From 1 piece to mass production, our one-stop custom services ensure a worry-free experience for you.

Help Center

Views: 222 Author: Rebecca Publish Time: 2026-01-14 Origin: Site

Content Menu

● What Is CNC Machining for Metal Parts?

>> Core CNC Processes Used in Metal Part Production

● Why CNC Machining Is Ideal for Metal Parts Manufacturing

>> Key Benefits for OEM Buyers

● Common Metals for CNC Machined Parts

>> Overview of Popular CNC Metals

● Typical CNC Machining Tolerances and Surface Requirements

>> Practical Tolerance Guidelines

● From Prototype to Mass Production with CNC Machining

>> Rapid Prototyping for Design Validation

>> Scaling Up to Volume Production

● Latest Trends in CNC Machining for Metal Parts

>> Multi-Material and Hybrid Components

>> IoT, AI, and Smart Factories

>> On-Demand and Distributed Production

● How to Design Metal Parts for CNC Machining

>> Practical DFM Tips for CNC Parts

● Key Selection Criteria for a CNC Machining Supplier

>> What to Check Before You Place an Order

● Case Example: How an Integrated Supplier Supports OEM Metal Parts Projects

>> Typical Multi-Process OEM Scenario

● How to Work Effectively with a CNC Machining Partner

>> Practical Collaboration Checklist

● Take the Next Step with a Professional CNC OEM Partner

● FAQs About CNC Machining for Metal Parts Manufacturing

>> Q1: What is the main advantage of CNC machining over traditional manual machining?

>> Q2: Which metals are most commonly used for CNC machined parts?

>> Q3: Can CNC machining handle both low-volume prototypes and high-volume production?

>> Q4: How tight can CNC machining tolerances be?

>> Q5: How is CNC machining evolving with Industry 4.0?

CNC machining for metal parts manufacturing is a subtractive process where computer-controlled cutting tools remove material from a solid metal billet to create precise components. This guide explains how CNC machining supports custom metal parts for global OEMs, wholesalers, and brand owners, and how an integrated supplier can help reduce risk and cost across the entire product lifecycle.

CNC (Computer Numerical Control) machining uses programmed toolpaths to automatically cut, drill, and shape metal workpieces into finished parts with repeatable accuracy. Because the machines follow digital instructions instead of manual handwheels, they can hold tighter tolerances and deliver far higher consistency than traditional machining.

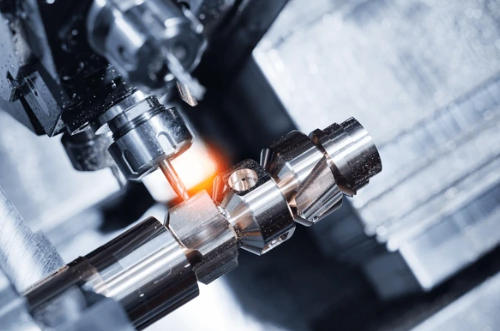

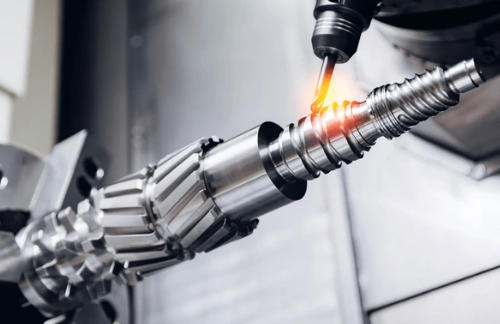

Different CNC processes are combined to meet dimensional, surface, and cost requirements in OEM projects. The most common include:

- CNC milling: Rotating cutting tools remove material to create planes, pockets, slots, and complex 3D surfaces for housings, brackets, and structural parts.

- CNC turning: A rotating bar or billet is cut with fixed tools to form shafts, bushings, sleeves, and other cylindrical parts.

- 5-axis CNC machining: Simultaneous motion on five axes allows machining of complex geometries in a single setup for aerospace, medical, and precision robotics components.

- Swiss machining: Long, slender parts such as pins, medical components, and precision fasteners are produced with high efficiency and accuracy.

- Wire EDM and CNC grinding: Used for very hard metals and ultra-tight tolerance features, especially in molds, dies, and bearing surfaces.

CNC machining delivers a combination of precision, flexibility, and speed that is difficult to match with other metal manufacturing processes. This makes it especially attractive for OEMs needing mixed volumes, frequent design changes, or complex geometries.

- High precision and tight tolerances: CNC machines can achieve consistently accurate parts, enabling fits in demanding applications like automotive and medical devices.

- Excellent repeatability: Once a program and setup are validated, the same part can be reproduced thousands of times with minimal variation, which is critical for brand quality.

- Complex geometries: Multi-axis machining unlocks undercuts, free-form surfaces, and integrated features that are difficult or impossible with manual machining.

- Faster lead times: Automated toolpaths, optimized cutting speeds, and 24/7 machine operation shorten production and delivery times.

- Lower material waste: Optimized toolpaths and consistent cutting reduce scrap, improving cost efficiency on expensive metals.

- Improved safety: Operators interact mostly with enclosed, automated equipment, reducing exposure to cutting tools and chips.

Choosing the right metal is one of the most important engineering and sourcing decisions in CNC machining projects. The material directly affects strength, weight, corrosion resistance, machinability, and total cost.

| Metal | Key properties and use cases |

|---|---|

| Aluminum | Lightweight, good strength-to-weight ratio, excellent machinability; ideal for enclosures and structural parts. |

| Stainless steel | High corrosion resistance and durability; widely used in medical, food, and outdoor applications. |

| Carbon steel | Strong, cost-effective, suitable for structural and mechanical parts requiring high strength. |

| Titanium | Exceptional strength-to-weight and corrosion resistance; used in aerospace, medical, and high-performance parts. |

| Brass / copper | Good conductivity and machinability; preferred for electrical, plumbing, and decorative components. |

When sourcing, buyers should balance performance needs with machining cost, surface finish requirements, and downstream operations such as plating or coating.

CNC machining can routinely meet tight dimensional tolerances that many other metal processes cannot achieve. However, specifying unnecessarily tight tolerances may increase cycle time, scrap, and cost.

- Standard CNC tolerances often range around ±0.1 mm for non-critical features, with tighter values achievable on critical dimensions when needed.

- For small, precision parts, micrometer-level tolerances can be held with advanced machines and careful process control.

- Surface roughness requirements should be aligned with function; cosmetic or sealing surfaces may require finer finishing than internal or hidden features.

To optimize cost, OEMs should clearly mark critical dimensions on drawings and allow looser tolerances where possible.

CNC machining is extremely flexible across the product lifecycle, from early design validation to stable mass production. This makes it a strong fit for overseas OEMs who need both speed and scalability.

- CNC machines can quickly turn 3D CAD data into physical prototypes without the need for tooling, reducing time to market.

- Metal prototypes allow realistic testing of strength, assembly, and performance before committing to volume manufacturing.

- Iterations can be made fast: designers adjust the CAD model, and a new prototype can be machined within days.

- Once a program, fixtures, and process parameters are validated in prototyping, the same setup can be used for low, medium, or high-volume production.

- Automation, multi-axis equipment, and optimized toolpaths help keep cycle times short and unit costs competitive at scale.

- CNC machining can coexist with other processes; for example, it can be used for high-precision features after stamping, casting, or molding.

The CNC industry is evolving quickly, driven by Industry 4.0, smarter machines, and new material combinations. Understanding these trends helps buyers choose partners who are investing in the future.

Modern CNC machining increasingly supports hybrid designs that combine metals with composites or other materials. Such designs can lower weight while maintaining strength, stiffness, or corrosion resistance in critical zones.

- IoT-enabled CNC machines capture real-time data on spindle loads, temperatures, and cycle times, improving process visibility and preventive maintenance.

- AI and machine learning models are being used to optimize toolpaths, detect anomalies, and reduce downtime and scrap.

- For OEMs, this translates into more stable quality, predictable lead times, and better traceability across batches.

CNC machining is well suited to on-demand production models where parts are produced in smaller batches as needed rather than stored as large inventories. This can help brands respond to market changes, reduce stock risk, and localize production closer to end customers.

Thoughtful design can significantly improve manufacturability, reduce cost, and enhance reliability for CNC machined components. OEM engineers and buyers should coordinate early with their machining partners to optimize critical features.

1. Use consistent wall thicknesses where possible to reduce distortion and uneven cooling.

2. Avoid unnecessarily deep pockets; if required, consider increasing radius or splitting into multiple parts.

3. Select standard hole sizes that match common drill and reamer dimensions.

4. Add fillets instead of sharp internal corners to improve tool life and reduce stress concentration.

5. Only apply ultra-tight tolerances and special finishes to features that truly need them.

Providing clear 3D CAD files, 2D drawings with tolerance callouts, and information on functional surfaces will allow your supplier to quote accurately and suggest improvements.

For overseas OEMs, the quality and reliability of a CNC supplier directly affect product performance and brand reputation. Evaluating capabilities in a structured way reduces risk and speeds up project onboarding.

- Process scope: Can the supplier handle CNC machining, plastic molding, silicone parts, and metal stamping in-house to reduce your vendor base.

- Equipment and capacity: Types of machines (3-axis, 5-axis, turning centers, automation), shift patterns, and monthly output.

- Quality system: Use of incoming material inspection, in-process checks, final inspection, and traceable documentation.

- Engineering support: Ability to provide DFM feedback, tolerance optimization, and material selection advice.

- Logistics and service: Experience with export documentation, packaging standards, and global shipping.

Choosing a partner who understands both manufacturing and OEM-level requirements reduces communication friction and helps avoid costly redesigns later in the project.

An integrated contract manufacturer that offers CNC machining along with plastic and silicone production plus metal stamping can deliver significant advantages to overseas OEM buyers. By consolidating multiple processes under one roof, buyers can simplify supplier management and improve consistency across assemblies.

- Metal CNC parts: Precision housings, brackets, shafts, or heat sinks manufactured to tight tolerances.

- Plastic parts: Injection molded covers, knobs, and enclosures that must fit precisely with machined metal components.

- Silicone parts: Seals, gaskets, and shock-absorbing elements that interface with both plastic and metal parts.

- Metal stamping: High-volume sheet metal components such as brackets, terminals, and shields that are later finished by CNC where necessary.

With all these capabilities integrated into a single OEM partner, brand owners gain faster communication, shared engineering standards, and smoother assembly fit between different material components.

Strong collaboration between OEM engineering teams and the machining supplier is essential to achieve the best balance of quality, speed, and cost.

- Share 3D CAD models, 2D drawings, material specs, expected annual volume, and application details from the start.

- Request DFM feedback early to adjust geometries, tolerances, and surface finishes before final design freeze.

- Align on inspection plans, measurement methods, and sample approval criteria to avoid ambiguity in quality expectations.

- Discuss packaging, labeling, and logistics requirements to protect parts in transit and simplify your internal receiving process.

Clear, proactive communication helps your CNC partner deliver better parts and more accurate lead times, even when designs are complex or timelines are aggressive.

Choosing the right CNC machining partner for metal parts manufacturing is a strategic decision that affects cost, lead time, and product reliability. Partnering with an integrated OEM-focused factory that can also handle plastics, silicone products, and metal stamping simplifies your supply chain and improves long-term competitiveness.

If you are planning a new metal component or looking to optimize an existing one, contact our professional team now, share your drawings and requirements, and get a tailored CNC machining solution that matches your quality, budget, and delivery targets.

CNC machining provides higher accuracy, repeatability, and speed by using computer-controlled toolpaths rather than manual operations. This reduces human error and improves overall part consistency.

Aluminum, stainless steel, carbon steel, titanium, brass, and copper are widely used because they balance machinability, mechanical properties, and cost for different applications. Selection depends on strength, weight, corrosion resistance, and budget.

Yes, the same CNC programs and fixtures can be used from prototype through mass production, making it suitable for flexible volumes and design updates. Automation and multi-axis machines help keep unit costs competitive at higher volumes.

Standard tolerances are often around ±0.1 mm for non-critical features, but advanced machines and robust process control can achieve much tighter tolerances for critical dimensions when necessary.

Modern CNC machines integrate IoT, sensors, and AI to monitor performance in real time, optimize toolpaths, predict maintenance needs, and reduce downtime and scrap. These smart capabilities improve reliability and traceability for OEM buyers.

1. https://www.scan2cad.com/blog/cnc/cnc-machining-for-metal-fabrication/

2. https://www.fictiv.com/articles/metal-parts-manufacturing

3. https://www.rapid-protos.com/cnc-machining/metal/

4. https://www.xometry.com/resources/machining/cnc-machining-benefits/

5. https://www.bgmfg.com/advancements-and-trends-in-multi-axis-cnc-machining/

6. https://www.3erp.com/blog/future-of-cnc-machining/

7. https://www.hubs.com/cnc-machining/metal/

8. https://www.tfgusa.com/the-7-advantages-of-cnc-machining/

9. https://www.metalbook.com/blogs/what-makes-cnc-cutting-so-popular-in-metal-fabrication/

10. https://www.3erp.com/blog/advantages-of-cnc-machining-and-milling/