From 1 piece to mass production, our one-stop custom services ensure a worry-free experience for you.

Help Center

Views: 222 Author: Loretta Publish Time: 2025-12-26 Origin: Site

Content Menu

● What Is Selective Laser Sintering (SLS)?

● Core Advantages of SLS 3D Printing

● Typical SLS Materials and Applications

>> Typical SLS Application Areas

● Advantages and Limitations of SLS

>> SLS Strengths and Constraints

● Key Design Considerations for SLS Parts

>> Wall Thickness and Feature Size

>> Dimensional Tolerances and Shrinkage

>> Powder Removal and Internal Cavities

>> Orientation and Part Nesting

● Post Processing Options and Their Impact

>> Common Post Processing Steps

● When to Select SLS in Your Process Mix

>> Situations Where SLS Excels

>> Cases Where Other Processes May Be Better

● Latest Trends and Industry Insights

● Practical Workflow for OEM SLS Projects

>> Suggested SLS Project Steps

● Clear and Targeted Call to Action

>> 1. Is SLS strong enough for end use parts?

>> 2. How accurate is SLS compared with other 3D printing methods?

>> 3. Do SLS parts always need post processing?

>> 4. What is the main drawback of SLS for OEM projects?

>> 5. When should an OEM move from SLS to injection molding?

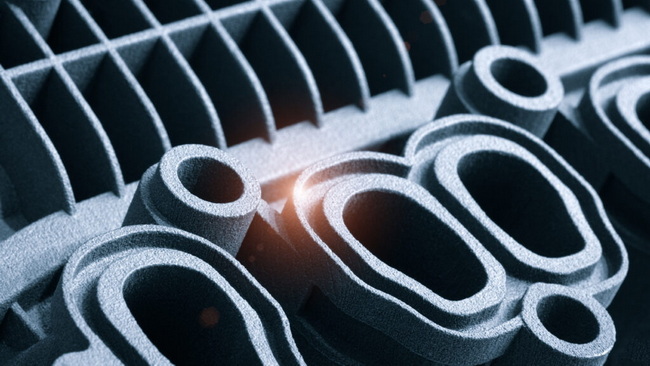

Selective Laser Sintering (SLS 3D printing) is a powder bed fusion technology that delivers strong, functional nylon parts with excellent design freedom, making it one of the most reliable options for rapid prototyping and low volume production in demanding industries. For OEM brands, wholesalers, and manufacturers, understanding the advantages and considerations of SLS is essential to choose the right manufacturing route and to collaborate efficiently with suppliers in China and worldwide.[1]

SLS is an additive manufacturing process that uses a high power laser to selectively fuse polymer powder, typically nylon, layer by layer into a solid 3D part. The unsintered powder surrounding the part supports the geometry during printing, eliminating the need for dedicated support structures.[2]

In a typical SLS workflow, a recoater spreads a thin layer of powder, the laser scans cross sections defined by the CAD model, and the build platform gradually lowers until the full part is built. After cooling, the powder cake is removed, parts are excavated, cleaned, and finished according to the application's cosmetic and performance requirements.[2]

SLS is widely viewed as an industrial grade 3D printing technology because it consistently delivers functional, end use parts. Its benefits are particularly attractive for OEMs who need repeatable quality without investing in molds and tooling.[2]

Key advantages of SLS include:

- Strong nylon parts suitable for functional testing and end use applications.[2]

- High design freedom for complex, organic, and lattice structures.[3]

- No dedicated supports, as the surrounding powder acts as a self support medium.[2]

- Efficient nesting of many parts in a single build for better throughput.[4]

- Attractive option for rapid prototyping and low to mid volume production without mold costs.[1]

SLS primarily uses engineering grade nylon powders, often modified with fillers or additives to tune performance. Modern SLS systems can also process flexible and specialty materials for more demanding use cases.[2]

- PA12 (Nylon 12): General purpose workhorse, strong and dimensionally stable for functional prototypes and end use parts.[2]

- PA11 (Nylon 11): Higher ductility and impact resistance, ideal for snap fits, hinges, and living joints.[2]

- Glass filled nylons: Increased stiffness and heat resistance for structural components and load bearing brackets.[4]

- TPU: Flexible, rubber like behavior for seals, cushions, grips, and protective elements.[5]

- Automotive: Brackets, clips, ducts, and housings for testing and short run production.[4]

- Medical and healthcare: Custom braces, orthoses, prosthetic components, and surgical guides.[2]

- Aerospace: Lightweight structural and semi structural parts where strength to weight ratio matters.[6]

- Consumer products: Wearables, eyewear frames, and customized accessories produced on demand.[3]

The following table summarizes the major strengths and constraints product teams should consider when evaluating this process.[7]

Aspect | SLS Strengths | SLS Limitations |

Design freedom | Complex geometries, internal channels, and lattices are easy to produce. | Very thin or fragile details may be damaged during depowdering. |

Supports | No dedicated support structures are required due to powder support. | Part packing must be carefully planned to avoid warping or parts fusing. |

Mechanical behavior | Nylon parts offer high strength and good fatigue resistance. | Some anisotropy and shrinkage can affect ultimate dimensional accuracy. |

Surface finish | Matte, uniform surfaces suitable for many functional uses. | Grainy texture may need finishing for cosmetic surfaces. |

Production speed | Multiple parts can be tightly nested to improve throughput. | Full print and cool down cycles can be relatively long. |

Cost structure | No tooling investment, ideal for evolving designs and low volumes. | Equipment and powder are relatively expensive, raising per part costs at scale. |

Scalability | Well suited to bridge production and custom batches. | Very high volumes often favor injection molding or stamping. |

Designing specifically for SLS reduces rework, improves reliability, and makes parts more cost effective. An intentional design approach is especially important for OEM projects involving assemblies and functional testing.[11]

- Keep minimum wall thickness within recommended ranges, often about 1.0 to 1.5 mm for PA12 depending on geometry.[12]

- Avoid large flat thin panels by adding ribs, fillets, or gentle curvature to improve stiffness and reduce warping.[9]

- Respect minimum hole diameters and gap sizes to ensure powder removal and avoid fused features.[2]

- Typical SLS tolerances are often around plus or minus 0.1 to 0.3 percent of nominal dimensions depending on the system and material.[4]

- Account for shrinkage during cooling, which experienced suppliers manage with process compensation.[8]

- For assemblies, allow adequate clearance or run test builds on critical features before release.[11]

- Closed internal cavities tend to trap unsintered powder that may not be removable.[2]

- For internal channels, include clean out holes and avoid extremely long narrow passages.[3]

- For printed in place mechanisms, leave sufficient clearances so moving elements do not fuse together.[9]

- Part orientation influences mechanical properties, cosmetics, and risk of distortion.[2]

- Coordinate with the manufacturing team so critical surfaces receive the most favorable orientation.[6]

- Efficient nesting of multiple parts in the build volume reduces per part costs, especially for small and medium batches.[4]

As printed SLS parts are functional, but post processing tailors appearance, feel, and performance to specific requirements. Selecting the right combination of finishing steps is important for both engineering and user experience.[8]

- Media or bead blasting: Removes residual powder and smooths the surface for a more uniform look.[2]

- Tumbling or mechanical polishing: Reduces roughness for consumer facing components.[6]

- Dyeing and painting: Enables consistent colors that match brand requirements or functional coding.[3]

- Infiltration and coating: Enhances surface seal, chemical resistance, or wear resistance when needed.[9]

Each additional step adds time and cost, so it is useful to distinguish between cosmetic zones and purely functional zones early in the design process.[7]

Choosing SLS is usually a strategic decision within a broader manufacturing mix that may include CNC machining, plastic molding, silicone molding, and metal stamping. Understanding where SLS fits best helps avoid unnecessary cost and lead time.[10]

- Rapid, functional prototypes that behave similarly to molded engineering plastics.[2]

- Projects where geometry changes frequently and tooling investment would be risky.[10]

- Designs with internal channels, lattices, or organic shapes that are difficult or expensive to machine or mold.[3]

- Low volume or customized batches produced on demand to minimize inventory.[4]

- Stable designs with high annual volumes that justify injection mold tooling and lower unit costs.[7]

- Components requiring extremely tight tolerances or specific machined finishes, favoring CNC machining.[10]

- Simple sheet metal forms that can be produced faster and cheaper via stamping or laser cutting.[13]

Recent developments in SLS focus on materials, productivity, and integration with other manufacturing methods. These trends influence how OEMs plan product life cycles and supply chains.[8]

- Broader material portfolios including advanced PA11, reinforced nylons, and flexible TPUs tailored for footwear, sports, and medical applications.[4]

- Larger SLS production farms in key manufacturing regions, improving pricing and lead times through scale.[14]

- Closer integration with traditional processes, where SLS parts support bridge production, jigs, fixtures, and low volume end use components.[6]

These developments make SLS a more attractive option for teams that need agility and want to avoid early tooling commitments.[8]

A structured workflow helps product teams move efficiently from idea to production while managing risk. Clear communication between design, engineering, and manufacturing functions is crucial at each stage.[15]

1. Define performance requirements

Clarify loads, temperature range, environment, and lifetime targets for each part. Distinguish cosmetic components from purely functional ones early in the process.[2]

2. Select material and process

Choose between PA12, PA11, glass filled nylon, or TPU based on stiffness, flexibility, and durability. Confirm whether SLS is the best fit or if CNC, molding, or stamping is more suitable.[10]

3. Design for SLS

Adjust wall thicknesses, radii, and fillets to meet printing guidelines and minimize warping. Add powder escape paths and avoid closed cavities that trap material.[11]

4. Prototype and iterate

Produce limited pilot batches to validate fit, ergonomics, and performance before finalizing geometry. Update tolerances and critical dimensions based on measured data.[15]

5. Scale to low volume production

Optimize nesting patterns to maximize build utilization and reduce unit cost. Standardize finishing steps so SLS parts align visually and functionally with components from other processes.[4]

If you are evaluating how to integrate SLS into your next product or component, review your drawings, expected volumes, and performance requirements, then share them with a trusted manufacturing partner to explore options. A responsive OEM focused supplier can help you compare SLS with CNC machining, plastic and silicone molding, and metal stamping, so you can select the most suitable process mix, optimize cost and lead time, and move your project from concept to market with greater confidence.

Yes, parts produced in PA12 or PA11 can achieve strength and durability comparable to many molded engineering plastics, which makes them suitable for various real world production applications.[2]

SLS can typically reach dimensional accuracy around plus or minus 0.1 to 0.3 percent of nominal size, which is competitive with other polymer 3D printing processes and sufficient for many assemblies.[4]

All parts require depowdering as a minimum, and many projects also benefit from bead blasting or dyeing, especially when surfaces are visible or need a more refined appearance.[8]

Key drawbacks include the relatively high cost of equipment and materials, the grainy as printed finish, and the need for careful post processing, all of which can increase price and lead time in some cases.[7]

Once design changes slow down and annual demand becomes high enough, injection molding frequently offers lower unit costs, while SLS remains valuable for early prototypes, bridge runs, and customized batches.[10]

[1](https://uptivemfg.com/advantages-and-considerations-of-selective-laser-sintering-sls/)

[2](https://formlabs.com/blog/what-is-selective-laser-sintering/)

[3](https://www.sculpteo.com/en/3d-learning-hub/3d-printing-technologies-and-processes/selective-laser-sintering/)

[4](https://www.unionfab.com/services/3d-printing/sls)

[5](https://www.china-3dprinting.com/sls-3d-printing/tpu-sls-printing.html)

[6](https://en.lab3d.dk/3d-print-vidensunivers/selektiv-lasersintring-sls)

[7](https://www.protolabs.com/resources/blog/advantages-and-disadvantages-of-selective-laser-sintering/)

[8](https://amchronicle.com/insights/guide-for-selective-laser-sintering/)

[9](https://www.hubs.com/knowledge-base/what-is-sls-3d-printing/)

[10](https://www.mfgproto.com/pros-and-cons-of-selective-laser-sintering/)

[11](https://www.stratasys.com/en/stratasysdirect/resources/resource-guides/selective-laser-sintering/)

[12](https://www.in3dtec.com/selective-laser-sintering-3d-printing/)

[13](https://jlc3dp.com)

[14](https://www.voxelmatters.com/20-chinese-3d-printing-companies-youll-need-to-know-in-2022/)

[15](https://www.simplemachining.com/blog/your-guide-to-sls-advantages-materials-and-best-practices-for-product-teams)

[16](https://prototaluk.com/blog/selective-laser-sintering-advantages-and-disadvantages/)