From 1 piece to mass production, our one-stop custom services ensure a worry-free experience for you.

Help Center

Views: 222 Author: Loretta Publish Time: 2025-12-26 Origin: Site

Content Menu

● What Precision Mold Parts Manufacturers and Suppliers Do

● Why Italy Is a Strong Base for Precision Mold Parts

● Representative Italian Precision Mold Parts Manufacturers and Suppliers

>> HTM Stampi

>> CubeGroup

● Types of Precision Mold Parts in Italian Supply

● Role of Quality and Metrology

● U-NEED: A Chinese OEM Partner Supporting Precision Mold Projects

>> U-NEED's Technical Capabilities

>> OEM Service Model at U-NEED

● Italy–China Hybrid Supply Chain Strategy

>> Typical Cooperation Pattern

>> Benefits for Overseas OEM Buyers

● How to Choose Italian Precision Mold Parts Manufacturers and Suppliers

● When to Involve U-NEED in the Project

● FAQs

>> 1. What industries do Italian Precision Mold Parts Manufacturers and Suppliers typically serve?

>> 3. How do Italian companies ensure the precision and quality of mold parts?

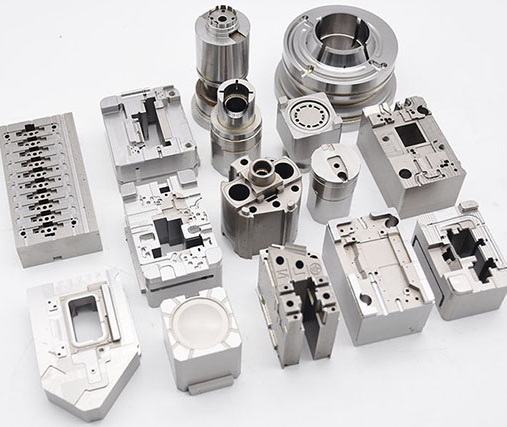

Italy is home to many advanced Precision Mold Parts Manufacturers and Suppliers that support demanding sectors such as automotive, medical, electronics, and high-end consumer products. These Italian specialists are trusted worldwide for complex mold tooling, long-life components, and stable, high-volume production performance. For overseas OEM buyers, combining Italian mold expertise with flexible Chinese OEM partners like U-NEED creates a powerful, efficient global supply chain from mold design to finished parts.[1][2][3][4][5][6]

Precision Mold Parts manufacturers and suppliers in Italy focus on ultra-accurate tooling and component production that guarantees repeatability, tight tolerances, and long service life in plastic, silicone, and metal applications. These companies are deeply involved in injection molds, multi-cavity systems, hot-runner tools, die sets, and critical inserts for sectors that require zero-defect performance.[2][3][7][1]

Typical core competencies include:

- Detailed mold engineering using 3D CAD, CAM, and simulation tools to optimize parting lines, gating, and cooling.[3][1][2]

- High-precision machining using CNC milling, EDM, grinding, and polishing to achieve tight tolerances and mirror finishes.[1][3]

- Comprehensive support services such as design for manufacturability (DFM), prototype trials, and maintenance of precision mold parts.[2][3][1]

In this context, Precision Mold Parts Manufacturers and Suppliers act not only as component suppliers but as technical partners, helping OEMs reduce scrap, improve cycle time, and stabilize large-scale production.[7][1][2]

Italian industry has a long tradition in mechanical engineering, plastics processing, and tooling, which forms a solid foundation for modern Precision Mold Parts Manufacturers and Suppliers. Many companies operate in industrial clusters that specialize in automotive, packaging, household goods, and technical plastics, allowing them to share experience and adopt cutting-edge practices quickly.[8][7][1][2]

Key strengths of Italian manufacturers and suppliers include:

- Deep experience in complex molds, including multi-material, gas-assisted, and micro-precision tools for highly technical parts.[9][1][2]

- Continuous investment in advanced CNC machining, EDM, high-tonnage injection presses, and metrology equipment for mold qualification.[3][1][2]

- Strong emphasis on craftsmanship, surface finish, and dimensional accuracy, which makes Italian precision mold parts competitive on a global level.[7][1][2]

Because of these features, Italy is frequently chosen by European and international brands for high-value projects where the performance of Precision Mold Parts Manufacturers and Suppliers is directly linked to product quality and brand reputation.[1][2][7]

The ecosystem of Precision Mold Parts Manufacturers and Suppliers in Italy includes specialists in plastic molds, silicone tooling, and metal stamping dies. While there are many companies, several representative players highlight Italy's capabilities and typical service models.[10][2][3][7][1]

HTM Stampi provides high-precision molds for demanding industries such as automotive, aerospace, and medical, offering complete design and manufacturing services along with mold maintenance and support. The company integrates advanced engineering software, modern machinery, and rigorous quality control to ensure that precision mold parts meet strict performance and durability requirements.[1]

M.P.I. Italy srl focuses on mold making for plastic injection, silicone molding, and related tooling for metal forming, covering both prototype and mass-production tools. Its services typically span from early design support through to mold trials, sampling, and ongoing optimization of mold components.[3]

CubeGroup develops and manufactures sophisticated plastic injection molds, including two-component and gas-assisted molds that serve high-tech sectors such as automotive and technical appliances. Their engineering-driven approach makes them a suitable choice for OEMs needing Italian Precision Mold Parts Manufacturers and Suppliers that can handle complex geometries and special processes.[2]

Italian plastics and molding companies described in industry overviews often integrate mold design, construction, and precision molding for global customers, especially in automotive and medical markets. Metal stamping and tooling companies in Italy also offer precision dies and progressive tools that complement plastic and silicone mold solutions in complete assemblies.[11][8][10][7]

Across these companies, precise mold parts manufacturing, technical consulting, and long-term support services form the common value proposition for international buyers.[7][2][3][1]

Precision Mold Parts Manufacturers and Suppliers in Italy are involved in a wide spectrum of mold-related components and systems. These parts are essential for stable, repeatable production, especially when OEMs require tight dimensional control and high output.[2][3][7][1]

Typical product categories include:

- Cores, cavities, and inserts for injection molds, including hardened steel or high-performance alloy components.[3][1][2]

- Ejector pins, sleeves, lifters, sliders, and guiding elements that ensure stable operation of molds under high cycles.[1][3]

- Hot-runner and cold-runner components, manifolds, and nozzles tailored to specific resins and part geometries.[2][1]

- Precision dies and punches for metal stamping, progressive dies, and combination tools that support high-speed presses.[10][3]

Because these parts are manufactured by Precision Mold Parts Manufacturers and Suppliers with advanced equipment and metrology, they can sustain long production runs with minimal wear and dimensional drift.[3][1][2]

For Precision Mold Parts Manufacturers and Suppliers, accuracy and consistency are critical, especially when parts run in high-cavitation molds or multi-impression stamping dies. Italian companies typically operate dedicated quality departments that rely on advanced measurement technology to verify every stage of production.[8][1][3]

Common quality practices include:

- Use of coordinate measuring machines (CMM), optical systems, and surface roughness testers for detailed inspection of mold parts.[8][1][3]

- Full documentation of inspection results, material certificates, and heat treatment reports to support traceability for regulated industries.[1][3]

- Process control strategies, including statistical process control and capability analyses, to maintain stable production of precision mold parts.[8][1]

When OEM buyers choose Precision Mold Parts Manufacturers and Suppliers in Italy, this quality infrastructure reduces risk across the entire lifecycle of molds and related components.[2][3][1]

U-NEED, located in Dongguan, China, is a specialist in high-precision machining, plastic products manufacturing, silicone products manufacturing, and metal stamping, with a strong focus on international OEM services. The company works with overseas brand owners, wholesalers, and manufacturers, taking customer drawings or samples and transforming them into stable mass-production solutions.[4][5][6]

U-NEED provides a broad range of technical services that complement Precision Mold Parts Manufacturers and Suppliers in Italy:

- Custom CNC machining of complex metal components, including mold inserts, precision fixtures, and mechanical parts with tight tolerances.[5]

- Plastic product manufacturing, integrating mold design concepts with efficient injection molding for custom polymer components.[4][5]

- Silicone product manufacturing for seals, gaskets, and flexible parts, meeting strict dimensional and functional requirements.[5][4]

- Metal stamping production of brackets, connectors, and structural parts that can be used together with plastic and silicone components in final assemblies.[4][5]

By offering these services under one roof, U-NEED enables customers to link Italian precision mold technology with cost-effective serial production in Asia.[6][5][4]

As an OEM-oriented company, U-NEED structures its workflow to support the entire product development cycle for international clients. This typically involves:[6][4]

- Reviewing 2D and 3D data, tolerances, and requirements supplied by clients or their Italian Precision Mold Parts Manufacturers and Suppliers.[5][4]

- Providing feedback on manufacturability, material choices, and potential cost optimizations while respecting functional requirements.[4][5]

- Running pilot production and sample approval before moving to stable mass production using CNC machining, molding, and stamping processes.[5][4]

For buyers, this OEM service model makes it easier to turn high-end Italian mold designs into competitive products manufactured at scale.[4][5]

Combining Italian Precision Mold Parts Manufacturers and Suppliers with a Chinese OEM like U-NEED is increasingly attractive for global OEM buyers. This hybrid strategy allows businesses to balance engineering quality, cost, and delivery flexibility across different regions.[5][4][1][2]

A common structure for Italy–China cooperation looks like this:

- Italian companies handle mold design, critical mold parts manufacturing, and initial mold trials, ensuring that tools meet high standards and local certification needs.[3][1][2]

- U-NEED manages the production of high precision machined parts, molded plastic components, silicone parts, and metal stamping products based on the validated molds and technical data.[4][5]

- Both sides maintain technical communication for improvements, spare parts, and engineering changes throughout the product lifecycle.[6][5][4]

This hybrid model enables OEMs to keep strategic mold technology in Europe while ensuring competitive per-part cost and flexible capacity in China.[5][1][2][4]

For brands, wholesalers, and manufacturing companies, a joint approach involving Italian Precision Mold Parts Manufacturers and Suppliers and U-NEED offers several advantages:

- Faster development cycles through parallel engineering and clear division of responsibilities between mold technology and part production.[1][2][4][5]

- Optimized total cost of ownership, combining premium molds with cost-effective serial production and integrated logistics.[4][5]

- Better risk management by having technical support available in both Europe and Asia, which helps maintain stable supply and rapid response to quality or design issues.[2][5][1][4]

In markets with intense competition and short product life cycles, such a setup can significantly enhance competitiveness.[5][4]

Selecting the right partners in Italy is essential for the success of molding and stamping projects, especially when they are connected to an OEM like U-NEED. Buyers should evaluate suppliers systematically and not rely solely on price or brand reputation.[7][3][1][2]

Key evaluation criteria include:

- Technical expertise in your application area, such as medical, automotive, packaging, or consumer electronics.[7][8][1][2]

- Portfolio of reference projects and evidence of successfully delivering complex molds and precision parts for international customers.[7][1][2]

- Quality control systems, certifications, and metrology capabilities that match your industry's regulatory expectations.[8][3][1]

- Ability to collaborate with external partners such as Chinese OEM manufacturers and manage shared data, timelines, and quality responsibilities.[1][2][4]

By focusing on these points, OEM buyers can identify Italian Precision Mold Parts Manufacturers and Suppliers that provide long-term value instead of just short-term cost savings.[3][2][1]

Integrating U-NEED into the project at an early stage helps align mold design, component tolerances, and production methods. When Italian Precision Mold Parts Manufacturers and Suppliers are already defined, including U-NEED in technical discussions can support seamless transfer from mold validation to serial production.[4][5]

Typical moments to involve U-NEED include:

- During initial DFM reviews, so that plastic, silicone, and metal part designs are compatible with both Italian tooling and Chinese production methods.[5][4]

- Before finalizing tolerances and materials to ensure that requirements are realistic for long-term production in the selected processes.[4][5]

- When planning ramp-up and logistics, enabling U-NEED to propose packaging concepts, shipment frequency, and inventory strategies.[5][4]

With this cooperation, OEM buyers can ensure that Precision Mold Parts Manufacturers and Suppliers in Italy and U-NEED in China work as a coordinated team rather than separate providers.[2][1][4][5]

Italian Precision Mold Parts Manufacturers and Suppliers provide world-class mold design, tooling, and precision components that underpin complex plastic, silicone, and metal stamping projects in many industries. By combining these Italian strengths with the high-precision machining, plastic and silicone molding, and metal stamping capabilities of a Chinese OEM partner like U-NEED, overseas brands, wholesalers, and manufacturers can create an efficient, reliable, and globally competitive supply chain.[6][7][3][1][2][4][5]

Italian Precision Mold Parts Manufacturers and Suppliers commonly serve automotive, aerospace, packaging, medical, consumer goods, and technical plastics markets where precision and reliability are critical. Many also support electronics and specialty applications that require complex molds and high-quality mold parts with extremely tight tolerances.[9][8][7][1][2]

Yes, Italian Precision Mold Parts Manufacturers and Suppliers often cooperate with international partners, while OEM factories like U-NEED handle large-scale production of machined parts, plastic components, silicone products, and metal stamping parts. This collaboration lets overseas buyers benefit from European engineering and Chinese production efficiency in the same project.[1][2][4][5]

Italian Precision Mold Parts Manufacturers and Suppliers use advanced CAD/CAM tools, 3- and 5-axis CNC machining, EDM, and high-precision grinding, combined with CMM measurement and other inspection systems. They operate structured quality management systems with documented procedures, internal audits, and continuous improvement, especially for regulated industries like automotive and medical.[8][3][2][1]

A hybrid model allows overseas OEMs to obtain high-end mold engineering and critical precision mold parts from Italian suppliers while using Chinese OEM partners such as U-NEED for competitive mass production of components. This approach balances quality, cost, and delivery flexibility and reduces risk by leveraging strengths from both regions.[2][1][4][5]

Before contacting Italian Precision Mold Parts Manufacturers and Suppliers, OEM buyers should prepare 2D and 3D drawings, tolerance requirements, materials, target annual volumes, and any special standards or certifications needed. Clear technical and commercial information enables both Italian partners and OEM factories like U-NEED to provide accurate quotations, realistic lead times, and appropriate engineering proposals.[3][1][2][4][5]

[1](https://www.htmstampi.it/en/)

[2](https://cubegroup.it/en/moulds/)

[3](https://www.moulds.biz/en/services/mold-making/)

[4](https://www.uneedprecisionmachine.com/About-u-need.html)

[5](https://www.uneedpm.com)

[6](https://www.uneedprecisionmachine.com/about-us)

[7](https://baiwemolding.com/top-injection-molding-companies-in-italy/)

[8](https://forteq-precision-plastics.com/en)

[9](https://barnesmoldingsolutions.com/en/ms-home)

[10](https://ensun.io/search/metal-stamping/italy)

[11](https://www.nolato.com/en/Stories/Manufacturing-precision-mold-tools)