From 1 piece to mass production, our one-stop custom services ensure a worry-free experience for you.

Help Center

Views: 222 Author: Rebecca Publish Time: 2025-12-31 Origin: Site

Content Menu

● 3-Axis vs 4-Axis vs 5-Axis CNC

>> Key Differences Between Machine Types

● Core Advantages of 5-Axis CNC Milling

>> High Precision and Surface Quality

>> Efficiency and Shorter Lead Times

>> Capability for Complex Geometry

>> Cost Effectiveness Over the Project Lifecycle

>> Improved Tooling Dynamics and Tool Life

● Typical Applications of 5-Axis CNC Milling

>> Industrial and Engineering Components

>> Medical and Healthcare Products

>> Creative and Architectural Work

● Materials Suitable for 5-Axis CNC Machining

>> Metals

>> Plastics

>> Composites

● From CAD Model to Finished 5-Axis Part

>> Standard 5-Axis Machining Workflow

● When to Choose 5-Axis CNC Machining

● UX and Visual Content Suggestions

● Targeted Call to Action: Partner With U-NEED

● FAQs About 5-Axis CNC Milling

>> Q1. What are the 5 axes in a 5-axis CNC machine

>> Q2. Is 5-axis CNC always better than 3-axis machining

>> Q3. Does 5-axis machining improve dimensional accuracy

>> Q4. Which industries benefit most from 5-axis CNC milling

>> Q5. What information should be prepared before requesting a 5-axis CNC quote

If you are looking for 5-axis CNC milling services to produce complex, tight-tolerance parts, this guide explains what 5-axis machining is, how it works, which materials it supports, and when it outperforms 3-axis or 4-axis machining. It is written for engineers, buyers, and product owners who need reliable information to choose the right manufacturing partner and process.

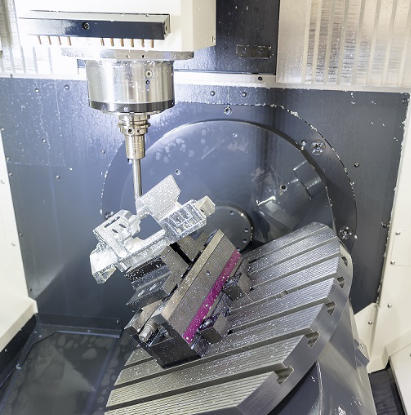

5-axis CNC milling is a subtractive manufacturing process where the cutting tool moves along three linear axes, X, Y, and Z, and also rotates around two additional axes, commonly A and B, to machine complex 3D geometries in a single setup. This extra rotational freedom allows the tool to reach almost any surface of the workpiece without manual re-clamping, improving accuracy and consistency.

In real production environments, 5-axis machines are widely used in aerospace, automotive, medical, mold-making, energy, and precision industrial components where both tight tolerances and high-quality surface finishes are critical. Because the tool can tilt and rotate, designers gain more freedom to create organic curves, deep cavities, and undercuts that are difficult or impossible to machine with traditional setups.

When engineers talk about 5-axis machining, they are describing how many directions the tool or workpiece can move relative to each other.

- X-axis: Left–right linear movement

- Y-axis: Front–back linear movement

- Z-axis: Up–down linear movement

- A-axis: Rotation around the X-axis

- B-axis: Rotation around the Y-axis

In typical configurations, A and B axes allow the spindle or table to tilt and rotate so the cutter can approach the part from inclined angles. As a result, one continuous toolpath can machine multiple faces and features of a part in a single program, which sharply reduces fixturing complexity and setup time.

For manufacturers and buyers, this translates into fewer setups, fewer accumulated errors, and higher repeatability across prototype and production runs.

To quickly select the right process level for a new part, it is useful to compare 3-axis, 4-axis, and 5-axis milling.

| Machine type | Axes of motion | Typical use cases | Main advantages | Main limitations |

|---|---|---|---|---|

| 3-axis CNC milling | X, Y, Z linear | Simple prismatic parts, plates, basic housings | Lower cost, simple programming, wide availability | Limited access to complex or inclined surfaces, more setups needed |

| 4-axis CNC milling | X, Y, Z plus one rotary axis | Shafts, rotors, parts requiring indexing around one axis | Better for round parts and indexed features, fewer re-clamps | Restricted for highly organic or multi-angle surfaces |

| 5-axis CNC milling | X, Y, Z plus two rotary axes | Complex aerospace, medical, mold, and precision components | One-setup machining, best access to complex geometry, high accuracy potential | Higher machine and programming cost, requires skilled process control |

For parts with multiple angled faces, deep pockets, or freeform shapes, 5-axis CNC is usually the most efficient and robust choice, especially when dimensional relationships between faces are critical.

A modern 5-axis CNC mill goes far beyond a basic 3-axis machine. It changes what can be made, how efficiently it can be produced, and how stable the quality remains over time.

Because a 5-axis machine can finish several faces of a part in a single setup, tolerances remain tight and alignment errors are minimized. Toolpaths can maintain more optimal engagement angles, which improves dimensional stability.

This also translates into smoother as-milled surfaces, less hand finishing, and more consistent performance for sealing surfaces, mating interfaces, and high-speed rotating components.

- Fewer setups and fewer fixtures

- Reduced manual handling and re-clamping

- Potentially fewer tool changes per operation

- Shorter overall cycle times on complex parts

A job that might require multiple separate setups on a standard mill can often be completed in a single continuous process on a 5-axis machine, significantly reducing labor, queue time, and total lead time.

Turbine blades, impellers, orthopedic implants, and advanced molds all contain twisted surfaces and varying angles that are difficult to machine with limited motion. With 5-axis control, these shapes can be approached directly, often using smooth, flowing toolpaths rather than segmented approximations.

For engineers, this enables design for function, with less compromise driven purely by machining constraints.

While 5-axis equipment is more expensive than basic machining centers, it often delivers a lower total cost per part when the entire workflow is considered:

- Reduced fixturing costs

- Lower scrap and rework rates

- Fewer separate operations

- Shorter lead times for high-value parts

For short or medium production runs in aerospace, medical, high-end automotive, and precision mechanical assemblies, 5-axis machining frequently proves more economical than multi-step 3-axis routes.

By tilting the tool, programmers can maintain more favorable cutting angles, reduce chatter, and control tool engagement. This supports the use of shorter, more rigid cutters and helps extend tool life while preserving surface quality.

Optimized 5-axis toolpaths also help distribute wear more evenly along the cutting edge, improving process stability in demanding materials such as stainless steel, titanium, and superalloys.

Because 5-axis milling can reach intricate undercuts, organic surfaces, and steep features, designers can focus on performance, weight reduction, and assembly simplification instead of being constrained by straight-line machining.

This is especially important in lightweight structures, ergonomic products, and medically customized components where shape is closely tied to function.

The versatility of 5-axis CNC machining makes it suitable for a wide range of industries and component types.

- Structural and functional parts for aerospace and automotive

- High-precision housings, brackets, and frames

- Complex manifolds and fluid-handling components

These applications depend on stable tolerances, consistent surface quality, and reliable relationships between features located on different faces.

- Custom implants and prosthetic components

- Surgical instruments and guides

- Dental components and fixtures

These products often include small radii, organic shapes, and tight tolerance requirements, making 5-axis machining a natural fit.

- Injection molds for plastic parts

- Die casting molds and cores

- Precision fixtures and jigs

Multi-axis motion allows faster and more accurate machining of complex cavities, cooling channels, and contoured surfaces, reducing both lead time and polishing effort.

- Sculptures and artistic installations

- Architectural features and decorative elements

- Functional prototypes for design validation

With 5-axis capabilities, intricate 3D forms can be translated directly from CAD or scanned data into physical parts in metals, plastics, or composites.

One of the strengths of 5-axis CNC milling services is compatibility with a broad range of materials, from softer plastics to advanced high-temperature alloys.

- Aluminum: Combines excellent machinability with a strong strength-to-weight ratio, ideal for housings, brackets, and structural components in automotive and aerospace.

- Stainless steel: Offers corrosion resistance and strength for food processing, medical tools, and structural hardware, though it requires optimized cutting conditions.

- Titanium: Provides high strength, low weight, and biocompatibility, commonly used in aerospace hardware and medical implants.

- Inconel and other superalloys: Designed for extreme temperatures and high stress, often found in turbine parts, exhaust systems, and high-performance engine components.

- Acrylic (PMMA): Used for optical components, display covers, and transparent enclosures due to its clarity and ease of machining.

- Nylon: A tough, wear-resistant material suitable for gears, bushings, and moving mechanisms.

- Polycarbonate: High impact resistance and strength make it ideal for protective covers, lenses, and structural plastic parts.

- CFRP (carbon fiber reinforced polymer): Lightweight and stiff, widely used in aerospace, motorsport, and high-performance consumer products.

- GFRP (glass fiber reinforced polymer): Common in marine, wind-energy, and construction applications where corrosion resistance is critical.

- Ceramics: Selected for heat-resistant and wear-resistant components in specialized industrial and medical systems.

- Graphite: Used where electrical and thermal conductivity are important, such as electrodes and heat management parts.

For each material, correct selection of tooling, fixturing, and cutting parameters is essential to balance surface finish, dimensional accuracy, and cycle time.

Understanding the typical workflow helps project owners plan timelines and communicate expectations clearly.

1. CAD preparation and design review

A 3D CAD model and supporting drawings are prepared, including key tolerances, material selection, and any surface treatment demands. An experienced manufacturing team reviews the design for machinability and may suggest adjustments to improve cost or robustness.

2. CAM programming and simulation

CAM software is used to create 5-axis toolpaths, define tools, feeds, and speeds, and run simulations to avoid collisions. At this stage, programmers fine-tune tilt angles and stepovers to achieve the required finish and cycle time.

3. Fixturing and machine setup

Fixtures are designed to hold the workpiece securely while allowing full tool access. On 5-axis machines, workholding can often be simplified compared to multi-setup 3-axis workflows.

4. Machining and in-process checks

The program is run on the machine, sometimes with in-process probing to confirm critical dimensions. For high-value parts, intermediate measurements help maintain stability and detect issues early.

5. Finishing and final inspection

After machining, deburring, polishing, and surface treatments are carried out if required. Final inspection then verifies tolerances, surface quality, and functional features before shipment.

Clear communication on critical dimensions, tolerance priorities, and inspection standards at the quotation stage helps ensure that the final parts match functional needs and assembly conditions.

Not every part requires a 5-axis solution, but certain situations strongly favor it.

- Parts with multiple angled faces or significant curvature

- Components that require tight tolerances across features located on different sides

- Projects using expensive materials where scrap risk must be minimized

- Applications where smoother as-milled surfaces reduce or eliminate secondary processes

- Situations where reducing lead time and handling is critical for launch schedules

For simpler prismatic components with easily accessible surfaces, a 3-axis solution can still be very efficient and cost-effective. Many manufacturers combine 3-axis, 4-axis, and 5-axis capacity, assigning each part to the most economical process based on geometry and tolerance.

To improve readability and engagement, the following visual elements are recommended:

- Early in the article, add a labeled diagram or short animation of a 5-axis CNC machine showing X, Y, Z, A, and B motion.

- In the advantages section, use a simple chart or graphic comparing cycle time and setups between 3-axis and 5-axis machining for a sample part.

- In the materials section, include icons or a grid visual for metals, plastics, composites, and advanced materials.

- In the workflow section, insert a process flow graphic that summarizes CAD → CAM → machining → finishing and inspection.

These visuals help both technical and non-technical readers quickly understand key concepts and stay focused on the content.

If your next project involves complex geometry, tight tolerances, or a mix of materials such as metals, plastics, silicone, and stamped metal parts, choosing an experienced OEM manufacturing partner is essential. A single integrated supplier can help consolidate your 5-axis CNC machining, high-precision mechanical parts, plastic product manufacturing, silicone product manufacturing, and metal stamping into one coordinated supply chain.

U-NEED focuses on supporting overseas brands, wholesalers, and manufacturers with flexible OEM services, from initial prototyping to stable batch production. To move your project forward:

- Prepare your 3D CAD files and 2D drawings with key tolerances.

- Indicate target materials, quantities, and any special inspection requirements.

- Share performance goals, budget range, and expected timeline.

Send your project details to U-NEED today to receive a tailored 5-axis CNC machining and OEM manufacturing solution, and turn your design into a production-ready, high-precision part with reliable lead times and consistent quality.

The five axes are three linear motions, X, Y, and Z, plus two rotational motions, often labeled A and B. Together they allow the cutting tool or table to tilt and rotate so that multiple surfaces of a part can be machined in a single setup with improved access and accuracy.

No. For simple prismatic parts with easily accessible features, 3-axis machining can be faster and more economical. 5-axis machining becomes more advantageous when the part includes complex curves, steep surfaces, or multiple angled faces that would otherwise require several setups and fixtures.

In many cases it does. Because fewer setups and re-clamping operations are needed, there are fewer opportunities for positioning errors to accumulate. Combining this with optimized tool engagement and shorter tools often results in better dimensional stability and more consistent surface finishes.

Industries that use complex, high-value parts benefit most, including aerospace, medical, automotive, mold and die, energy, and high-end industrial equipment. These sectors often need precise geometries, tight tolerances, and reliable performance, making multi-axis machining an important capability.

It is helpful to prepare 3D CAD models, 2D drawings with critical tolerances, material specifications, surface finish requirements, estimated quantities, and any special inspection standards. Providing complete technical information allows manufacturers to estimate cost, lead time, and suitable machining strategies more accurately.