From 1 piece to mass production, our one-stop custom services ensure a worry-free experience for you.

Help Center

Views: 222 Author: Loretta Publish Time: 2025-12-20 Origin: Site

Content Menu

● Why Titanium Is Difficult to Machine

● Main Titanium Grades for CNC Machining

>> Commonly Machined Titanium Grades

● Benefits of CNC Machining Titanium

● Core Challenges in Titanium CNC Machining

>> Chip Evacuation and Chatter

● Recommended Cutting Parameters (Starting Ranges)

● Tool Materials and Coatings for Titanium

● Coolant Strategy and Chip Control

● Modern Machining Strategies for Titanium

>> High-Speed and Dynamic Milling

>> Hybrid and Laser-Assisted Machining

● Design for Manufacturability (DFM) of Titanium Parts

● Quality Control and Surface Requirements

● Typical Applications of CNC Machined Titanium

● Titanium Machining vs Other Metals

● Practical Checklist for Machining Titanium

● Why Choose U-NEED for Titanium CNC Machining

● Start Your Titanium Machining Project with U-NEED

● FAQ About Machining Titanium

>> 1. Is titanium harder to machine than stainless steel?

>> 2. What is a good cutting speed for Ti-6Al-4V?

>> 3. How can tool life be improved when machining titanium?

>> 4. Which titanium grades are most common in CNC machining?

>> 5. Can titanium parts be combined with plastic, silicone, or stamped metal components?

Titanium machining is essential for aerospace, medical, energy, and high-performance industrial parts that demand low weight, high strength, and excellent corrosion resistance. With the right titanium grade selection, cutting parameters, tooling, and machining strategy, it is possible to achieve stable production, long tool life, and precise tolerances while keeping costs under control. U-NEED supports global brands, wholesalers, and manufacturers with OEM titanium machining services for complex components and small to medium batch production.[1][2][3]

Titanium machining uses CNC milling, turning, drilling, boring, and other processes to remove material from titanium and its alloys to create precision parts. These processes must be adapted to titanium's special properties such as low thermal conductivity, high chemical reactivity, and relatively low modulus of elasticity.[2][4][5]

Common titanium machining processes:

- CNC milling for 3-axis to 5-axis prismatic and freeform parts.[1][2]

- CNC turning for shafts, rings, and cylindrical aerospace or medical parts.[5][2]

- Drilling, tapping, and boring for deep holes and high-strength threaded features.[2][1]

- Finishing operations including deburring, polishing, and surface treatment preparation.[5][2]

Titanium is not extremely hard, but its machinability is poor because of how it behaves under cutting conditions. Understanding these mechanisms is the first step toward robust titanium CNC machining.[3][2]

Main reasons titanium is difficult to machine:

- Low thermal conductivity: Heat stays near the cutting edge instead of flowing into the chip or workpiece, causing high tool temperature and rapid wear.[4][2]

- High chemical reactivity: At machining temperatures, titanium tends to weld to the tool, creating built-up edge and unstable cutting.[6][4]

- Low modulus of elasticity: Titanium tends to deflect away from the tool, increasing chatter and dimensional error.[4][2]

- Work hardening tendency: Rubbing instead of cutting creates a hardened surface layer that damages tools in later passes.[6][4]

Selecting the correct titanium grade is critical because mechanical properties, corrosion resistance, and machinability differ significantly. The best choice depends on application requirements such as strength, fatigue life, and regulatory standards.[1][5]

1. Grade 2 (commercially pure):

- Good formability and excellent corrosion resistance.

- Used in chemical equipment, marine components, and general industrial parts.[7][3]

2. Grade 5 (Ti-6Al-4V):

- The most widely used titanium alloy, offering high strength and good fatigue performance.[8][3]

- Standard material for aerospace, medical devices, and high-performance mechanical parts.[5][1]

3. Grade 23 (Ti-6Al-4V ELI):

- Extra-low interstitial version of Grade 5, with improved fracture toughness and biocompatibility.[9][1]

- Ideal for implants and critical medical or aerospace components.[1][5]

4. High-temperature alloys (e.g., Ti-6242, Ti-5553):

- Designed for high-temperature aerospace components requiring strength at elevated temperatures.[10][3]

Despite higher machining difficulty, titanium provides exceptional performance where weight, corrosion, and biocompatibility matter most. When designed and machined correctly, titanium parts often outperform steel, stainless steel, and aluminum in demanding environments.[11][2]

Key benefits of titanium parts:

- High strength-to-weight ratio: Enables lightweight components that can carry high structural loads in aerospace and motorsport applications.[3][2]

- Excellent corrosion resistance: Performs reliably in seawater, chemical processing, and aggressive service conditions.[11][2]

- Biocompatibility: Well suited for implants, surgical instruments, and devices contacting human tissue.[2][1]

- Heat and fatigue resistance: Maintains strength at elevated temperatures and under cyclic loading.[8][3]

Titanium machining success depends on controlling heat, chip flow, vibration, and tool wear. Poor control in any of these areas quickly leads to scrap, downtime, and excessive tooling cost.[3][2]

- Localized heat at the cutting edge causes plastic deformation and coating breakdown on tools.[4][2]

- Tool life drops sharply if surface speed is too high or if coolant application is ineffective.[12][3]

- Long, stringy chips can wrap around the tool, damaging the workpiece and increasing heat.[2][5]

- Chatter and deflection appear easily on thin-wall or slender titanium parts due to lower stiffness.[4][2]

Exact cutting parameters depend on titanium grade, tool material, machine rigidity, and coolant system, but starting windows help process engineers tune their programs. Always verify and adjust on the actual machine.[13][1]

Typical starting ranges:[14][13]

- Cutting speed: 30-60 m/min (about 100-200 SFM) with coated carbide tools.

- Feed per tooth: 0.10-0.25 mm/tooth, depending on tool diameter and setup stiffness.

- Axial depth of cut: 0.5-1.5 mm for finishing and moderate roughing.

- Radial engagement: Prefer low radial engagement with higher axial depth (dynamic milling).

Typical ranges:[13][3]

- Cutting speed: 40-80 m/min for coated carbide inserts.

- Feed rate: 0.15-0.3 mm/rev for roughing, lower for finishing.

- Depth of cut: 1-4 mm for roughing; 0.2-0.8 mm for finishing.

Choosing the right tool material and coating is critical for controlling wear and maintaining dimensional accuracy. Titanium machining places extreme thermal and mechanical loads on cutting tools.[15][4]

Effective tooling options:

1. Coated carbide tools:

- TiAlN, AlTiN, and similar high-performance coatings improve heat resistance and wear in titanium.[16][12]

- Coatings reduce friction, help prevent built-up edge, and protect the substrate at elevated temperatures.[12][4]

2. Sharp positive-rake geometries:

- Lower cutting forces and reduce heat generation during chip formation.[15][4]

- Important for minimizing work hardening and avoiding tool chipping.

3. Special titanium end mills and inserts:

- Flute design and edge prep tailored to chip evacuation and vibration control in titanium alloys.[6][4]

An optimized coolant and lubrication strategy significantly extends tool life and improves stability in titanium machining. Coolant must remove heat effectively and support reliable chip evacuation.[15][2]

Best practices for coolant and chips:

1. High-pressure coolant (HPC):

- Directs coolant into the cutting zone, breaks chips, and flushes them away from the tool and workpiece.[17][15]

- Pressures of 70 bar or more are often used in aerospace titanium operations.

2. High-performance fluids:

- Advanced emulsions and synthetics with high lubricity can increase productivity by around 40% and extend tool life by 150% in documented titanium case studies.[18][17]

3. Chip breaking techniques:

- Use chip-breaker inserts, peck cycles for drilling, and step-over strategies designed for short, controlled chips.[6][2]

Modern CAM strategies and hybrid processes have transformed titanium machining productivity. Instead of heavy conventional roughing, many shops now emphasize constant engagement and controlled heat.[12][8]

- High-speed machining with low radial engagement keeps chip thickness and tool loading consistent.[19][13]

- Trochoidal and dynamic milling paths allow higher feed rates, reduced heat, and improved tool life in titanium roughing.[13][1]

- Laser-assisted machining locally heats titanium, reducing cutting forces and allowing higher speeds for some alloys.[8][12]

- Research shows these approaches can extend tool life by several times compared with conventional processes in difficult titanium machining operations.[12][8]

Good DFM decisions reduce machining difficulty, cycle time, and overall part cost. Engineers should involve their machining partner early to adjust features before locking the design.[5][1]

DFM tips for titanium CNC parts:

- Avoid ultra-thin walls and extremely deep pockets that increase deflection and chatter.[3][2]

- Use larger internal fillet radii and avoid sharp internal corners to enable stronger, more rigid tools.[1][5]

- Standardize hole sizes and thread forms to match available drills and taps for titanium.[2][1]

- Consider splitting complex monolithic parts into multiple components if this reduces machining risk and cost while still meeting performance requirements.[20][3]

High-value titanium parts typically require tight tolerances and careful control of surface integrity. Inspection planning should be aligned with industry standards for aerospace, medical, and critical industrial components.[8][3]

Typical quality and inspection elements:

- Dimensional and geometric tolerances:

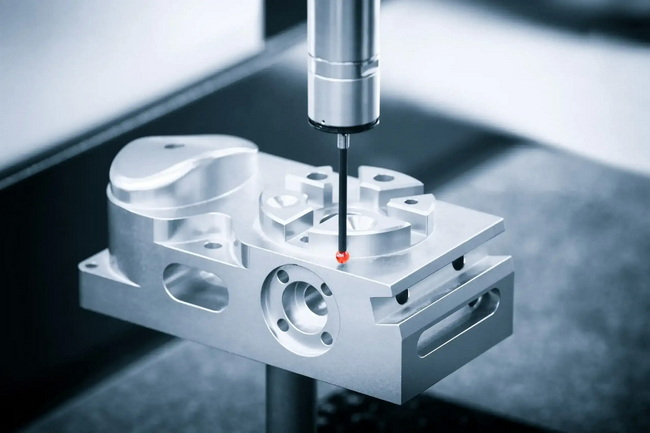

- CMM inspection for position, flatness, concentricity, and complex GD&T callouts.[5][3]

- Surface roughness:

- Many titanium parts require Ra values below 1.6 μm on sealing or mating surfaces, and even lower for medical components.[8][2]

- Non-destructive testing (NDT):

- Dye-penetrant or other NDT methods for fatigue-critical parts in aerospace and medical sectors.[3][8]

Titanium's strength, low density, corrosion resistance, and biocompatibility support a wide range of applications. CNC machining is ideal for lower-volume and high-complexity titanium parts across multiple industries.[11][2]

Representative applications:

- Aerospace: Structural brackets, landing gear components, engine parts, seat frames, and hydraulic fittings.[10][3]

- Medical: Bone plates, screws, joint components, dental implants, and surgical instruments.[1][2]

- Energy and marine: Offshore components, valve bodies, pump housings, and heat-exchanger elements.[11][2]

- Automotive and industrial: Racing components, high-strength fasteners, and corrosion-resistant fittings and housings.[20][2]

The table below provides a quick machinability comparison between titanium, alloy steel, stainless steel, and aluminum. This helps engineers understand why titanium requires a different process window.[2][3]

Table: Machinability Comparison of Common Materials

Material | Machinability (relative) | Typical Cutting Speed Range | Tool Wear Tendency | Main In-Use Advantages | Main Machining Challenge |

Titanium alloys | Low | 30-80 m/min | High | Strength-to-weight, corrosion, bio-use | Heat concentration, chip control |

Alloy steels | Medium | 80-180 m/min | Medium | Strength, cost, availability | Tool wear at higher hardness |

Stainless steels | Medium-low | 60-140 m/min | Medium-high | Corrosion, temperature resistance | Work hardening, chip breaking |

Aluminum alloys | High | 200-600 m/min | Low | Easy machining, low density | Built-up edge at high speed |

A concise checklist helps engineers and buyers confirm that key factors are addressed before titanium mass production.[15][2]

1. Confirm the correct titanium grade based on strength, environment, and regulatory needs.[21][9]

2. Use dedicated titanium tooling with appropriate coatings and sharp geometry.[4][12]

3. Set conservative speeds with higher feed per tooth to avoid rubbing.[19][13]

4. Apply high-pressure coolant and verify chip evacuation on every operation.[17][15]

5. Use dynamic or trochoidal milling toolpaths for efficient roughing.[13][1]

6. Maximize rigidity by reducing tool overhang and using robust fixturing.[4][2]

7. Monitor tool wear patterns and adjust parameters or tool paths as needed.[12][3]

U-NEED is a China-based OEM manufacturer specializing in high-precision machined parts, plastic product manufacturing, silicone product manufacturing, and metal stamping. This combination of processes allows U-NEED to support complete assemblies that integrate titanium components with plastic, silicone, or stamped metal parts for global brands, wholesalers, and manufacturers.

Key strengths of U-NEED for titanium projects:

- Proven experience with titanium and other difficult-to-machine materials for aerospace, medical, and industrial applications.[10][2]

- CNC milling and turning capabilities suitable for prototypes, engineering validation, and small to medium batch production.[22][5]

- Integrated OEM services including precision machining, molding, and stamping to reduce supplier count and coordination effort.

- Quality-driven approach with inspection, material traceability, and surface finishing support aligned to customer standards.[23][3]

If your next project requires high-precision titanium parts with stable quality, controlled cost, and reliable lead time, choosing a specialized CNC machining partner is critical. U-NEED works closely with international OEM customers from early design review through to mass production to optimize manufacturability and reduce project risk.[11][2]

To get started with U-NEED today:

- Prepare your 3D models, 2D drawings, and key requirements (titanium grade, quantity, tolerances, and surface finish).

- Contact U-NEED via the company website or email to request a professional DFM review and quotation for titanium CNC machining and related processes.

- Collaborate with U-NEED's engineering team to refine design details, confirm process capability, and move efficiently from prototype to stable production.

Take the next step now and reach out to U-NEED for a targeted titanium machining solution that supports your brand's performance, reliability, and time-to-market goals.

Yes. Titanium's low thermal conductivity, high reactivity, and greater tendency to deflect make it more difficult to machine than most stainless steels, especially at higher speeds. With proper tooling, parameters, and coolant strategy, stable and repeatable titanium machining is still achievable.[3][2]

For most coated carbide tools, a useful starting range is 30-60 m/min for milling and 40-80 m/min for turning. Final values should be tuned based on machine rigidity, tool type, coolant delivery, and surface finish requirements.[13][3]

Use sharp, coated carbide tools, maintain constant chip load, avoid rubbing, and apply high-pressure coolant directly at the cutting zone. Many shops also adopt dynamic milling strategies and advanced coolants that have been shown to increase tool life by more than 100% in titanium.[17][15][12]

Grade 2 (commercially pure) and Grade 5 (Ti-6Al-4V) are the most widely used grades for CNC machining. Grade 23 (Ti-6Al-4V ELI) is particularly popular in medical applications that demand high toughness and biocompatibility.[9][5][1]

Yes. Titanium CNC parts are often assembled with plastic, silicone, and stamped metal components in complex products such as medical devices, automotive modules, and industrial equipment. OEM suppliers like U-NEED can support these multi-material assemblies within a single integrated supply chain.[24][2]

[1](https://www.fictiv.com/articles/titanium-cnc-machining-a-complete-a-z-expert-guide)

[2](https://www.3erp.com/blog/titanium-cnc-machining/)

[3](http://www.scielo.org.za/scielo.php?script=sci_arttext&pid=S2309-89882010000100001)

[4](https://www.gwstoolgroup.com/the-titanium-playbook-advanced-tools-and-tactics-for-challenging-alloys/)

[5](https://waykenrm.com/blogs/cnc-machining-titanium/)

[6](https://www.morecuttingtools.com/news/titanium-alloy-machining-guide.html)

[7](https://www.makino.com/makino-us/media/general/Machining-Titanium-Part-3.pdf)

[8](https://www.sciencedirect.com/science/article/abs/pii/S0890695509002168)

[9](https://www.rapid-protos.com/titanium-cnc-machining-guide/)

[10](https://www.sme.org/titanium-machining-evolves)

[11](https://www.secotools.com/article/a_guide_to_titanium_machining?language=en)

[12](https://www.sciencedirect.com/science/article/pii/S2212827119307954)

[13](https://www.ptsmake.com/how-to-effectively-machine-titanium-grade-5-ti-6al-4v/)

[14](https://yijinsolution.com/cnc-guides/titanium-cnc-machining/)

[15](https://www.secotools.com/article/n8_tips_to_machine_titanium_alloys?language=en)

[16](https://www.sumitool.com/en/downloads/assets/mt-catalog/IN541.pdf)

[17](https://home.quakerhoughton.com/wp-content/uploads/2022/03/cs_hocut_4940_150per-increase-tool-life_EN_GL.pdf)

[18](https://home.quakerhoughton.com/wp-content/uploads/2021/09/caso-de-estudio_Hocut-4940_150percent-increase-tool-life_A4_EN_GL.pdf)

[19](https://www.cnccookbook.com/how-to-machine-titanium/)

[20](https://www.radical-departures.net/articles/advances-in-titanium-machining/)

[21](https://prototek.com/article/what-are-the-different-grades-of-titanium-for-machining/)

[22](https://www.protolabs.com/services/cnc-machining/titanium/)

[23](https://astromachineworks.com/guide-to-machining-titanium/)

[24](https://www.makerverse.com/resources/cnc-machining-guides/cnc-machining-with-titanium/)

[25](https://www.perplexity.ai/search/95d47620-81fc-483e-821c-a398249c900b)

[26](https://www.harveyperformance.com/in-the-loupe/titanium-machining/)

[27](https://tirapid.com/machining-titanium/)

content is empty!