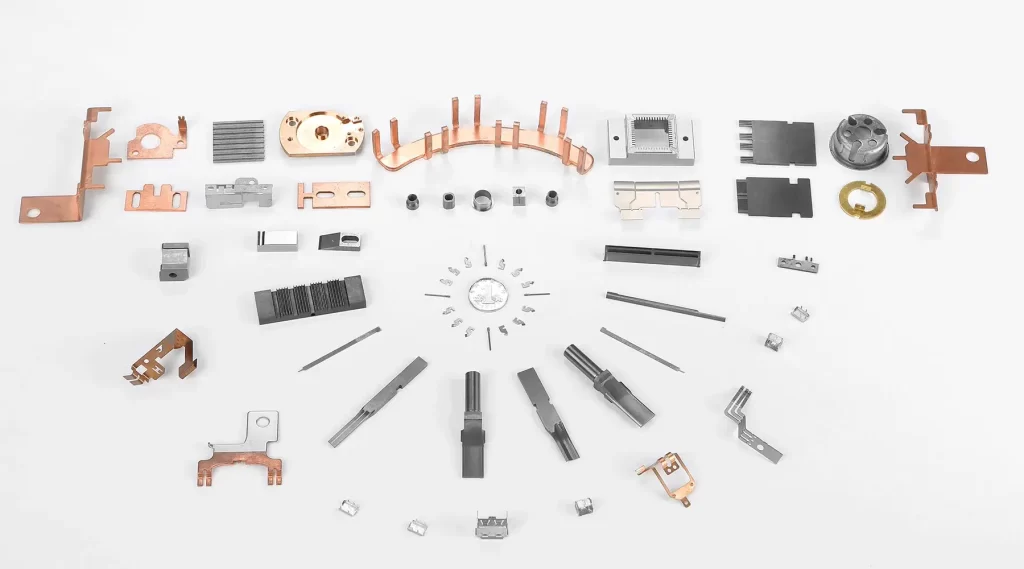

- Due to the high strength and high stiffness, stamping can process a large range of sizes and complex shapes, for example, as small as terminal and as large as automobile girder.

- Stamping usually does not generate scraps and required heating equipment, so it is a material saving and energy saving processing.

conclusion

Metal stamping can be applied to a variety of materials because of their unique metalworking quality for a number of applications in all walks of life, such as aerospace metal stamping parts, machinery parts, electronics parts, medical equipment parts, daily appliances products, lock hardware products, and so on. Metal stamping is not only used by the entire industry, but everyone is directly related to metal stamping parts. There are many large, medium and small stamping parts on airplanes, trains, and cars. The car body, frame and rims and other parts are all the automotive metal stamping parts.