What are the Different Types of Stamping Dies?

What is a stamping die?

Stamping die is a special machine tool used in manufacturing industries to cut and/or form material (metal or non-metal) to a desired parts or profile. It is a cold forming process, in which heat is neither used on purpose into the die nor the material, so also called cold stamping die.

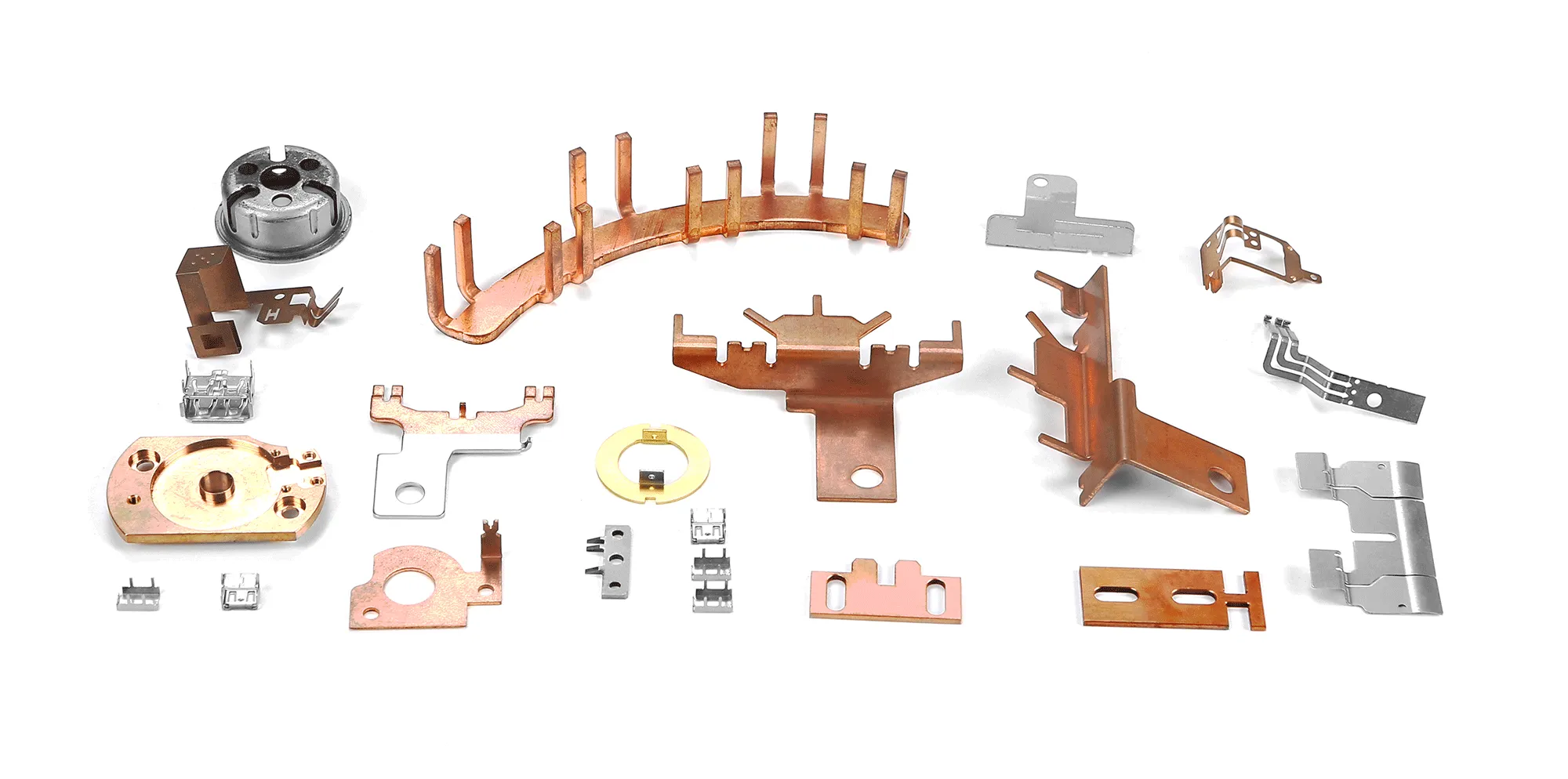

A stamping die is able to quickly process high-volume runs, crafting consistent and precise metal components at minimal expense. The parts produced can be exceptionally small or extremely large depending on the application. So they can be used for projects ranging from microelectronics to aerospace components.

What are the different types of stamping dies?

The types of metal die stamping techniques have diversified over the years to meet the demands of ever-changing markets. They are mainly classified into two groups according to the degree of process combination:

1.Multi-station stamping dies, in which a part is produced by moving the material through different stations.

2.Single-station stamping dies, also known as single-stage stamping dies or single-operation stamping dies, in which a single component is created or a single operation is performed by each stamping press.

As seen the following finger for clearer information:

| Types of Stamping Dies | ||||

| Process | classification | Type | definition | Applications |

| Stamping Dies | Multi-station Stamping Dies | Progressive Stamping Dies | Progressive die stamping, also referred to as follow-on die, has a series of operations within a single machine. Each station in the die performs a specific task under the press. After the task is completed, the workpiece is automatically moved to the next station. Once the part is finished, it is finally separated from the material or metal strip. | Progressive die stamping process gradually performs forming and cutting to get the desired components, which are better suitable for small components (e.g., terminal connectors, USB connector, etc. |

| Transfer Stamping Dies | Transfer die stamping process is similar to progressive die stamping process. But the part is free of the metal strip when they are fed into stamping stations in a transfer die stamping process. Components are produced by passing the workpiece through a series of consecutive station within a single die. And transfer die stamping may occur across multiple pressed or using a single press. | Transfer die stamping is Better suited for components are large and complex (e.g., frames, shells, tubes, and other structural components and systems). | ||

| Single-station Stamping Dies | Simple Stamping Dies | Simple dies or single actions perform one operation per stroke of the press. The operation may be one of the operation under cutting or forming dies. | Simple dies are ideal for basic operation, like blanking or piercing, but are not suited for large applications. | |

| Compound Stamping Dies | Compound dies are designed to perform two or more operations in a single stroke of the die press. | Compound dies are an excellent choice for complex or demanding piece than simple stamping dies. For example, a washer is produced by simulation blanking and piercing operations. But they are not ideal for forming operations (e.g., bending or drawing). | ||

| Combination Stamping Dies | Combination dies are similar to compound dies. They can perform more than one operation at one station. | Combination dies are suitable for both cutting and forming operations, meaning they can be used for blanking, piercing, bending, drawing, and so on. | ||

We offer metal stamping die design, custom metal stamping dies, stamping die components suitable for many applications. Our high quality dies ensure that our customers’ components meet their exact specifications. We specialize in progressive stamping and fabrication, allowing for a rapid rate of production for all stamped metal parts. For other services, please browse our website: www.uneedprecisionmachine.com.

Contact us (E-mail: info@uneedpm.com), your need, we meet!