From 1 piece to mass production, our one-stop custom services ensure a worry-free experience for you.

Help Center

Views: 222 Author: Loretta Publish Time: 2025-12-26 Origin: Site

Content Menu

● What Is 3D Printing and Why It Matters

● Search Intent And Keyword Focus

● Early Foundations In The 1980s

>> 1980–1984: Early Rapid Prototyping Concepts

>> 1986–1988: Stereolithography And The First Commercial Printer

● Technology Diversification In The Late 1980s And 1990s

>> Color, Resolution, And Software Improvements

● Medical And Open-Source Breakthroughs In The 2000s

>> Medical Milestones And Bioprinting Concepts

>> The RepRap Project And Open-Source Expansion

● 2010s: From Novelty To Production-Ready Technology

>> 3D-Printed Vehicles And Aircraft

>> Multi-Material Printing And Higher Performance

● Recent 3D Printing Milestones: 2020s And Beyond

>> Industrialization And Production Integration

>> AI, Automation, And High Precision

● New Frontiers: Construction, Space, And Sustainability

>> Construction-Scale 3D Printing

>> Food Printing, Space Applications, And Resource Efficiency

● Key 3D Printing Milestones At A Glance

● How 3D Printing Fits Into Prototype-To-Production Workflows

● Practical Guide To Choosing A 3D Printing Process

● Hybrid Manufacturing: Combining 3D Printing With Traditional Processes

● FAQs About 3D Printing Milestones

>> 1. When was 3D printing invented?

>> 2. What is considered the biggest early milestone in 3D printing?

>> 3. How did open-source projects affect 3D printing?

>> 4. Is 3D printing used for final production parts today?

>> 5. What are the most important recent milestones in 3D printing?

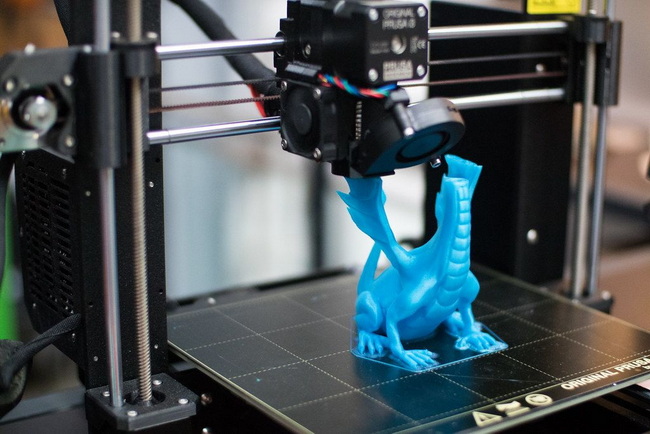

3D printing has evolved from experimental lab equipment in the 1980s into a strategic manufacturing technology that powers prototypes, end-use parts, and even life-saving medical devices today. This guide walks through the key milestones, shows how they shaped current capabilities, and looks ahead to where additive manufacturing is heading next.

3D printing, or additive manufacturing, builds parts layer by layer from digital 3D models rather than removing material from a solid block. This shift enables complex geometries, faster iteration, and localized production that traditional methods struggle to match.

Key benefits for engineers, OEMs, and product teams include:

- Rapid prototyping with shorter design–test–iterate cycles.

- On-demand production that reduces inventory and tooling costs.

- Lightweight designs that improve performance in aerospace, automotive, and consumer products.

- Customization for medical implants, dental parts, and wearables.

For manufacturers and OEM service partners, 3D printing now sits alongside CNC machining, injection molding, and metal fabrication as part of a flexible digital manufacturing toolkit.

To align with high-intent search queries, this article targets the primary keyword 3D printing milestones and related long-tail phrases such as “history of 3D printing,” “3D printing timeline,” “evolution of 3D printing,” “3D printing future trends,” and “additive manufacturing history.” These phrases are used naturally in headings, introductory paragraphs, and key sections.

Strategic placement of these keywords includes:

- Title with “3D Printing Milestones that Shaped the Past and Future.”

- H2 and H3 headings focused on historical phases, technologies, and future trends.

- Early paragraphs that clearly connect 3D printing milestones with real-world manufacturing impact.

Internal links to deep-dive resources, such as general 3D printing guides, process-specific pages, and prototyping-to-production case studies, further strengthen topical authority.

The story of 3D printing milestones begins with foundational experiments in photopolymerization and layer-based manufacturing during the early 1980s. These innovations established the core principle that 3D objects could be built up layer by layer from digital data.

In the early 1980s, researchers explored ultraviolet light to cure photosensitive resin layer by layer, creating the conceptual basis for modern stereolithography. Although early pioneers faced funding and patent challenges, their work is widely recognized as an essential milestone in the history of 3D printing.

These first systems were basic in capability, yet they demonstrated that physical parts could be created directly from 3D models without traditional tooling.

In the mid-1980s, stereolithography was patented and later commercialized through the release of the first SLA printer. This machine allowed industrial users to produce detailed plastic parts directly from CAD data.

The launch of this commercial printer marked a turning point, transforming 3D printing from research into an accessible industrial tool for rapid prototyping.

The next wave of 3D printing milestones focused on new processes and materials that broadened the scope of applications far beyond photopolymer resins.

Selective Laser Sintering, or SLS, introduced a powder-bed approach that fused powdered materials such as plastics and metals with a laser. This method produced strong, functional parts and opened the door to applications in aerospace, automotive, and industrial components.

Around the same period, Fused Deposition Modeling, often known as FDM, used thermoplastic filament extruded through a heated nozzle to build parts layer by layer. This technique eventually became one of the most widespread 3D printing technologies, especially for desktop and educational systems.

Together, SLS and FDM created two core families of 3D printing processes that are still widely used for prototypes and end-use parts.

During the 1990s, new processes allowed for color printing and finer surface details, broadening the aesthetic and functional possibilities. Advances in CAD software, file formats, and scanning technologies made 3D design more accessible and streamlined the workflow from digital model to printed part.

This is an effective place in the article to insert a visual timeline graphic covering 1980–2000 milestones, helping readers quickly understand the progression.

In the 2000s, 3D printing began shifting from purely industrial prototyping toward open-source innovation and medical breakthroughs that highlighted its impact on human health and accessibility.

Around the turn of the millennium, researchers produced 3D-printed scaffolds for organs such as bladders, later coated with a patient's own cells. These pioneering efforts suggested that additive manufacturing could become a core platform for bioprinting and regenerative medicine.

By the mid-2000s, customized dental appliances, hearing aids, and surgical planning models were increasingly manufactured with 3D printing. These applications demonstrated the power of patient-specific geometries and accelerated treatment planning.

In 2005, the RepRap Project was launched with the ambitious goal of building self-replicating 3D printers that could fabricate many of their own components. This open-source initiative dramatically reduced the cost of entry for 3D printing.

RepRap's designs inspired many low-cost desktop FDM printers and helped fuel the maker movement, bringing 3D printing into homes, classrooms, and small studios worldwide.

The 2010s marked a clear transition from “cool prototypes” to functional, end-use parts in sectors such as automotive, aerospace, healthcare, and consumer products.

In the early 2010s, research teams and companies produced unmanned aircraft and vehicle bodies that relied heavily on 3D-printed components. These projects showed that additive manufacturing was capable of structural parts, not just visual models.

Such milestones demonstrated that complex, lightweight geometries could be optimized for performance and manufactured without traditional tooling.

By the mid-2010s, multi-material and full-color printers enabled parts with varying stiffness, transparency, and surface textures in a single build. This made it possible to create prototypes that closely matched the appearance and feel of final products.

At the same time, powder-bed and resin-based processes improved surface quality, consistency, and strength, making short-run production a practical reality.

This section benefits from high-quality application photos showing 3D-printed drones, automotive components, and functional end-use products.

Recent years have seen 3D printing move firmly into the realm of intelligent, scalable production with strong focus on automation, quality, and sustainability.

Modern additive manufacturing equipment is engineered for production environments, not just prototyping labs. Machines now offer repeatable tolerances, material traceability, and integration with manufacturing execution systems.

These features make 3D printing suitable for regulated industries such as aerospace and medical, especially when combined with robust quality standards and validation procedures.

AI-driven software increasingly automates tasks like support generation, build orientation, and quality monitoring. This reduces the need for manual intervention and helps detect issues earlier in the process.

Micro 3D printing technologies achieve extremely fine feature sizes, enabling intricate medical devices, microfluidic chips, and high-density electronics applications that would be difficult or impossible with conventional machining.

The latest chapter in the 3D printing timeline pushes beyond factories into infrastructure, space missions, and resource-conscious manufacturing.

Large-scale concrete and mortar printers are used to build walls and structural elements for houses and other buildings. These systems can reduce construction time and labor while enabling new architectural designs.

Pilot projects around the world explore 3D-printed homes, schools, and emergency shelters as potential answers to housing shortages and post-disaster reconstruction.

Researchers are also experimenting with 3D-printed food, which could help optimize storage and preparation for long-duration space missions. Additive manufacturing is attractive in space because it reduces the need to carry large inventories of spare parts.

At the same time, improved material recycling and energy-efficient processes support sustainability goals by reducing waste and environmental impact across the production chain.

Year | Milestone | Why It Matters |

1980 | Early UV-based rapid prototyping concepts | Foundation for resin-based 3D printing. |

1986–1988 | Stereolithography patent and first commercial SLA printer | Launch of industrial rapid prototyping. |

Late 1980s | SLS and FDM introduced | Powder-bed fusion and extrusion expand materials and applications. |

1990s | Color and higher-resolution printing | Better aesthetics and detailed functional prototypes. |

Around 1999 | Early 3D-printed organ scaffolds | Proof-of-concept for medical and bioprinting applications. |

2005 | RepRap open-source self-replicating printer | Sparks low-cost and desktop 3D printer revolution. |

Early 2010s | 3D-printed aircraft and vehicle bodies | Demonstrates structural and lightweight potential. |

Mid-2010s | Commercial multi-material and full-color printers | Enables realistic prototypes and complex products in one build. |

2020s | AI-driven workflows and construction-scale printing | Moves 3D printing toward intelligent, large-scale production. |

A simple visual timeline or icon set placed near this table enhances readability and helps users quickly scan the history.

Modern manufacturers rely on 3D printing as a critical part of the product development lifecycle, not just a niche technology.

Typical steps include:

1. Concept validation – Designers print early concept models to assess form and ergonomics.

2. Functional prototyping – Engineering teams test mechanical performance, fit, and function.

3. Pilot production – Small batches validate assembly, packaging, and field reliability.

4. Bridge manufacturing – 3D printing fills the gap while high-volume tooling is prepared.

5. End-use production – Certain geometries and volumes justify additive as a permanent method.

By inserting 3D printing at multiple points in this pipeline, teams can reduce risk, cut lead times, and maintain flexibility in design and manufacturing decisions.

To make the history of 3D printing more actionable, it helps to connect specific milestones to process-selection decisions that teams face today.

Key factors to consider include:

- Application type: Concept model, functional prototype, tooling, or production part.

- Material requirements: Plastics, elastomers, metals, or specialized materials.

- Volume and cost: One-off items versus hundreds or thousands of units.

- Tolerance and surface finish: Cosmetic quality versus high-precision engineering needs.

Common guidelines for process selection:

- SLA: Best for high-detail, smooth-surface prototypes and intricate features.

- SLS or MJF: Ideal for durable, functional parts and short-run production, especially in nylon-based materials.

- FDM: Cost-effective for larger parts and straightforward functional testing.

- Metal additive processes: Suitable for high-performance metal parts with complex internal channels and weight-saving structures.

A decision-tree graphic or a side-by-side comparison chart inserted here can help readers quickly identify which process aligns with their project.

The most efficient manufacturing strategies often combine additive technologies with established processes such as CNC machining, injection molding, and metal stamping.

Examples of hybrid approaches include:

- Using 3D-printed fixtures, jigs, and inserts to support molding or stamping operations.

- Printing complex internal geometries and then machining critical surfaces for tight tolerances.

- Producing low-volume or customized variants with 3D printing while manufacturing core high-volume parts via molding or stamping.

This combination leverages the strengths of each method, balancing flexibility, cost, speed, and performance from prototype through full-scale production.

If your team is exploring how 3D printing milestones translate into real manufacturing advantages, now is the time to move from theory to implementation. Share your CAD files, material requirements, and expected volumes with a manufacturing partner that understands both additive and traditional processes. A professional engineering team can review your designs, recommend the most suitable 3D printing technology, and propose an optimal combination of 3D printing, CNC machining, plastic molding, and metal stamping for your project. Reach out today to discuss your next product and turn your ideas into reliable, production-ready parts.

Modern 3D printing dates back to early experiments in the 1980s, when researchers demonstrated the first layer-by-layer photopolymerization systems and laid the groundwork for stereolithography.

The patenting and commercialization of stereolithography in the mid-1980s is often seen as the major early milestone, because it produced the first widely available industrial 3D printer.

Open-source projects such as RepRap made 3D printer designs accessible and affordable, inspiring many low-cost desktop printers and accelerating adoption among makers, educators, and startups.

Yes, many manufacturers use 3D printing for end-use parts, particularly when they need complex geometries, lightweight structures, or low-volume production that would be expensive with conventional tooling.

Recent milestones include AI-assisted workflows, micro-scale 3D printing for precision components, and large-format construction printers that produce building elements and housing structures.