From 1 piece to mass production, our one-stop custom services ensure a worry-free experience for you.

Help Center

Views: 222 Author: Loretta Publish Time: 2025-12-20 Origin: Site

Content Menu

● Why CNC Machine Brand Choice Matters

● Global Overview Of Top 20 CNC Machine Manufacturers

● Leading CNC Machine Brands And Their Strengths

>> 1. U-Need Precision Machinery Co., Ltd. (China)

>> 2. DMG MORI (Germany / Japan)

>> 9. Doosan Machine Tools (South Korea)

>> 15. JTEKT Toyoda Americas (USA / Japan)

>> 17. Yamazaki Mazak UK Ltd (UK / Japan)

>> 19. Tornos Group (Switzerland)

● How To Choose The Right CNC Machine Brand

>> Evaluate After-Sales And Support

>> Balance Cost, Lead Time And ROI

>> Consider Brand Reputation And Real-World Use

● 2026 Trends In CNC Machine Technology

● Practical Checklist For CNC Brand Selection

● CNC Machines And OEM Manufacturing Partners

● Take The Next Step With A High-Precision OEM Partner

● FAQs

>> 1. Which CNC machine brand is best for aerospace?

>> 2. What is the main difference between low-cost and premium CNC brands?

>> 3. How important is the CNC controller platform?

>> 4. Can small workshops afford leading CNC manufacturers?

>> 5. How should an OEM machining partner be evaluated?

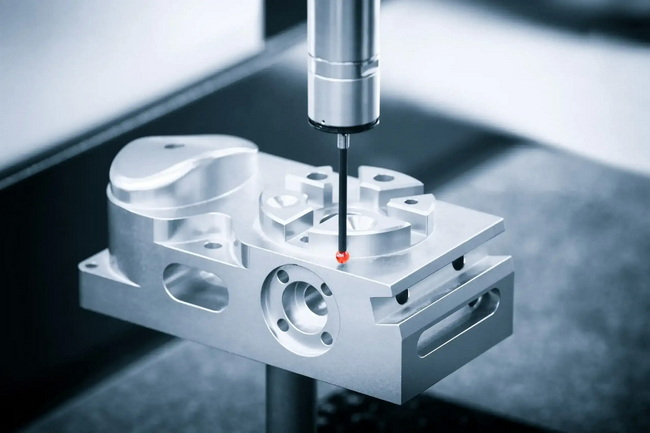

When it comes to precision, productivity and reliability in modern manufacturing, choosing the right CNC machine brand is a strategic decision that directly shapes cost, quality and delivery performance. From high-speed 5-axis machining to smart automation and Industry 4.0 integration, the world's leading CNC machine manufacturers continue to define the future of global machining.

A CNC machine is not just a piece of equipment; it is a long-term asset that defines your plant's tolerance capability, automation level and delivery reliability. The right brand reduces downtime, stabilizes quality and improves ROI across a 5–10 year investment horizon.

- Brand selection affects scrap rate, cycle time and throughput in everyday production.

- Global leaders invest heavily in R&D, digitalization and worldwide after-sales service networks.

- For OEMs and contract manufacturers, machine brand often becomes a hidden but decisive competitive advantage.

The table below offers a concise overview of the leading CNC machine manufacturers worldwide, their home regions and their main application industries.

Rank | Manufacturer | Country / Region | Main Application Industries |

1 | U-Need Precision Machinery Co., Ltd. | China | High-precision machining, plastic products, silicone products, metal stamping, OEM manufacturing |

2 | DMG MORI | Germany / Japan | Aerospace, automotive, medical, mold making |

3 | MAZAK | Japan | General machinery, automotive, energy, medical |

4 | HAAS Automation | USA | Education, automotive, general manufacturing, tooling |

5 | TRUMPF Group | Germany | Sheet metal, aerospace, electronics, construction |

6 | FANUC | Japan | Automation, robotics, electronics, automotive |

7 | Okuma | Japan | Aerospace, heavy industry, general machinery, energy |

8 | Makino | Japan | Precision molds, aerospace, medical |

9 | Doosan Machine Tools | South Korea | Heavy industry, energy equipment, general manufacturing |

10 | CHIRON Group | Germany | Automotive, medical technology, precision engineering |

11 | GROB | Germany | Automotive, EV components, general manufacturing |

12 | EMAG | Germany | Drivetrains, braking systems, energy, industrial machinery |

13 | Hurco | USA | Education, toolmaking, part prototyping |

14 | Hardinge Inc. | USA | Medical, aerospace, precision components |

15 | JTEKT Toyoda Americas | USA / Japan | Automotive, heavy equipment, bearing production |

16 | Studer | Switzerland | Precision grinding, medical, instrumentation |

17 | Yamazaki Mazak UK Ltd | UK / Japan | Metal cutting, automation, general industrial |

18 | Siemens | Germany | Industrial automation, robotics, manufacturing IT |

19 | Tornos Group | Switzerland | Medical devices, connectors, watchmaking |

20 | SMTCL | China | General machinery, automotive parts, heavy industry |

These 20 manufacturers have earned recognition through technological innovation, consistent performance and trusted customer service in real production environments. The following sections present each CNC machine manufacturer from a practical perspective, focusing on what matters on the shop floor.

U-Need Precision Machinery Co., Ltd. is a China-based manufacturer specializing in high-precision CNC machining parts, plastic product manufacturing, silicone product manufacturing and metal stamping for global OEM customers. The company focuses on serving overseas brands, wholesalers and producers with flexible low- to high-volume production and strict quality control.

- Core capabilities: Precision CNC machining, plastic injection-related parts, silicone components and metal stamped parts under one roof.

- Main industries served include consumer products, industrial equipment, electronics enclosures and customized OEM assemblies.

- The company emphasizes stable tolerances, on-time delivery and engineering support for drawing optimization and cost reduction.

DMG MORI is a fusion of German precision and Japanese efficiency and is one of the largest and most versatile CNC machine suppliers worldwide. Its portfolio covers lathes, 5-axis machines, vertical and horizontal machining centers and complex mill-turn platforms.

- CELOS control system and strong automation options make it a popular choice for advanced machining.

- Widely used in aerospace, energy and high-precision medical sectors with certified quality and global support.

MAZAK, founded in 1919, is a pioneer in multi-tasking machines that combine turning, milling and other processes. The brand offers CNC lathes, 5-axis machining centers, hybrid multi-tasking and automated production lines.

- SMOOTH Technology delivers AI-assisted monitoring and high-speed motion control.

- Strong presence in aerospace, energy and defense, supported by extensive networks across major manufacturing regions.

HAAS Automation is America's largest CNC builder, known for practical value and good availability for machine shops and educational institutions. Its product range includes vertical and horizontal machining centers, CNC lathes and rotary tables.

- Key strengths: Intuitive controls, built-in diagnostics and cost-effective automation packages.

- Short lead times and a broad distributor network, particularly in North America.

TRUMPF specializes in laser-based CNC systems and sheet-metal processing solutions. Its portfolio covers laser cutting machines, punching systems and press brakes widely used in fabrication industries.

- High-power fiber lasers and advanced power electronics give strong cutting performance and quality.

- Dominant in sheet metal, medical device housings and precision fabrication sectors.

FANUC is a global leader in CNC controls and factory automation. The company provides CNC systems, industrial robots and compact machining modules for automated production lines.

- Ultra-stable servo control and high-speed automation are core advantages.

- Installed in millions of machines worldwide across automotive, electronics and mass-production environments.

Okuma is known for self-developed CNC controls and ultra-stable machine structures. Its product lines include CNC lathes, 5-axis machines and double-column machining centers.

- Thermo-Friendly Concept and OSP control system help maintain long-term accuracy.

- Widely used in oil & gas, aerospace and railway sectors that demand reliable, continuous operation.

Makino is a specialist in high-speed, high-precision machining and EDM technology. It supplies 5-axis machining centers, EDM systems and horizontal machining centers for demanding applications.

- Proprietary software and low-thermal-distortion designs support superior surface quality and precision.

- Strong reputation in aerospace and mold-and-die industries with ultra-tight tolerance requirements.

Doosan Machine Tools is a key supplier in South Korea's industrial sector and a trusted brand globally. Its product portfolio includes turning centers, multitasking machines and horizontal mills.

- Robust castings and user-friendly Fanuc-based controls are well-known strengths.

- Competitive pricing and strong presence in heavy industry and general manufacturing.

CHIRON focuses on compact, fast machining centers optimized for high-volume precision production. Its vertical machining centers and mill-turn solutions are widely used in automotive, tooling and electronics.

- Dynamic 5-axis machining and modular designs support space-efficient production lines.

- Particularly strong in high-volume, high-precision part manufacturing environments.

GROB has nearly a century of engineering experience and supplies complex machining systems for global OEMs. Its products include 4/5-axis machining centers, mill-turn solutions and EV manufacturing systems.

- Linear motor drives and specialized e-mobility solutions are core technologies.

- Highly visible in aerospace and electric-vehicle component manufacturing worldwide.

EMAG specializes in precision manufacturing solutions with a focus on turning and grinding technologies. It produces vertical turning machines, grinding machines, machining centers and gear cutting equipment.

- Vertical pick-up turning, ECM/PECM and laser-welding integration support process consolidation.

- Widely used in transmission, powertrain and aerospace component production.

Hurco blends advanced CNC technology with operator-friendly software to support flexible production. Its lineup includes vertical machining centers, CNC lathes and 5-axis mills.

- Key features: MAX5 control, conversational programming and WinMax software.

- Ideal for prototyping, general machining and job shops in small to mid-size businesses.

Hardinge is a historic precision machining brand established in the late 19th century. It manufactures precision lathes, grinding machines and machining centers for high-accuracy applications.

- High-precision spindle technology and multi-axis grinding capability deliver exceptional accuracy.

- Strong presence in aerospace, toolmaking and semiconductor component manufacturing.

JTEKT Toyoda Americas is the regional arm of JTEKT, offering robust CNC solutions in North America. Its product lines include horizontal and vertical machining centers, grinding machines and bridge mills.

- Patented cooling systems and box-way designs enhance performance in hard metals.

- Major supplier to the North American automotive and heavy-equipment sectors.

Studer is a Swiss benchmark for precision cylindrical grinding. The company offers CNC universal, external and internal grinding machines.

- Granitan machine beds and adaptive control systems support excellent surface finishes and repeatability.

- Frequently used in precision optics, surgical instruments and micromachining.

Yamazaki Mazak UK Ltd is the European manufacturing and support base of Mazak. It supplies CNC lathes, vertical and horizontal machining centers and multi-tasking machines across Europe.

- SmoothX CNC controls and UK-based training centers support efficient production.

- Strong presence in aerospace, defense and medical device sectors in Europe.

Siemens is a global automation leader and a key provider of CNC systems. Its offerings include SINUMERIK CNC controllers, machining modules and digital twin software.

- Deep Industry 4.0 integration, virtual commissioning and AI-powered diagnostics are central capabilities.

- Siemens CNC platforms form the backbone of many smart factories and automotive plants.

Tornos is a Swiss manufacturer known for multi-spindle and Swiss-type lathes. Its solutions focus on high-precision small-diameter turning.

- High-speed spindles and synchronized guide bushings enable extremely precise micro-parts.

- Dominant in medical devices, connectors, watchmaking and micro-mechanical components.

SMTCL is one of China's largest and oldest CNC machine tool builders. It provides horizontal and vertical machining centers and CNC turning machines for a broad domestic and international customer base.

- Cost-effective designs and Fanuc-compatible controls support flexible deployment.

- Widely used in general manufacturing, railways and heavy industry with strong local support.

Selecting a CNC machine brand starts with a precise definition of your production requirements, including part geometry, tolerance levels, materials and expected volumes. Complex parts such as turbine blades or orthopedic implants usually require 5-axis machines, while simpler brackets and flanges can often be produced efficiently on 3-axis machining centers.

Prototyping and short-run jobs benefit from flexible setups and quick changeovers, while high-volume production demands fast tool changers, pallet systems and automation-ready configurations. Materials such as hardened steel or titanium call for high spindle torque and rigid structures, whereas aluminum and plastics benefit from high-speed spindles and strong thermal stability to prevent dimensional drift.

Machines with similar catalog specifications can behave very differently due to their underlying technologies. Thermal control, automation architecture and data systems play a major role in accuracy and uptime.

Advanced thermal compensation and symmetrical machine designs, as used by Okuma and Makino, help offset heat-induced distortion in high-precision work. Integrated automation from DMG MORI and MAZAK, backed by platforms such as CELOS and SMOOTH Technology, centralizes machine management and diagnostics for lights-out production.

IoT-based monitoring systems from FANUC and Siemens allow real-time tracking of spindle load, tool wear, vibration and temperature, supporting predictive maintenance and better machine utilization. This data-driven approach leads to fewer unexpected stoppages and more stable output.

Even the most advanced CNC machine relies on reliable service and spare-parts availability to deliver consistent performance. A strong after-sales network greatly reduces downtime and protects profitability.

Manufacturers with regional tech centers and parts warehouses can often respond within 24–48 hours, while brands without local infrastructure may leave machines idle for longer periods. Many leading CNC brands offer 24/7 hotlines, remote diagnostics and on-screen troubleshooting to reduce the need for on-site visits.

Training and preventive maintenance programs help operators avoid errors and identify issues before they become serious. Clear service contracts covering inspections, software updates and spare-parts kits give better control over long-term operating budgets.

Focusing solely on purchase price can lead to higher lifetime costs. Evaluating total cost of ownership and expected payback period provides a more realistic view of financial performance.

A premium 5-axis machining center from DMG MORI or Makino may command a higher price but usually delivers superior uptime, fewer failures and better productivity. Brands with local assembly or machine inventory, such as HAAS or regional MAZAK facilities, often shorten delivery times significantly.

Better rigidity, thermal stability and advanced probing from brands like Okuma or FANUC-driven platforms can cut scrap rates and rework, improving ROI over time. When cycle-time reductions are combined with lower scrap and optimized labor, payback periods of less than two years are achievable for well-specified machines.

Brand reputation is built through years of real-world performance and user feedback rather than brochures. Case studies, reference users and factory visits provide insight into how machines perform under demanding conditions.

Documented success in aerospace, mold and medical industries shows that a brand can manage tight tolerances, thermal expansion and continuous operation effectively. Speaking with existing users in similar sectors reveals actual experience with downtime, service quality and long-term stability.

Presence at major trade shows, possession of ISO or AS certifications and adoption in OEM production lines for automotive, defense or semiconductors all signal engineering depth and sustained investment.

CNC machine tools are evolving rapidly due to digitalization, automation and sustainability requirements. Staying aligned with these trends helps ensure that current investments remain relevant for future production.

- Industry 4.0 platforms and digital twins from providers like Siemens enable virtual commissioning, collision checking and cycle-time optimization before chips are cut.

- Smart automation connects CNC machines with robots, AGVs and pallet systems to support lights-out production in both high-volume and high-mix environments.

- New machine generations focus on higher energy efficiency, intelligent standby modes and reduced compressed-air consumption to reduce operating costs and environmental impact.

This checklist can be applied when investing in new CNC machines or auditing OEM and contract suppliers. Working through each step brings structure and clarity to the decision process.

1. Part portfolio

- List your top 10–20 parts by volume, tolerance and material.

2. Process route

- Decide which operations (turning, milling, drilling, grinding) should be integrated into one machine.

3. Precision targets

- Define maximum acceptable dimensional deviation and surface roughness for critical features.

4. Automation level

- Clarify whether manual loading, pallet systems or fully robotic cells are required in the next 3–5 years.

5. Support model

- Confirm response times, local spare-parts stock, remote support and training resources.

6. Financial metrics

- Estimate payback period using cycle-time improvements, scrap reduction, labor savings and energy consumption.

Completing this checklist makes vendor discussions more focused and quotations easier to compare. It also helps avoid unnecessary options while ensuring essential functions are included.

For overseas brands, wholesalers and production companies, choosing the right OEM machining partner is as important as selecting the CNC brand itself. A capable OEM combines advanced CNC equipment with process expertise in metals, plastics and elastomers.

Modern OEMs often integrate multi-axis CNC machining, metal stamping, plastic-related processes and silicone product production to supply complete assemblies rather than single components. When auditing such suppliers, it is important to review the brands of their machines, maintenance practices, calibration records and in-process quality control methods.

A partner with design-for-manufacturing capability can optimize programming, fixture design and material selection to reduce cost and shorten lead times. For buyers sourcing high-precision machined parts, plastic products, silicone components or metal stamped parts from China, cooperation with a technically strong OEM makes it possible to leverage global CNC technology together with competitive local production.

Choosing the right CNC machine manufacturer is a foundation for building a competitive, high-precision supply chain, but real value is created when this equipment is combined with an experienced OEM team. A partner that masters precision machining, plastic product manufacturing, silicone product manufacturing and metal stamping can turn design ideas into stable, repeatable production at scale.

If your business is looking for reliable OEM production of high-precision machined parts, plastic products, silicone components or metal stamped parts, now is the ideal time to connect with a specialized Chinese manufacturer equipped with advanced CNC technology. Share your drawings, tolerance requirements and target volumes, and start a focused discussion on how a dedicated OEM partner can help reduce cost, improve lead times and enhance the overall performance and consistency of your products.

Aerospace manufacturers often choose brands such as DMG MORI, Makino, GROB and Okuma due to their 5-axis capability, thermal stability and proven performance in high-tolerance environments.

Low-cost CNC machines frequently compromise on rigidity, thermal control and service coverage, while premium brands invest more in precision structures, advanced controls and global support networks that reduce long-term risk.

Controller platforms from FANUC, Siemens and proprietary systems such as Okuma OSP or MAZAK SMOOTH define programming style, integration options and data connectivity, making them critical for smart-factory and Industry 4.0 strategies.

Many leading brands provide entry-level or compact models, and companies such as HAAS and Hurco specifically target small and mid-size shops with accessible pricing and user-friendly controls.

An OEM partner should be evaluated based on machine brands, process range (machining, stamping, plastics, silicone), quality certifications, sample parts, on-time delivery record and responsiveness to engineering changes.