From 1 piece to mass production, our one-stop custom services ensure a worry-free experience for you.

Help Center

Views: 222 Author: Loretta Publish Time: 2025-12-23 Origin: Site

Content Menu

● What Are Punch and Die Manufacturers?

● Why China Leads in Punch and Die Manufacturing

● 1. U-Need Precision Machinery Co., Ltd. (U-NEED)

>> Technical Strength in Precision Machining

>> Expertise in Materials and Surface Treatment

>> Quality Management and Inspection

>> Advantages for Overseas OEM Clients

● 2. Dongguan Yize Mould Co., Ltd.

● 3. Wuxi Sundi Precision Tools Co., Ltd.

● 4. Dongguan MingYi Mold Parts Co., Ltd.

● 5. Zhuzhou Good Cemented Carbide Co., Ltd.

● 6. Hengshui Dongmo Precision Metal Products Co., Ltd.

● 7. Qingdao Hiparter Metal & Plastic Products Co., Ltd.

● 8. Shandong Xiaoya Precise Machinery Co., Ltd.

● 9. Dongguan Gude Precision Mold Co., Ltd.

● 10. Suzhou Jungu Precision Mould Co., Ltd.

● How to Choose the Right Punch and Die Manufacturer in China

>> 1. Technical Capability and Equipment

>> 2. Material and Process Expertise

>> 3. Quality Control and Documentation

>> 4. Communication and Engineering Support

>> 5. Cost, Lead Time, and Long-Term Support

● When to Work With U-NEED vs. Other Manufacturers

● FAQ About Punch and Die Manufacturers in China

>> 1. What industries commonly work with Punch and Die Manufacturers in China?

>> 2. How does U-Need Precision Machinery Co., Ltd. support overseas OEM customers?

>> 3. What should buyers check before ordering from a Punch and Die Manufacturer in China?

>> 4. Can Chinese Punch and Die Manufacturers handle small orders or prototypes?

China has become a global center for high-precision metal tooling, and Punch and Die Manufacturers from China now support automotive, electronics, medical, and industrial customers worldwide. These manufacturers provide cost-effective, durable tools that help overseas brands improve productivity and shorten product development cycles.

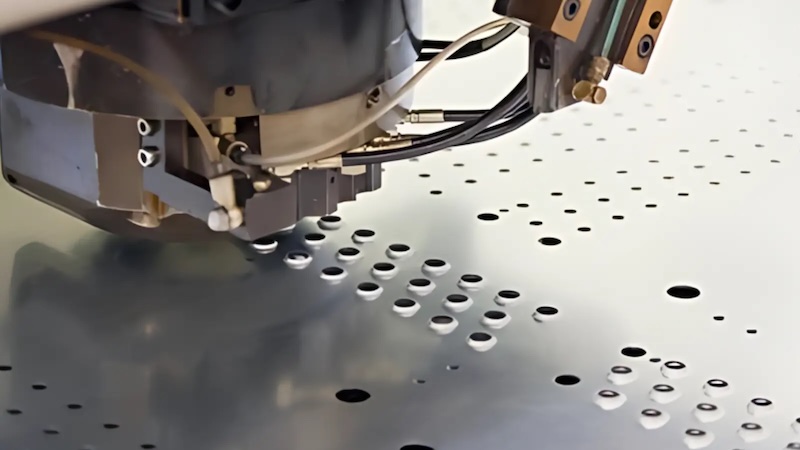

Punch and Die Manufacturers specialize in designing and producing matched tooling sets that are used in stamping, piercing, blanking, bending, and forming operations on metal or plastic sheet materials. The punch is the moving tool that pushes the material, while the die is the stationary tool that shapes or supports the workpiece.

High-quality Punch and Die Manufacturers provide complete solutions that usually include design, engineering simulation, material selection, machining, heat treatment, surface finishing, and trial stamping. By integrating these steps, they can deliver precise, long-life tooling that reduces downtime and ensures consistent part quality in high-volume production.

China's manufacturing ecosystem offers several advantages for sourcing from Punch and Die Manufacturers:

- Dense supply chain: Tool steels, carbide, coatings, heat treatment, and machining services are all clustered, which reduces lead time and cost.

- Advanced equipment: Many manufacturers have invested in CNC machining centers, grinding machines, EDM (wire and sinker), and CMMs, which support complex punch and die structures and tight tolerances.

- OEM-oriented service: Chinese Punch and Die Manufacturers understand global standards, support international drawings, and offer English-speaking sales and engineering teams.

For overseas brand owners, wholesalers, and producers, partnering with the right Punch and Die Manufacturer in China can mean faster tool delivery, extended tool life, and a more flexible supply chain.

U-Need Precision Machinery Co., Ltd. (U-NEED) stands out among Chinese Punch and Die Manufacturers as a comprehensive OEM partner that integrates precision CNC machining, metal stamping, plastic product manufacturing, silicone product manufacturing, and custom punch and die production into a unified solution. The company focuses on serving overseas brand owners, wholesalers, and manufacturers who require stable quality and responsive engineering support.

U-NEED operates as more than a typical punch and die shop: it is a multi-process manufacturing platform designed to handle complete projects from initial design input to finished components. This enables clients to centralize multiple product lines with one supplier instead of managing separate vendors for machining, stamping, and molding.

Key service scope includes:

- Custom punch and die sets for metal stamping applications

- High-precision CNC machined parts with tight tolerances

- Metal stamping parts for various industries

- Plastic components manufactured by injection molding

- Silicone products produced via compression or injection molding

Thanks to this structure, U-NEED can handle complex assemblies where a stamped metal frame, a plastic housing, and silicone seals must work together with precise dimensional relationships.

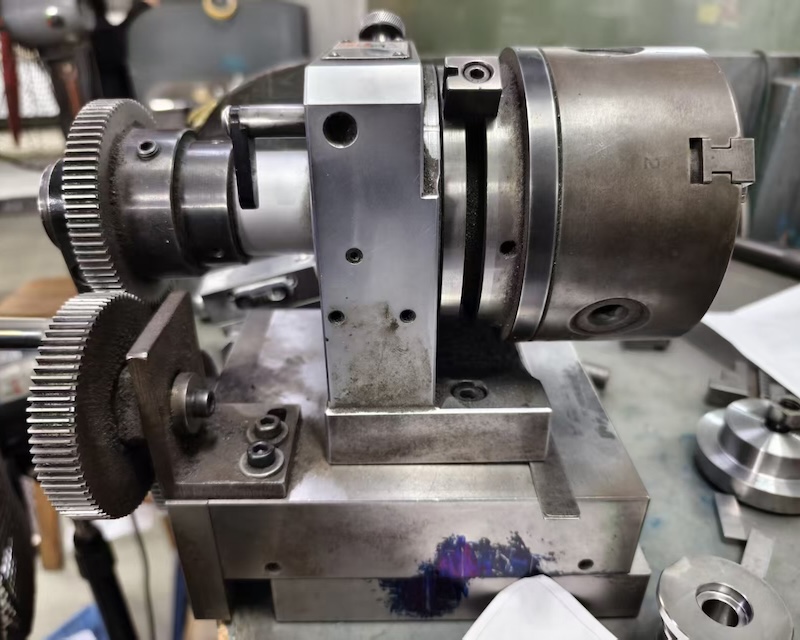

Punch and Die Manufacturers are judged heavily on machining capability, and U-NEED emphasizes high-precision CNC operations. The company works with multi-axis machining centers, turning centers, and support processes that can achieve fine finishes and consistent tolerance control. This precision is essential for punch and die components such as:

- Punch pins and punches with fine diameters

- Die inserts with complex profiles

- Guide posts, bushings, and plates requiring accurate alignment

By controlling both roughing and finishing stages in-house, U-NEED maintains reliable quality on critical punch and die surfaces that directly impact tool life and part quality in mass production.

Another advantage of U-NEED compared with many Punch and Die Manufacturers is its ability to process multiple materials and apply suitable surface treatments. The company works with:

- Alloy tool steels and high-speed steels for punch and die components

- Stainless steels and carbon steels for structural parts and carriers

- Aluminum alloys for lightweight fixtures and housings

- Engineering plastics for functional components and inserts

- Silicone materials for seals and cushioning elements

Surface treatments and coatings such as nitriding, polishing, plating, or other protective layers can be applied to improve wear resistance, corrosion resistance, or sliding performance. This is particularly important for punch and die sets that operate at high cycles, where friction and impact can rapidly damage unprotected surfaces.

Professional Punch and Die Manufacturers need consistent, documented quality control, and U-NEED emphasizes this area. The company typically conducts:

- Incoming material inspection to confirm material grade and hardness

- In-process inspections to verify critical dimensions during machining

- Final inspection using measuring tools such as micrometers, gauges, and coordinate measuring equipment

Dimensional accuracy, surface finish, hardness, and key functional features are checked before packaging and shipment. For foreign customers, inspection reports and measurement data can be provided to support internal quality audits and approval processes.

U-NEED's combination of punch and die manufacturing with plastic and silicone production is especially attractive for overseas customers seeking to consolidate their supplier base. Instead of purchasing punching tools from one company, plastic molds from another, and machined parts from a third, buyers can place all these related requirements with U-NEED and receive consistent quality, unified communication, and synchronized delivery.

Dongguan Yize Mould Co., Ltd. is a well-known specialist in precision mold components and belongs to the group of more focused Punch and Die Manufacturers. It supplies high-precision punch pins, die inserts, ejector pins, sleeves, and other standard or customized components for stamping and plastic molds.

Yize's strength lies in the manufacture of small, detailed components with high dimensional accuracy and fine surface finishes. This makes it suitable for customers who already design and assemble their own tools but need a reliable source for key punch and die components that are difficult to produce internally.

Wuxi Sundi Precision Tools Co., Ltd. provides a wide range of tooling products, including punch components, die components, and carbide wear parts, serving industries that require long-life, high-hardness tools. It is often selected by customers who need high-performance solutions in cutting, stamping, or forming processes.

As one of the specialized Punch and Die Manufacturers with a strong carbide background, Wuxi Sundi can offer tooling solutions that significantly extend the interval between maintenance, regrinding, or replacement, which is critical in high-volume production environments.

Dongguan MingYi Mold Parts Co., Ltd. focuses on standard and customized mold parts and is an important supplier to toolmakers and Punch and Die Manufacturers worldwide. Its portfolio includes guide posts, guide bushings, punch and die components, and other accessories that are used in stamping dies and injection molds.

MingYi's main advantage is its standardized product catalog combined with the ability to produce non-standard items, allowing customers to mix off-the-shelf parts with specialized components in a single order. This flexibility is highly valued by small and medium-sized tool shops, as well as repair and maintenance departments.

Zhuzhou Good Cemented Carbide Co., Ltd. is based in a region famous for carbide production and focuses on cemented carbide products and precision die components. For Punch and Die Manufacturers, carbide is a key material when long tool life and high wear resistance are required, especially for hard materials or abrasive production environments.

This company provides carbide inserts, punches, and other wear parts that can be integrated into larger tooling systems. Buyers working with high-strength steel, stainless steel, or high-volume stamping often consider Zhuzhou Good as a source for upgrading tool performance.

Hengshui Dongmo Precision Metal Products Co., Ltd. stands at the intersection between Punch and Die Manufacturers and stamping production companies. It not only makes stamping molds but also runs mass-production stamping lines, which allows customers to outsource both the tooling and the production of parts to one supplier.

This model is attractive for brands that do not want to invest in their own presses or stamping departments. They can work with Hengshui Dongmo to design the punch and die set, validate parts in trial runs, and then switch directly into mass production with the same partner.

Qingdao Hiparter Metal & Plastic Products Co., Ltd. offers a combination of stamping dies, progressive dies, plastic molds, and related manufacturing services. This dual capability in metal and plastic makes it comparable to full-service Punch and Die Manufacturers that also handle multi-material projects.

By providing both metal stamping tools and plastic molding tools, Hiparter can support applications where metal frameworks and plastic housings must match precisely, such as in electronics, automotive interior components, and consumer devices.

Shandong Xiaoya Precise Machinery Co., Ltd. is oriented toward larger and heavier tooling, especially vehicle stamping molds and related components. Although its scale and product type differ from typical small-part Punch and Die Manufacturers, it plays a major role in the automotive and heavy machinery sectors.

Customers with requirements for large body panels, structural components, or wheel-related parts often turn to companies like Xiaoya, where engineering teams and large-scale equipment can handle complex, high-tonnage stamping dies.

Dongguan Gude Precision Mold Co., Ltd. provides molds, mold parts, and precision metal products under flexible OEM and ODM models. It works closely with foreign customers to develop parts from concept to production, often blending its expertise in mold making with precision machining and stamping.

As a flexible supplier, Gude can support projects at different scales—ranging from small development batches to ongoing production—with an emphasis on communication, design support, and customized solutions.

Suzhou Jungu Precision Mould Co., Ltd. is specialized in fastener tooling, producing dies and punches for nuts, bolts, screws, and related hardware. While many Punch and Die Manufacturers cover a broad spectrum, Jungu's specialization in fastener dies gives it a strong position in this particular niche.

Fastener manufacturers rely on such specialized tooling to produce high-strength, dimensionally consistent products at high speed. Suzhou Jungu supports this by offering dedicated dies and punches tailored to specific fastener standards and customer requirements.

With so many Punch and Die Manufacturers in China, overseas buyers should apply a structured selection process to find the most suitable partner. The following points are especially important when evaluating suppliers:

A competent Punch and Die Manufacturer must have the right equipment to meet the required precision and complexity. Buyers should review:

- CNC machining centers and turning equipment, including capacity and maximum workpiece size

- Grinding, EDM, and drilling capabilities for internal features and tight radii

- Experience with complex geometries such as progressive dies, compound dies, or multi-step forming tools

Companies like U-NEED and other advanced shops invest in these capabilities to maintain accuracy and repeatability.

Punch and Die Manufacturers must understand tool steels, carbide, stainless steels, and sometimes aluminum or non-ferrous alloys for supporting structures. Ask candidates:

- Which tool steels they use for punches, dies, and inserts

- Whether they manage heat treatment internally or through certified partners

- Which surface treatments or coatings they can apply to improve wear resistance

The more varied the material and process expertise, the easier it is to optimize the tool for its specific application and expected production volume.

Quality control defines whether a punch and die will perform as designed. When comparing Punch and Die Manufacturers, look at:

- Measuring equipment (CMM, optical measurement, gauges) and calibration records

- Standard inspection procedures and documentation examples

- Ability to provide dimensional reports, hardness reports, and material certificates

Overseas OEMs often need these documents for their own quality systems, and they also show that the manufacturer takes process control seriously.

Effective communication is critical when developing custom tooling with Punch and Die Manufacturers in another country. Important aspects include:

- Clear English communication from sales and engineering teams

- Ability to interpret 2D drawings and 3D CAD data from international customers

- Willingness to offer design-for-manufacturing (DFM) suggestions to improve tool life or reduce cost

Suppliers such as U-NEED position themselves as engineering partners rather than simple build-to-print vendors, which is especially helpful for brands without deep tooling expertise.

While cost is important, it should be evaluated together with quality, tool life, and service support. When selecting Punch and Die Manufacturers, consider:

- Lead times for prototypes, first tools, and repeat orders

- Pricing structure for low-volume and high-volume projects

- After-sales service, including support for modifications, repairs, regrinding, and spare parts

Over the long term, a slightly higher initial tool price may actually reduce total cost if it delivers better reliability and lower downtime.

Given the range of Punch and Die Manufacturers in China, different projects may be better suited to different partners:

- Choose U-NEED when the project requires integrated machining, stamping, plastic components, and silicone parts under one coordinated OEM supplier, especially for multi-material assemblies.

- Choose a specialist such as Dongguan Yize or Zhuzhou Good when the main requirement is ultra-precise or carbide punch and die components that will be integrated into tools assembled elsewhere.

- Choose large-scale providers such as Shandong Xiaoya for automotive or large structural stamping tools.

- Choose integrated tooling-and-production suppliers like Hengshui Dongmo when you want both the tools and the ongoing stamped parts from a single source.

By matching project characteristics with the right type of Punch and Die Manufacturer, overseas buyers can achieve better quality, more competitive pricing, and smoother project execution.

Punch and Die Manufacturers in China have moved far beyond basic low-cost tooling and now provide sophisticated, high-precision solutions for global OEMs across many industries. Among them, U-Need Precision Machinery Co., Ltd. differentiates itself with a one-stop OEM model that unites precision machining, custom punch and die manufacturing, metal stamping, plastic production, and silicone product manufacturing. Alongside U-NEED, a diverse group of specialized suppliers covers areas such as carbide tooling, standard mold parts, large automotive dies, and fastener tooling, giving international buyers a broad choice of partners. By carefully evaluating technical capability, material expertise, quality control, communication, and long-term support, companies can select the most suitable Punch and Die Manufacturer in China and build a robust, efficient tooling supply chain.

Punch and Die Manufacturers in China serve industries such as automotive, consumer electronics, household appliances, medical devices, industrial machinery, and hardware. Their tools and stamped parts appear in components like brackets, connectors, housings, fasteners, and structural parts used in everyday products and industrial systems.

U-NEED supports overseas OEM customers by offering a complete combination of services: high-precision CNC machining, punch and die manufacturing, metal stamping, plastic molding, and silicone product manufacturing. With engineering support, flexible order quantities, and integrated project management, it helps foreign clients move from drawings to finished parts with fewer suppliers and smoother communication.

Before placing an order, buyers should check the manufacturer's equipment list, tolerance capabilities, and experience with similar products. They should also request samples or case studies, discuss materials and surface treatments, review inspection methods and documentation, and clarify lead times, payment terms, and after-sales support.

Many Punch and Die Manufacturers in China can handle small orders and prototype projects, including single-tool builds or small batches of parts. This flexibility allows overseas customers to test designs, validate tooling concepts, and make modifications before committing to large production runs, reducing risk and improving final product performance.

Language and distance barriers can be managed by choosing manufacturers with English-speaking teams, using clear technical drawings and 3D models, and maintaining regular communication through email and online meetings. Detailed specifications, tolerance requirements, and acceptance criteria should be documented at the start of the project, and both sides should agree on inspection standards and reporting formats to keep expectations aligned.