From 1 piece to mass production, our one-stop custom services ensure a worry-free experience for you.

Help Center

Views: 222 Author: Loretta Publish Time: 2025-12-23 Origin: Site

Content Menu

● Overview of Precision Mold Parts Manufacturers and Suppliers in Russia

● Key Sectors Using Precision Mold Parts in Russia

● Representative Russian Injection Molding and Tooling Companies

● Why Many Russian Buyers Work with Chinese Precision Mold Parts Manufacturers and Suppliers

● About U-NEED: A Chinese OEM Partner for Russian Brands

● How U-NEED Supports Precision Mold Parts Manufacturers and Suppliers in Russia

● Core Capabilities of U-NEED for Russian OEM Customers

● Quality Control Expectations for Precision Mold Parts Manufacturers and Suppliers

● Cost and Lead-Time Considerations for Russian Buyers

● Practical Sourcing Tips for Working with Russian and Chinese Suppliers

● Sample Cooperation Workflow Between a Russian Mold Maker and U-NEED

● Benefits for Foreign Brand Owners and Wholesalers Serving Russia

● How to Evaluate if U-NEED Is the Right OEM Partner

● Local vs. Overseas Precision Mold Parts Suppliers for Russia

● FAQs

>> 2. Why do Russian firms import molds and precision parts from Chinese OEM suppliers?

>> 3. How can U-NEED cooperate with Russian Precision Mold Parts Manufacturers and Suppliers?

>> 5. Is it better to work only with Russian suppliers, or combine them with overseas OEM partners?

Russia has a growing ecosystem of Precision Mold Parts Manufacturers and Suppliers serving automotive, consumer goods, electronics, and industrial sectors, while many Russian buyers still rely heavily on high-precision OEM partners in China for complex tooling and components. For foreign brand owners, wholesalers, and manufacturers, combining Russian local support with reliable Chinese OEM factories such as U-NEED often delivers a strong balance of cost, quality, and lead time.[1][2]

Russia's Precision Mold Parts Manufacturers and Suppliers cluster around major industrial regions such as Moscow, Saint Petersburg, and other automotive and plastics hubs that host diversified manufacturing. These companies typically focus on plastic injection molds, metal tooling, and custom molded parts for domestic OEMs and large industrial customers that demand stable quality and repeatable production.[3]

The local market is complemented by a large volume of imported injection molds and precision mold parts from Asia, underscoring the importance of cross-border OEM cooperation in the Russian supply chain. Many Russian Precision Mold Parts Manufacturers and Suppliers therefore work in hybrid models, combining in-house capabilities with trusted overseas partners to cover complex or highly specialized components.[2][1]

Russian Precision Mold Parts Manufacturers and Suppliers serve a broad range of downstream sectors that depend on stable tooling and consistent quality in mass production. Understanding these end-markets helps foreign buyers evaluate whether a given supplier's experience matches their own product requirements and performance targets.[4][3]

Major sectors include:[3]

- Automotive OEM and aftermarket components

- Household appliances and white goods

- Consumer electronics and communication devices

- Construction and building hardware

- Packaging, logistics products, and consumer goods

These sectors together create continuous demand for reliable Precision Mold Parts Manufacturers and Suppliers that can respond quickly to new designs and mold maintenance needs.[3]

While this article focuses on sourcing strategies rather than an exhaustive directory, several Russian companies illustrate the capabilities commonly found among Precision Mold Parts Manufacturers and Suppliers in the region. They show the type of services foreign and domestic buyers can expect from local suppliers.[3]

Typical examples include companies such as be:plast (a Russian manufacturer of injection-molded plastic parts for logistics, electronics, and construction), as well as tooling-oriented firms that provide mold design, fabrication, and plastic injection services under one roof. Together, these Precision Mold Parts Manufacturers and Suppliers demonstrate that Russia has a solid domestic base, even though many factories still complement their capacity with imported molds and components.[5][1]

Trade statistics show that Russia imports substantial volumes of injection molds, plastic molds, and related tooling from Asia, especially China, due to the attractive cost-performance ratio. For complex multi-cavity molds, tight-tolerance mold components, or quick repeat orders, Russian buyers frequently depend on Chinese Precision Mold Parts Manufacturers and Suppliers that specialize in export-oriented OEM projects.[6][1]

Typical advantages of Chinese OEM partners include:[2]

- Large installed base of CNC machining, EDM, grinding, and metrology equipment

- Extensive experience serving global automotive, medical, and electronics brands

- Competitive pricing for high-volume and recurring orders

- Ability to supply complete assemblies combining metal, plastic, and silicone parts

As a result, Russian Precision Mold Parts Manufacturers and Suppliers often position themselves as local integrators that work closely with Chinese factories to deliver finished solutions to end users.[1]

U-NEED is a China-based OEM supplier specializing in high-precision mechanical machining parts, plastic product manufacturing, silicone product manufacturing, and metal stamping for overseas brand owners, wholesalers, and manufacturers. This OEM-only positioning allows partners to retain full branding and market control in Russia and other destinations.

By integrating precision machining, plastic molding, silicone molding, and stamping, U-NEED enables Russian Precision Mold Parts Manufacturers and Suppliers to consolidate multiple processes within a single OEM partner. This integrated model helps reduce coordination cost, improve delivery consistency, and simplify quality management for Russian and international customers alike.[7][2]

Russian Precision Mold Parts Manufacturers and Suppliers increasingly cooperate with Chinese OEM factories to expand their technical range and stabilize capacity without heavy capital investment. U-NEED can act as a behind-the-scenes manufacturing extension for Russian mold makers, injection molders, and stamping companies that need secure, repeatable production.[6]

Common cooperation models include:[2]

- Contract manufacturing of precision mold components such as core pins, inserts, cavities, ejector sleeves, and customized mechanical parts

- Batch production of plastic, silicone, and metal stamped parts based on Russian drawings and 3D files

- Joint development where the Russian partner manages design and customer communication, while U-NEED focuses on precision production and process optimization

This partnership approach allows Russian Precision Mold Parts Manufacturers and Suppliers to offer broader solutions to end users while maintaining their local customer relationships.[8]

To serve Russian Precision Mold Parts Manufacturers and Suppliers effectively, U-NEED invests in modern machining and molding equipment along with standardized quality procedures that support export projects. This infrastructure makes it possible to maintain consistent performance from initial samples through mass production runs.[7]

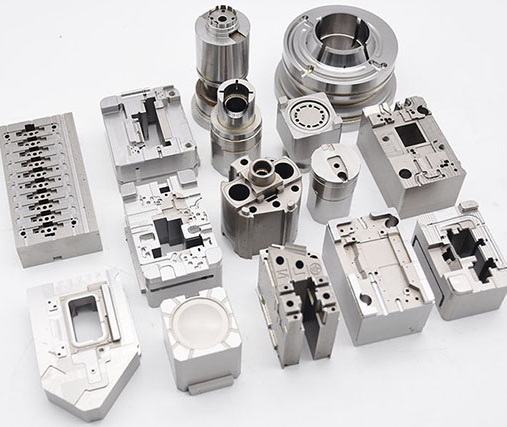

Key capabilities relevant to Russian buyers include:[2]

- CNC turning and milling centers for high-precision mechanical parts and mold components

- Surface grinding, wire-cut EDM, and die-sinking EDM for mold bases, inserts, and complex cavities

- Plastic injection molding for engineering resins and commodity plastics in a wide range of shot sizes

- Silicone product manufacturing for seals, gaskets, soft-touch components, and medical-grade parts where needed

- Progressive and single-shot metal stamping for brackets, terminals, shields, and structural components

By combining these processes under one OEM framework, U-NEED supports projects where Russian Precision Mold Parts Manufacturers and Suppliers require flexible, multi-process manufacturing.[9]

Global buyers evaluating Precision Mold Parts Manufacturers and Suppliers—whether in Russia or China—expect traceable quality systems and clearly defined process control. For Russian brands importing molds or complex assemblies, robust quality management is essential to ensure compatibility with local production lines.[10]

Typical quality-control elements include:[6]

- Incoming inspection of raw materials, including certificates and traceability documentation

- In-process inspection using micrometers, gauges, CMMs, projectors, and hardness testers

- Final inspection reports and dimensional records attached to each batch or shipment

- Documented non-conformance management and corrective action procedures

When U-NEED works with Russian Precision Mold Parts Manufacturers and Suppliers, these quality steps help integrate overseas production into local quality systems smoothly.[2]

Precision Mold Parts Manufacturers and Suppliers in Russia can react quickly to urgent maintenance, tool repairs, and smaller production batches that require on-site support. However, new molds and larger volumes of complex precision parts often become more economical when sourced from specialized OEM factories abroad.[3]

When comparing Russian and Chinese options, buyers usually evaluate:[6]

- Total landed cost, including tooling, unit price, freight, and potential customs duties

- Lead time for mold design, fabrication, testing, and iterative modifications

- Supplier flexibility in handling engineering changes, emergency orders, and long-term programs

- Risk factors and any constraints related to cross-border trade

Many Russian firms ultimately adopt a mixed strategy: they use local Precision Mold Parts Manufacturers and Suppliers for urgent or service-oriented work, while relying on trusted Chinese OEM partners like U-NEED for core tooling and recurring precision components.[1]

When selecting Precision Mold Parts Manufacturers and Suppliers, foreign buyers benefit from a structured qualification and sourcing process that minimizes risk. This framework applies equally to Russian suppliers and to remote OEM partners.[4]

Practical steps include:[6]

- Prepare clear 2D drawings, 3D models, material specifications, and tolerance requirements before requesting quotes

- Evaluate supplier certifications, equipment lists, sample reports, and references from similar industries

- Start with a pilot order or trial mold to validate quality, communication, and schedule adherence

- Use framework agreements to define IP protection, tooling ownership, delivery terms, and after-sales responsibilities

By following these steps, buyers can identify which Precision Mold Parts Manufacturers and Suppliers are capable of supporting long-term cooperation in the Russian market.[12]

To illustrate the practical side of working with an overseas OEM, the following typical workflow shows how Russian Precision Mold Parts Manufacturers and Suppliers can collaborate with U-NEED. This model leverages both local and international strengths.

Common stages include:[2]

1. The Russian partner shares 3D models, detailed 2D drawings, materials, and target tolerances for the required parts or molds.

2. U-NEED performs manufacturability analysis, proposes process routes, and submits a quotation including tooling cost, unit price, and estimated lead time.

3. After order confirmation, U-NEED produces samples or trial shots and provides inspection reports, photos, and, if needed, videos for remote approval.

4. Once samples are approved, batch production starts under defined quality checkpoints and packaging standards.

5. The Russian partner receives the goods, performs any final operations or assemblies, and supplies the end customer under its own brand.

With this approach, Russian Precision Mold Parts Manufacturers and Suppliers can expand product ranges without heavy machine investments and still maintain control over customer relationships.[8]

Foreign brand owners and wholesalers who sell into Russia often require customized components that combine metal, plastic, and silicone. Working with an OEM such as U-NEED allows these companies to avoid building their own factories while still accessing advanced production capabilities.[2]

Key benefits include:[11]

- Access to multi-process manufacturing under a single project management team

- Ability to tailor products to Russian technical standards and end-user preferences

- Reduced overhead and project risk compared with establishing a local plant

- Faster scaling of volumes as demand grows in Russia and neighboring markets

In many cases, pairing local Russian Precision Mold Parts Manufacturers and Suppliers with an overseas OEM partner delivers maximum flexibility and resilience for foreign brands.[1]

Before choosing any OEM partner, buyers should assess both technical capabilities and strategic fit with their long-term goals. U-NEED is generally best suited to companies that require repeatable production of precision mechanical parts, plastic parts, silicone components, and metal stamping parts under private-label arrangements.[2]

Important questions to consider include:[9]

- Does your product rely heavily on precision machined or molded components that need tight tolerance control?

- Are you looking for a long-term OEM partner rather than occasional spot purchasing?

- Do you value engineering support and design-for-manufacturing input, or do you only need build-to-print service?

- Is your main market Russia and neighboring regions, requiring flexible logistics and stable replenishment?

If the answer is yes to most of these points, U-NEED can be a strong OEM complement to local Precision Mold Parts Manufacturers and Suppliers in Russia.[2]

When planning a sourcing strategy, many buyers compare domestic and overseas Precision Mold Parts Manufacturers and Suppliers to build a balanced supplier portfolio. Each side offers distinct advantages that can be combined effectively.[3]

In general, Russian suppliers provide rapid local support and straightforward communication for small batches and maintenance work, while overseas OEMs like U-NEED offer strong cost-performance for complex tooling and large-volume precision parts. A dual-sourcing model allows companies to reduce risk while optimizing price and lead time across different project types.[1][6]

Russia's ecosystem of Precision Mold Parts Manufacturers and Suppliers continues to develop, yet many local companies still depend on imported molds and precision components to meet demanding technical and cost targets. By partnering with a Chinese OEM like U-NEED that specializes in high-precision machining, plastic product manufacturing, silicone product manufacturing, and metal stamping, Russian firms and foreign brand owners can create a more resilient and cost-effective supply chain.[3][2]

A mixed sourcing strategy—combining responsive Russian suppliers for local service with experienced overseas Precision Mold Parts Manufacturers and Suppliers for complex tooling and volume parts—offers the flexibility that modern markets demand. For companies planning long-term growth in Russia and neighboring regions, building a strategic OEM relationship with U-NEED is a practical way to enhance competitiveness in precision manufacturing while maintaining control over brand and market position.[1][6]

Russian Precision Mold Parts Manufacturers and Suppliers are mainly plastic injection molders, mold makers, and metalworking firms that design and build molds, tooling, and custom parts for industrial customers. Many also act as OEM processors, supplying plastic parts, metal inserts, and assemblies for automotive, electronics, construction, and consumer goods sectors.[5][3]

Russia imports a significant volume of injection molds and precision plastic molds from China because of attractive pricing and strong production capacity. Chinese Precision Mold Parts Manufacturers and Suppliers offer large-scale machining and molding capabilities, short lead times, and experience with international quality standards, making them valuable partners for Russian buyers.[1][6]

U-NEED can serve as a contract OEM, producing precision mechanical parts, plastic parts, silicone parts, and metal stamping parts according to Russian partners' drawings and specifications. Russian Precision Mold Parts Manufacturers and Suppliers then focus on design, local customer support, and final assembly while using U-NEED as an extended production base for stable long-term supply.[8][2]

Foreign brand owners should review technical capabilities, equipment lists, quality certifications, and references from relevant industries when assessing Precision Mold Parts Manufacturers and Suppliers. They should also verify OEM export experience, IP protection policies, responsiveness, and the ability to support both Russian regulations and long-term product evolution.[12][4]

Working solely with local suppliers offers fast on-site support and simple communication but may limit cost optimization and capacity for complex or large projects. A combined approach—using Russian Precision Mold Parts Manufacturers and Suppliers for local service and overseas OEM partners like U-NEED for complex tooling and volume precision parts—often delivers the best mix of cost, quality, and flexibility.[3][6]

[1](https://www.volza.com/p/plastic-mold/import/import-in-russia/)

[2](https://www.made-in-china.com/manufacturers/russia-plastic-molds-companies.html)

[3](https://zetarmold.com/russia-injection-molding-companies/)

[4](https://www.sc-rapidmanufacturing.com/top-moulding-production-manufacturers-and-suppliers-in-russia.html)

[5](https://beplast.ru/en/about/)

[6](https://www.plasticmoulds.net/ultimate-list-of-10-precision-mold-manufacturers-in-china-for-2025.html)

[7](https://www.hongsinn.com/supplier-4326160-precision-mold-parts)

[8](https://www.facebook.com/groups/526747131797881/posts/1482032589602659/)

[9](https://www.ptms-mold.com)

[10](https://baiwemolding.com/plastic-injection-molding/)

[11](https://www.ptsmake.com/peek-injection-molding/)

[12](https://xinda-mold.manufacturer.globalsources.com/company-profile_6003002387191.htm)

[13](https://www.hollyplasticparts.com/russia-mold-making-companies/)