From 1 piece to mass production, our one-stop custom services ensure a worry-free experience for you.

Help Center

Views: 222 Author: Rebecca Publish Time: 2026-01-15 Origin: Site

Content Menu

● What Are 3D Printed Threads?

● Thread Terminology and Standards

● Choosing the Right 3D Printing Technology

● Design Rules for 3D Printed Threads

● Printing External Threads: Step-by-Step

● Printing Internal Threads: Step-by-Step

● Critical Slicer Settings for Thread Quality

● Strength, Tolerance, and Longevity Considerations

● Advanced Methods: Inserts, Tapping, and Hybrid Approaches

● 3D Printed Threads vs Other Fastening Methods

● Step-By-Step Workflow: From CAD to Production

● Partner With a Professional OEM Manufacturer

● FAQs About 3D Printing Threads

>> 1. What is the best thread size to 3D print?

>> 2. Can small fine-pitch threads be 3D printed?

>> 3. How do I stop 3D printed threads from being too tight?

>> 4. Are printed threads strong enough for metal screws?

>> 5. Should I print threads horizontally or vertically?

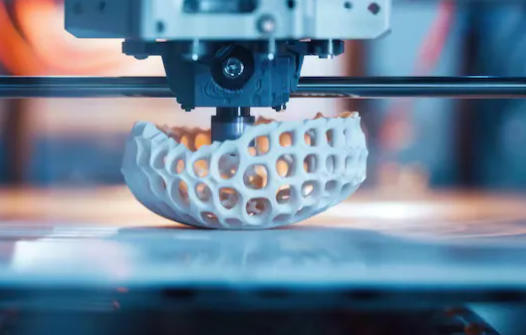

3D printing threads turns simple plastic or metal parts into functional fasteners, enclosures, and assemblies, but getting clean, reliable screw connections requires the right design strategy, printer settings, and post-processing approach. This enhanced guide walks through thread types, key design rules, printing parameters, and advanced methods like inserts and hybrid manufacturing so engineers and product developers can confidently move from prototype to production-grade threaded parts.

3D printed threads are helical grooves or ridges (internal or external) created directly in a printed part so it can fasten, align, or connect to another component. They can be printed in plastics or metals and used either as stand-alone fasteners or as integrated features in housings, fixtures, and mechanical systems.

- Internal (female) threads are printed inside holes or bosses.

- External (male) threads are printed on shafts, studs, or caps.

- Threads may follow standard profiles (ISO metric, UNC/UNF, NPT) or be custom-designed for specific applications.

Compared with traditional machining, 3D printing allows complex thread geometries, custom diameters, and integrated features in a single build, reducing assembly steps and tooling costs.

3D printing threads is attractive when designers need fast iteration, custom sizes, or integrated fastening without secondary hardware. However, thread quality depends strongly on the printing technology, material, and design choices.

Key benefits include:

- Rapid prototyping of threaded assemblies without machining.

- Custom diameters and pitches that match unique product requirements.

- Integrated fasteners that reduce part count and simplify assembly.

- Ability to test fit, ergonomics, and pre-production concepts before committing to tooling.

Typical use cases:

- Enclosures and lids with screw caps or bayonet-style threads.

- Robotics and automation fixtures needing adjustable, reconfigurable joints.

- Consumer products with custom knobs, bottle caps, or camera mounts.

- Industrial jigs and fixtures where complex threads would be difficult to machine.

Using correct thread terminology helps ensure compatibility and predictable performance, especially when your printed parts must mate with off-the-shelf fasteners.

Core terms:

- Major diameter: The outside diameter of an external thread or inside diameter of an internal thread.

- Minor diameter: The root diameter of the thread.

- Pitch: Distance from one thread crest to the next, measured parallel to the axis.

- Thread profile: Shape of the thread (triangular, trapezoidal, rounded, custom).

Common standards:

- ISO metric (M) threads for most global applications.

- UNC/UNF (Unified) threads for many North American products.

- NPT/BSP pipe threads for fluid and pneumatic connections.

For most FDM and SLA printers, using larger thread sizes such as M6 or 1/4"-20 and above significantly improves printability and durability.

Different printing processes produce very different thread quality, tolerance, and strength. Matching the technology to your requirements is crucial.

- FDM (Fused Deposition Modeling): Best for low-cost prototypes and large plastic threads; resolution limits make very fine threads difficult.

- SLA/DLP (resin): High resolution and smooth surfaces suitable for fine, detailed threads, but brittle resins may limit load-bearing capacity.

- SLS (nylon powder): Good balance of strength and resolution with no support structures, ideal for functional plastic threaded components.

- Metal AM (SLM/DED): Suitable for high-strength metal threads; fine threads often require post-machining for optimal tolerance.

Where high mechanical loads or tight tolerances are critical, combining printed geometry with inserts or post-machining often yields more reliable results than relying solely on as-printed threads.

Designing threads specifically for additive manufacturing reduces print failures, friction, and premature wear.

Basic dimensional guidelines:

- Use minimum external diameters around 3–4 mm for FDM and larger when possible.

- Keep pitch at or above about 0.8 mm for FDM to avoid merging adjacent thread profiles.

- Avoid very small screws (below about M5) on FDM; resolve them on SLA or SLS instead.

For internal threads:

- Add clearance by increasing hole diameter slightly to ensure a sliding fit.

- Account for hole shrinkage by modeling holes slightly larger than the target size.

For wall thickness and strength:

- Use at least two to three perimeters for plastic threads to prevent stripping.

- For heavily loaded threads, increase perimeter count to three or more and infill to 50–100 percent.

These guidelines help ensure threads are robust enough for repeated tightening while remaining printable on common desktop and industrial machines.

Most modern CAD tools provide threading features that make designing printable threads straightforward. Popular CAD tools include Fusion 360, SolidWorks, Onshape, and similar platforms.

Best practices:

- Use modeled threads (true 3D geometry) instead of cosmetic threads when you plan to 3D print them.

- Design threads as parametric features so pitch, diameter, and length can be adjusted quickly.

- When possible, simplify the profile (slightly rounded or truncated crests and roots) to improve printability and reduce sharp stress risers.

For external threads, draw a cylinder at the major diameter, extrude to length, then apply the thread feature with the required pitch and fit class. For internal threads, create a hole at the major diameter, then apply an internal thread feature to the surface.

External threads are generally easier to print and more tolerant of minor dimensional errors.

Typical workflow:

1. Model a cylinder with the desired major diameter and length.

2. Apply a thread feature using a standard such as ISO metric and choose a coarse pitch where possible.

3. Orient the part so the threaded axle stands vertically on the build plate.

4. Set a fine layer height, for example 0.1–0.2 mm for FDM or 0.05 mm or less for SLA.

5. Use at least three perimeter walls and adequate infill to support the thread roots.

6. Print a short test bolt first to validate fit before running full production batches.

Vertical orientation aligns the thread cross-section with the XY plane, where most printers deliver the best dimensional accuracy and surface detail.

Internal threads are more sensitive to over-extrusion, support placement, and hole shrinkage.

General steps:

1. Design the hole at the nominal major diameter of the target thread, then increase slightly for clearance.

2. Apply an internal thread feature in CAD, using a realistic pitch and simplified profile.

3. Orient the threaded hole vertically to avoid sagging in the thread peaks.

4. Avoid supports inside threads; redesign overhangs or split the part if necessary.

5. Print with low layer height and a well-calibrated extrusion multiplier.

6. Post-process by chasing the thread with a tap or lightly sanding to improve smooth engagement.

For small internal diameters, designers often rely on tapping or threaded inserts rather than fully printed internal threads, especially for high-load or high-cycle applications.

Even a perfect CAD model will fail if slicer settings are not optimized for thread detail and tolerance.

Important parameters:

- Layer height: Use low values (around 0.1–0.2 mm for FDM) to resolve fine thread features.

- Print speed: Reduce speed on threaded regions to improve accuracy and surface finish.

- Extrusion multiplier or flow: Slightly reduce flow to avoid over-extruded, tight-fitting threads.

- Temperature: Tune nozzle temperature per filament to ensure strong layer bonding without excessive stringing or bulging.

- Infill density: For load-bearing threaded zones, infill of at least 25–50 percent is recommended, with higher values for structural parts.

Many engineers create specialized slicer profiles dedicated to threaded parts, using slower speeds and finer layers only where needed.

3D printed threads experience cyclic loading, friction, and torsion, so strength and durability must be considered early in design.

To improve strength:

- Choose durable materials such as PETG, nylon, or reinforced composites for functional fasteners.

- Increase root radius and avoid sharp corners to reduce stress concentrations.

- Use fillets or chamfers at the start of threads to reduce cross-section shock.

To manage tolerance and wear:

- Design with an intentional clearance offset between mating threads.

- Test fit early and iterate CAD dimensions based on measurement of actual printed parts.

- Consider rounded or semi-circular thread profiles on plastics to distribute contact and reduce wear.

For high-duty cycles, metal inserts or post-machined threads typically offer better long-term performance than purely printed threads in plastics.

When thread precision or load requirements exceed what is practical with direct printing, combining mechanical methods with 3D printed geometry delivers robust results.

Common techniques:

- Heat-set threaded inserts: Brass inserts pressed into 3D printed bosses using heat, creating strong, reusable threads in plastics.

- Ultrasonic inserts: Installed with vibration, suitable for production environments.

- Drilling and tapping: Print a pilot hole, then use conventional taps to cut precise threads.

- Embedded nuts and studs: Pause the print, drop hardware into cavities, and resume to lock metal threads inside the part.

These hybrid methods are widely used in production-grade enclosures and mechanical assemblies where reliability and serviceability matter.

Across industries, 3D printed threads support both rapid development and small-batch production.

Typical applications include:

- Consumer electronics: Device housings with threaded inserts for repeated screw assembly.

- Industrial tooling: Custom clamps and fixtures using large printed threads for adjustability.

- Medical devices and lab equipment: Custom connectors, sensor mounts, and fluid fittings.

- Metal components: Additively manufactured manifolds or brackets with post-machined threads to reduce overall machining time.

Service bureaus and contract manufacturers frequently combine 3D printing with CNC machining or stamping to deliver threaded metal parts that meet tight tolerance and strength requirements in demanding environments.

The table below compares direct 3D printed threads with common alternative fastening approaches.

| Fastening method | Typical use case | Pros | Cons |

|---|---|---|---|

| Direct printed plastic thread | Prototypes, light-duty assemblies | Fast, no extra hardware, highly customizable | Limited strength, wear over time, tolerance sensitive |

| Printed thread in resin | Fine mechanisms, small connectors | High detail, smooth surface | Brittle in many resins, load capacity limited |

| Heat-set threaded insert | Repeated assembly in plastic housings | Very strong, durable, easy to replace | Adds process steps and hardware cost |

| Drilled and tapped hole | High precision, moderate to high loads | Accurate, compatible with standard fasteners | Requires drilling or tapping tools and extra labor |

| Post-machined metal thread | Structural metal parts and harsh environments | Excellent strength and precision | Higher cost, needs CNC or manual machining |

For many OEM and industrial projects, a hybrid strategy that prints complex geometry and then adds inserts or tapped holes only where necessary balances cost, lead time, and performance.

The following end-to-end workflow helps standardize how engineering teams design and validate 3D printed threads.

1. Define requirements:

- Load, environment, cycle life, compatible hardware, target printing technology.

2. Select thread standard and size:

- Choose ISO or UNC thread at or above M6 or 1/4"-20 for general FDM parts.

3. Model threads in CAD:

- Use parametric features and add appropriate clearance and fillets.

4. Prepare slicer settings:

- Fine layer height, reduced speed, tuned extrusion, and sufficient infill.

5. Print test coupons:

- Short male and female thread samples to validate tolerance and fit.

6. Post-process:

- Remove supports, lightly deburr, optionally tap or add inserts.

7. Scale to production:

- Lock in validated parameters and document them as part of your manufacturing instructions.

Following a repeatable process reduces risk and builds organizational knowledge around threaded additive manufacturing.

When threaded parts move from internal prototypes to customer-facing products, working with an experienced manufacturing partner reduces failure risk and total cost. A high-precision OEM provider specializing in machining, plastic molding, silicone parts, metal stamping, and 3D printing can validate designs, recommend better thread strategies, and combine additive with CNC or inserts where needed.

If you are planning a new threaded assembly or need to industrialize existing 3D printed threads, consider collaborating with a full-service supplier that can review your CAD models, optimize thread design for your application, and deliver reliable parts from prototype to mass production. To get started quickly, send your threaded part drawings, material requirements, and target quantities for a detailed manufacturability review and a tailored quotation.

Threads at or above M6 or 1/4"-20 are usually the most reliable on common FDM machines, because they offer enough feature size for accurate layers and robust strength. Smaller threads can work on higher-resolution technologies but are more sensitive to calibration.

Very fine threads can be printed using high-resolution technologies like SLA or SLS, but they may still require post-processing and are more fragile than larger coarse-pitch threads. Designers often limit fine threads to low-load or adjustment-only applications.

Increase clearance in CAD by a small amount, for example 0.1–0.2 mm on the nominal diameter, and slightly reduce the extrusion multiplier. It also helps to calibrate temperature and flow so that perimeters are not over-extruded, which can make threads bind.

Printed plastic threads can handle light to moderate loads, but for repeated assembly with metal screws or higher torque, heat-set inserts or tapped metal threads are strongly recommended. This approach prevents stripping and maintains long-term reliability.

Vertical orientation usually gives better thread definition and strength because layers stack along the thread axis and the XY plane provides the best dimensional accuracy. Horizontal threads are more prone to stair-stepping effects and may require more post-processing.

1. https://www.rapiddirect.com/blog/3d-printing-threads/ [snapmaker](https://www.snapmaker.com/blog/3d-printing-threads/)

2. https://www.unionfab.com/blog/2024/10/3d-printing-threads [youtube](https://www.youtube.com/watch?v=JIMfW6bMgE0)

3. https://formlabs.com/global/blog/adding-screw-threads-3d-printed-parts/ [kingroon](https://kingroon.com/blogs/3d-printing-guides/how-to-3d-printing-threads-perfectly)

4. https://kingroon.com/blogs/3d-printing-guides/how-to-3d-printing-threads-perfectly [unionfab](https://www.unionfab.com/blog/2024/10/3d-printing-threads)

5. https://jlc3dp.com/blog/considerations-for-3d-printing-threads [kingroon](https://kingroon.com/en-germany/blogs/3d-printing-guides/how-to-3d-printing-threads-perfectly)