From 1 piece to mass production, our one-stop custom services ensure a worry-free experience for you.

Help Center

Views: 222 Author: Loretta Publish Time: 2025-12-24 Origin: Site

Content Menu

● Spain's Position in the Global Mold Industry

● What Precision Mold Parts Manufacturers and Suppliers Offer

● Industrial Strengths of Spanish Mold Makers

● Advantages of Working With Precision Mold Parts Manufacturers and Suppliers

● U-NEED: A Flexible OEM Partner From China

● Precision Machining Capabilities Supporting Mold Parts

● Plastic and Silicone Production for Global OEM Projects

● Metal Stamping and Complementary Processes

● How Spanish Companies and U-NEED Can Work Together

● Key Criteria for Selecting Precision Mold Parts Manufacturers and Suppliers

● Best Practices for Working With Overseas OEM Partners

● Building Long-Term Relationships With Precision Mold Parts Manufacturers and Suppliers

● FAQs

>> 1. How do I verify the capabilities of Precision Mold Parts Manufacturers and Suppliers?

>> 3. Can one OEM partner handle machining, molding, silicone, and metal stamping together?

>> 5. Why is a hybrid sourcing model with Spanish suppliers and a Chinese OEM like U-NEED attractive?

Spain is one of Europe's emerging centers for high-precision tooling, molds, and engineered plastic components, supported by a mix of long-established workshops and modern industrial groups that cater to demanding global markets. Foreign brands, wholesalers, and producers looking for reliable Precision Mold Parts Manufacturers and Suppliers can benefit from Spain's strong engineering base while also partnering with advanced Chinese OEM factories such as U-NEED for cost-effective and flexible production.

Spain's mold and die industry has grown around automotive, packaging, and consumer goods clusters, which has pushed local companies to reach high levels of accuracy and process control. Many Spanish Precision Mold Parts Manufacturers and Suppliers now operate as full-service partners, from concept through serial production, for customers across Europe and beyond.

The country's membership in the European Union also ensures harmonized regulations, product safety standards, and traceability, which is especially important for customers in medical devices, automotive, and industrial equipment. For overseas buyers, working with Spanish partners often feels familiar thanks to strong project management, clear documentation, and a service culture that aligns with wider European norms.

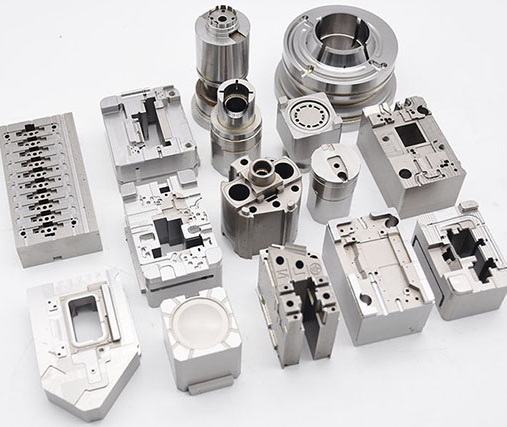

Precision Mold Parts Manufacturers and Suppliers in Spain and abroad provide a broad spectrum of services and components that support the entire lifecycle of plastic, silicone, and metal products. At their core, these companies transform design ideas and 3D models into robust tools and high-precision parts that can withstand millions of production cycles.

Typical offerings from Precision Mold Parts Manufacturers and Suppliers include:

- Custom injection molds for thermoplastic and thermoset parts, including multi-cavity tools and hot runner systems

- High-precision mold inserts, cores, cavities, sliders, lifters, ejector systems, and standard components

- Repair, modification, and optimization of existing molds to extend tool life and improve cycle time

- Precision machining services for metal components that complement mold production, such as housings, fixtures, and jigs

- Support with material selection, part design for manufacturability (DFM), and mold-flow analysis

By providing these services under one umbrella, Precision Mold Parts Manufacturers and Suppliers help reduce time-to-market and minimize the risk of defects or late-stage design changes.

Spanish mold makers benefit from a strong industrial base built around automotive parts, white goods, electronics, and packaging, all of which demand advanced tooling and consistent quality. This industrial environment has pushed many Spanish Precision Mold Parts Manufacturers and Suppliers to invest heavily in modern machinery, CAD/CAM systems, and qualified technical staff.

Key strengths of Spanish mold makers include:

- Familiarity with complex multi-part assemblies, clips, undercuts, and delicate cosmetic surfaces

- Experience integrating molds into automated production cells with robots and quality monitoring systems

- Knowledge of European standards and OEM requirements, especially for automotive and electronics

- Ability to coordinate international projects, including tool build in one country and final tuning in another

These capabilities allow Spanish suppliers to act as strategic partners who can manage entire tooling programs, sometimes in cooperation with lower-cost manufacturing bases such as China.

Partnering with professional Precision Mold Parts Manufacturers and Suppliers delivers several tangible benefits that go beyond simply buying a mold or a machined part. Reliable suppliers provide engineering insight and process discipline that can dramatically influence product performance and total cost of ownership.

Key advantages include:

- Improved dimensional stability and reduced scrap rates due to accurate mold construction and controlled processing

- Lower maintenance and fewer unplanned production stops thanks to durable mold components and proper heat treatment

- Faster changeovers and reduced setup time through the use of standardized components where possible

- More predictable project timelines, as experienced suppliers understand how to manage complex tool builds and trials

Over the long term, working consistently with trusted Precision Mold Parts Manufacturers and Suppliers helps establish stable, scalable production platforms for new and existing products.

While Spain offers local proximity and European engineering expertise, many foreign brands seek additional flexibility and cost optimization by partnering with Chinese OEM companies. U-NEED is a China-based manufacturer that focuses on high-precision machining, plastic product manufacturing, silicone product manufacturing, and metal stamping production for global customers.

U-NEED positions itself among international Precision Mold Parts Manufacturers and Suppliers by providing:

- Custom CNC machining services for high-precision parts, including mold inserts, cores, electrodes, and functional metal components

- OEM plastic injection molding for engineering plastics and commodity polymers, supporting both small and large production runs

- Silicone product manufacturing for seals, gaskets, keypads, and other flexible components used in consumer electronics, automotive, and medical applications

- Metal stamping production for brackets, terminals, shields, and structural parts that complement plastic and silicone components

With strict tolerance control, stable processes, and an OEM mindset, U-NEED works as an extension of customers' engineering and purchasing teams, rather than just as a contract manufacturer.

For both Spanish companies and U-NEED, precision machining is the backbone of high-quality mold and tooling components. Advanced equipment and thoughtful process planning enable Precision Mold Parts Manufacturers and Suppliers to achieve tight tolerances and complex geometries.

Typical machining capabilities include:

- Multi-axis CNC milling for contour-rich mold cores, cavities, and complex metal parts

- CNC turning for round inserts, bushings, sleeves, and custom shafts used in molds and assemblies

- Wire-cut EDM and sinker EDM for sharp corners, intricate pockets, deep ribs, and micro features that are impossible with standard milling

- Surface, profile, and cylindrical grinding to meet strict flatness and roundness requirements and to attain fine surface finishes

- Polishing and texturing processes to create optical surfaces, high-gloss finishes, or functional textures inside the mold cavity

By combining these technologies, Precision Mold Parts Manufacturers and Suppliers ensure that every mold component fits precisely, seals properly, and withstands the mechanical loads and temperatures it will face in production.

In addition to producing molds and precision tooling, many Precision Mold Parts Manufacturers and Suppliers either operate their own molding facilities or work closely with specialized partners. This integrated approach is particularly strong at OEM-focused companies like U-NEED, which manufacture plastic and silicone parts alongside high-precision machined components.

Key elements of these capabilities include:

- Injection molding for a wide range of plastics, from standard materials such as ABS and PP to engineering grades like PC, PBT, PA, PEEK, and filled compounds

- Overmolding and insert molding for metal-plastic combinations, soft-touch surfaces, and integrated seals or gaskets

- Liquid silicone rubber (LSR) and compression molding for silicone components requiring high cleanliness, flexibility, and temperature resistance

- Process optimization and automation to stabilize cycle times, improve repeatability, and reduce manual handling

By combining mold building, plastic injection molding, silicone molding, and precision machining, OEM suppliers can support entire product families with minimal handoff between different vendors. This creates consistency in quality and simplifies project management for foreign brands and wholesalers.

To support complete mechanical assemblies, many buyers require not only plastic and silicone components but also metal parts, especially for automotive structures, electronic connectors, and industrial hardware. Here, OEM firms like U-NEED complement their mold and machining capabilities with metal stamping services.

Typical metal stamping capabilities that mesh well with Precision Mold Parts Manufacturers and Suppliers include:

- Progressive die stamping for high-volume production of terminals, brackets, springs, and contact elements

- Single-hit and transfer stamping for larger or more complex geometries and thicker materials

- Laser cutting or fine-blanking for prototypes and small batches, enabling fast design validation before full stamping dies are built

- Secondary operations such as tapping, riveting, spot welding, and surface treatments to deliver ready-to-assemble parts

When combined with high-precision plastic and silicone components, stamped metal parts help OEM customers build complete sub-assemblies that are consistent, repeatable, and optimized for automated assembly lines.

Instead of choosing solely between Spanish suppliers and Chinese OEM factories, many foreign buyers now adopt a hybrid sourcing strategy. In this model, Spanish Precision Mold Parts Manufacturers and Suppliers focus on engineering, local interaction, and high-value operations, while U-NEED supports cost-effective and scalable production.

A typical cooperation model might look like this:

- Early design and DFM work carried out with a Spanish engineering partner, ensuring the product aligns with European standards and local regulations

- Tool design and program management managed from Spain, with detailed 3D models, tolerances, and inspection plans shared with U-NEED

- Mold building and precision machining executed at U-NEED's facilities, where advanced equipment and experienced technicians keep costs competitive

- Final mold trials, tuning, and acceptance run either in Spain or at U-NEED, depending on logistics and customer preferences

- Serial plastic, silicone, and metal part production split between Spanish molders and U-NEED according to volume, lead-time, and logistics needs

This combination allows buyers to leverage the best characteristics of both regions: responsiveness and local knowledge from Spain, and cost-effective high-precision manufacturing from China.

When selecting Precision Mold Parts Manufacturers and Suppliers, foreign brands, wholesalers, and industrial users should look beyond headline prices to evaluate deeper technical and organizational aspects. A structured set of criteria helps narrow down the field of potential partners and minimizes project risks.

Important criteria include:

- Technical capability: Range of machines, supported tolerances, and experience with similar materials and component types

- Engineering support: Ability to provide DFM suggestions, tolerance stack-up analysis, and mold-flow or structural simulations when needed

- Quality management: Presence of certifications, documented procedures, and inspection equipment such as coordinate measuring machines and optical measurement systems

- Communication and project management: Speed of response, clarity of documentation, and transparency about lead times and potential risks

- Flexibility and capacity: Willingness to support both prototype quantities and high-volume production, and ability to increase capacity as programs grow

- Long-term stability: Financial health, history in the industry, and willingness to invest in technology and people over time

Evaluating suppliers against these criteria helps identify the Precision Mold Parts Manufacturers and Suppliers that can truly support complex, long-term OEM relationships.

Collaborating across borders requires more than technical competence; it demands disciplined project management and clear expectations on both sides. Buyers who want to get the most from Precision Mold Parts Manufacturers and Suppliers in Spain and China should pay special attention to information flow and alignment.

Some best practices include:

- Provide clean 3D models, fully dimensioned 2D drawings, and clear tolerance definitions for all critical features

- Share intended material types, expected annual volumes, and any special surface or cosmetic requirements from the start

- Define quality standards and inspection methods in advance, including sampling plans, first-article inspection reports, and traceability rules

- Establish milestone reviews for design completion, mold design approval, steel ordering, first trials, and final acceptance

- Plan logistics proactively, accounting for international shipping times, customs clearance, and buffer stock during ramp-up

When these practices are followed, overseas cooperation with Precision Mold Parts Manufacturers and Suppliers becomes smoother and more predictable, even for complex multi-component projects.

The most successful OEM projects usually arise from long-term partnerships rather than one-off transactions. Precision Mold Parts Manufacturers and Suppliers gain deep understanding of their customers' preferences, standards, and pain points over time, which leads to better design decisions and fewer surprises.

Long-term collaboration enables:

- Continuous improvement programs where both sides review defect rates, cycle times, and cost drivers to identify and implement optimizations

- Faster development cycles because suppliers are already familiar with material choices, preferred gating strategies, and cosmetic expectations

- Better risk management, as trusted suppliers are more likely to flag potential issues early and propose countermeasures before they become critical

- Strategic planning for future products, with suppliers investing in equipment or training tailored to a customer's roadmap

By treating Precision Mold Parts Manufacturers and Suppliers as partners rather than interchangeable vendors, foreign brands and wholesalers can build resilient supply chains and maintain stable product quality across multiple generations of products.

Spain has firmly established itself as a valuable base for Precision Mold Parts Manufacturers and Suppliers, offering a combination of advanced engineering, strong industrial clusters, and EU-quality standards that appeal to demanding global customers. At the same time, Chinese OEM specialists such as U-NEED bring high-precision machining, plastic and silicone molding, and metal stamping capabilities that complement Spanish expertise and enable cost-effective large-scale production.

For overseas brands, wholesalers, and producers, the optimal strategy often lies in a hybrid approach: leveraging Spanish partners for engineering, local interaction, and high-value operations, while relying on U-NEED as a flexible OEM manufacturer for precision components and finished parts. This integrated model makes it easier to manage complex projects, secure consistent quality, and remain competitive in global markets that expect both technical excellence and cost efficiency from their Precision Mold Parts Manufacturers and Suppliers.

Start by reviewing documented case studies, sample parts, and machinery lists to confirm that a supplier has experience with similar materials and complexity levels. Follow up with an on-site or remote audit that examines engineering processes, quality systems, and measurement equipment so you can confirm that stated capabilities translate into real-world performance.

Provide detailed 3D models, dimensioned 2D drawings, and information about materials, volumes, and special requirements such as texture, color, or cosmetic class. Clearly stating quality expectations, inspection methods, and target lead times at the RFQ stage helps Precision Mold Parts Manufacturers and Suppliers prepare accurate quotations and realistic project timelines.

Yes, some OEM companies, including U-NEED, are structured specifically to offer integrated services that combine precision machining, plastic injection molding, silicone molding, and metal stamping. Working with such a partner simplifies communication, reduces supplier count, and helps ensure consistent quality across different types of components sourced from the same Precision Mold Parts Manufacturers and Suppliers.

Instead of focusing on unit price alone, evaluate total cost of ownership by considering tool life, maintenance requirements, scrap rates, and the potential cost of production interruptions. It is often more economical to pay slightly more for robust molds and stable processes from experienced Precision Mold Parts Manufacturers and Suppliers than to face frequent downtime, rework, or customer complaints.

A hybrid model allows buyers to enjoy the responsiveness, geographic proximity, and regulatory familiarity of Spanish suppliers while leveraging the cost advantages and scalable capacity of Chinese OEM factories such as U-NEED. This combination can shorten development cycles, improve price competitiveness, and create a resilient supply chain that is supported by multiple complementary Precision Mold Parts Manufacturers and Suppliers.